Abstract

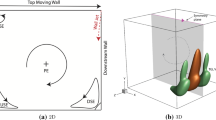

This paper presents the two-dimensional (2D) steady incompressible flow in a lid-driven sectorial cavity. In order to analyze the flow structures, the 2D Navier–Stokes equations are solved by using the finite element method. Different cases of the cavity aspect ratio A and three cases of the speed ratios \((S=-1,0,1)\) of the upper and the lower lids are considered. The finite element formulation for the governing equations is adopted via the velocity-pressure formulation. By varying A for each S, the effect of the Reynolds number on the streamline patterns and their bifurcations are investigated in range \(Re\in [0,200]\). A comparison between the obtained results and some earlier studies is presented.

Similar content being viewed by others

Abbreviations

- \(r_{1},r_{2}\) :

-

radius of the inner and outer circles respectively

- A :

-

cavity aspect ratio = \(r_{2}/r_{1}\)

- \(2{\alpha }\) :

-

angle of the sector

- u :

-

dimensionless fluid velocity

- \(U_{1},U_{2}\) :

-

speed of the upper and lower lids respectively

- S :

-

speed ratio of the moving lids = \(U_{2}/U_{1}\)

- \(\psi \) :

-

streamfunction

- Re:

-

Reynolds number

References

Aksouh, A., Mataoui, A., Seghouani, N.: Low Reynolds-number effect on the turbulent natural convection in an enclosed 3D tall cavity. Prog. Comput. Fluid Dyn. Int. J. 12, 389–399 (2012)

Armellini, A., Casarsa, L., Giannattasio, P.: Low Reynolds number flow in rectangular cooling channels provided with low aspect ratio pin fins. Int. J. Heat Fluid Flow 31, 689–701 (2010)

Burggraf, O.: Analytical and numerical studies of the structure of steady separated flows. J. Fluid Mech. 24, 113–151 (1966)

Burnett, S.D.: Finite element analysis: from concepts to applications. Addison-Wesley, Reading, Ma (1987)

Chebbi, B., Tavoularis, S.: Low Reynolds number flow in and above asymmetric, triangular cavities. Phys. Fluids (A) 2, 1044–1046 (1990)

Chiang, T.P., Sheu, W.H., Hwang Robert, R.: Effect of the Reynolds number on the eddy structure in a lid-driven cavity. Int. J. Numer. Methods Fluids 26, 557–579 (1998)

Coyle, D.J.: The fluid mechanics of roll coating: steady flows, stabihty, and rheology, Ph.D. thesis, University of Minnesota (1984)

Darr, J.H., Vanka, S.P.: Separated flow in a driven trapezoidal cavity. Phys. Fluids (A) 3, 385–392 (1991)

Deliceoğlu, A., Aydın, S.H.: Flow bifurcation and eddy genesis in an L-shaped cavity. Comput. Fluids 73, 24–46 (2013)

Faraz, N.: Study of the effects of the Reynolds number on circular porous slider via variational iteration algorithm-II. Comput. Math. Appl. 61(8), 1991–1994 (2011)

Erturk, E., Corke, T.C., Gökçöl, C.: Numerical solutions of 2-D steady incompressible driven cavity Flow at high Reynolds numbers. Int. J. Numer. Methods Fluids 48, 747–774 (2005)

Gaskell, P.H., Gürcan, F., Savage, M.D., Thompson, H.M.: Stokes flow in a double-lid-driven cavity with free surface side-walls. Proc. Inst. Mech. Eng Part C J. Mech. Eng. Sci. 212(C5), 387–403 (1998)

Gaskell, P.H., Savage, M.D., Wilson, M.: Flow structures in a half-filled annulus between rotating co-axial cylinders. J. Fluid Mech. 337, 263–282 (1997)

Gürcan, F.: Effect of the Reynolds number on streamline bifurcations in a double-lid-driven cavity with free surfaces. Comput. Fluids 32, 1283–1298 (2003)

Gürcan, F., Bilgil, H.: Bifurcations and eddy genesis of Stokes flow within a sectorial cavity. Eur. J. Mech. B/Fluids 39, 42–51 (2013)

Gürcan F., Bilgil H., Şahin A.: Bifurcations and eddy genesis of Stokes flow within a sectorial cavity PART II: co-moving lids. Eur. J. Mech. B/Fluids. doi:10.1016/j.euromechflu.2015.02.008

Hellebrand H.: Tape casting. In: Brook, R.J. (ed.) Materials science and technology-processing of ceramics, vol. 17A, pp. 189–260. VCH Publishers Inc., New York (1996)

Higgins B.G.: Dynamics of coating, adhesion and wetting. Status Report Project 3328. The Institute of Paper Chemistry, pp. 69–74 (1982)

Oztop, H.F., Dagtekin, I.: Mixed convection in two-sided lid-driven differentially heated square cavity. Int. J. Heat Mass Transf. 47, 1761–1769 (2004)

Pan, F., Acrivos, A.: Steady flows in rectangular cavities. J. Fluid Mech. 28, 643–655 (1967)

Rao S.S.: The finite element method in engineering. Elsevier Science & Technology Books (2004)

Schewe, G.: Reynolds-number effects in flow around a rectangular cylinder with aspectratio 1:5. J. Fluids Struct. 39, 15–26 (2013)

Vanka, S.P.: Block-implicit multigrid solution Navier-Stokes equations in primitive variables. J. Comput. Phys. 65, 138–158 (1986)

Walicka, A., Falicki, J.: Reynolds number effects in the flow of an electrorheological fluid of a Casson type between fixed surfaces of revolution. Appl. Math. Comput. 250, 636–649 (2015)

Author information

Authors and Affiliations

Corresponding author

Appendix: Construction of shape functions

Appendix: Construction of shape functions

To facilitate the construction of shape functions, an isoparametric mapping which maps (x, y) cartesian coordinates to \((\xi ,\eta )\) local coordinates was used. In addition, curved-sides elements are quite useful in practice, principally for modeling curved boundaries. Due to this facilities, isoparametric mapping was used rather than direct approach (for more details see [4]).

Figure 15a shows the parent element in \(\xi ,\eta \)-space; Fig. 15b shows the parent element mapped onto a curved-sided real element in x, y-space. Firstly, the parent element was examined, then the shape functions are developed on the parent element and finally the mapping of the parent element onto the real element was constituted. The latter, results in the parent shape functions was mapped into shape functions on the real element.

The parent element may have any triangular shape. However, a regular shape is desirable because real elements that are severely distorted from the parent shape cause numerical problems. Therefore, regularly shaped reel elements are generally most useful. We selected a isosceles triangle, due to it’s computation advantages (see [4]).

The parent shape functions are developed by using the interpolation property \(\phi _{i}(\xi _{i},\eta _{i})=\delta _{ij.}\) The trial solution in the parent element is a complete 2-D polynomial, then each shape function may contain any of the terms in a 2-D polynomial. Thus, for node 1,

where the interpolation property requires that

Applying conditions Eqs. (21) to (20) yields six equations:

solving Eq. (22) yields

and in a similar fashion it shown that

and for pressure,

These shape functions are identical for each element.

There are several ways to establish such a mapping. The most widely used at present is the isoparametric approach

The Jacobian plays an important role in the FE analysis of isoparametric elements. The analytical test for acceptability of the 2-D mapping is

where \(\left| J^{(e)}(\xi ,\eta )\right| \) is the Jacobian, which is the determinant of the Jacobian matrix (i.e., the Jacobian must be positive everywhere inside the element and on the boundary, see [4]). The Jacobian in 2-D is the ratio of an infinitesimal area in the parent element to the corresponding infinitesimal area in the real element that it is mapped into:

The Jacobian matrix is given by

Hence

The derivatives of the coordinate transformation are obtained from Eq. (26):

and the derivatives of the shape functions are obtained from Eqs. (23) and (24). In addition, the derivatives \(\frac{\partial \phi _{i}^{(e)}}{\partial x}\) and \(\frac{\partial \phi _{i}^{(e)}}{\partial y}\) are obtained by using the chain rule:

Hence

Equation (32) can be written as:

where \(\left[ J^{(e)}\right] ^{-1}\) is inverse of the Jacobian matrix in Eq. (29).

About this article

Cite this article

Bilgil, H., Gürcan, F. Effect of the Reynolds number on flow bifurcations and eddy genesis in a lid-driven sectorial cavity. Japan J. Indust. Appl. Math. 33, 343–360 (2016). https://doi.org/10.1007/s13160-016-0212-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13160-016-0212-1