Abstract

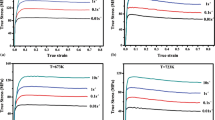

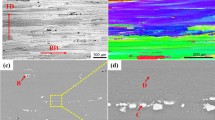

To fill the gap in the study of hot working properties of materials under complex stress and strain states, novel shear compression specimens were introduced to study the hot deformation behavior of 7055 aluminum alloy through the Gleeble-3500 thermal simulation machine. The flow curves were obtained using the Mises equivalent equation, and the processing maps were made. In addition, the microstructures after deformation were analyzed with OM and EBSD techniques. The results showed that the effect of shear-compression deformation was mainly at the oblique slots of the specimen, where the peak stress was 1.5 times that in the uniaxial compression test at 450 °C-0.01 s−1. The stress rose to the peak and then continued to fall with strain, while the steady-state flow phenomenon only appeared at high temperatures and low rates. The processing maps showed that the desired hot working area was at 450 °C-5 s−1, and the organization analysis supports this result. It was found that higher temperatures would significantly increase the uniformity of organization in the narrow gap region. Higher strain rates would promote dynamic recrystallization (DRX) nucleation at high temperatures and effectively discourage DRX grain growth.

Similar content being viewed by others

References

Zhang P, Li Y, Liu Y, Zhang Y, and Liu J, Vacuum 171 (2020) 109005. https://doi.org/10.1016/j.vacuum.2019.109005

Jia Z, Xie Z, Xiang K, Ding L, Weng Y, and Liu Q, Mater Charact 183 (2022) 111619. https://doi.org/10.1016/j.matchar.2021.111619

Wang X, Pan Q, Xiong S, Liu L, Sun Y, and Wang W, Trans Nonferrous Metals Soc China 28 (2018) 1484–1494. https://doi.org/10.1016/S1003-6326(18)64789-2

Tang J, Yu B, Zhang J, Xu F, and Bao C, Trans Nonferrous Metals Soc China 30 (2020) 1227. https://doi.org/10.1016/S1003-6326(20)65291-8

Lv L, Shao L, Lin H, and Jin T, Mater Today Commun 31 (2022) 103551. https://doi.org/10.1016/j.mtcomm.2022.103551

Zhou L, Jiang B, Cui T, Zhang D, He J, and Liu Y, J Iron Steel Res Int 21 (2014) 1111. https://doi.org/10.1016/S1006-706X(14)60191-6

Liang X K, Sun X J, Liu Q Y, and Dong H, Acta Metall Sin (Engl Lett) 19 (2006) 265. https://doi.org/10.1016/S1006-7191(06)60054-9

Lin G, Zheng X, Yang W, Feng D, and Peng D, Acta Metallurgica Sin (Engl Lett) 22 (2009) 110–116. https://doi.org/10.1016/S1006-7191(08)60077-0

Liu S, Wang S, Ye L, Deng Y, and Zhang X, Mater Sci Engg: A 677 (2016) 203. https://doi.org/10.1016/j.msea.2016.09.047

Kumar R, Singh Bhadauria S, Sharma V, and Kumar M, Mater Today Proc (2022). https://doi.org/10.1016/j.matpr.2022.10.111

Eivani A R, Jafarian H R, and Zhou J, J Manuf Process 57 (2020) 881–892. https://doi.org/10.1016/j.jmapro.2020.07.011

Luo R, Cao Y, Qiu Y, Yuan Z, Li S, and Cheng X, Xiyou Jinshu/Chin J Rare Metals 46 (2022) 144. https://doi.org/10.13373/j.cnki.cjrm.XY19110013

Rittel D, Lee S, and Ravichandran G, Exp Mech 42 (2002) 58. https://doi.org/10.1007/BF02411052

Moemeni S, Zarei-Hanzaki A, Abedi H R, and Torabinejad V, Exp Mech 52 (2012) 629. https://doi.org/10.1007/s11340-011-9525-9

Sang D, Fu R, Wang Y, and Li Y, Mater Sci Eng: A 747 (2019) 130. https://doi.org/10.1016/j.msea.2018.12.059

Luo R, Cao Y, Bian H, Chen L, Peng C-T, Cao F, et al., Mater Charact 178 (2021) 111203. https://doi.org/10.1016/j.matchar.2021.111203

El-Shenawy E H, Mater Today Proc 28 (2020) 998. https://doi.org/10.1016/j.matpr.2019.12.339

Yu D J, Xu D S, Wang H, Zhao Z B, Wei G Z, and Yang R, J Mater Sci Technol 35 (2019) 1039–1043. https://doi.org/10.1016/j.jmst.2018.12.026

Xu L, Zhou D, Xu C, Zhang H, Qu W, Xie P, et al., Mater Today Commun 34 (2023) 105138. https://doi.org/10.1016/j.mtcomm.2022.105138

Ma H, Lu K, and Liu X, Structures 47 (2023) 1250–1264. https://doi.org/10.1016/j.istruc.2022.11.017

Dorogoy A, and Rittel D, Exp Mech 45 (2005) 167. https://doi.org/10.1007/BF02428190

Dorogoy A, and Rittel D, Exp Mech 45 (2005) 178. https://doi.org/10.1007/BF02428191

Shao Y, Shi J, Pan J, Liu Q, Yan L, and Guo P, Mater Today Commun 31 (2022) 103593. https://doi.org/10.1016/j.mtcomm.2022.103593

Chegini M, Aboutalebi M R, Seyedein S H, Ebrahimi G R, and Jahazi M, J Manuf Process 56 (2020) 916. https://doi.org/10.1016/j.jmapro.2020.05.008

Deng L, Zhang H, Li G, Tang X, Yi P, Liu Z, et al., Trans Nonferrous Metals Soc China 32 (2022) 2150–2163. https://doi.org/10.1016/S1003-6326(22)65937-5

Khorshidi H, Kermanpur A, Rastegari H, Ghassemali E, and Somani M C, Mater Today Commun 27 (2021) 102352. https://doi.org/10.1016/j.mtcomm.2021.102352

Shi Z, Yan X, Duan C, Song J, Zhao M, and Wang J, J Iron Steel Res Int 24 (2017) 625. https://doi.org/10.1016/S1006-706X(17)30094-8

Qunying Y, Wenyi L, Zhiqing Z, Guangjie H, and Xiaoyong L, Rare Metal Mater Eng 47 (2018) 409. https://doi.org/10.1016/S1875-5372(18)30080-8

Chen L, Ding H, Liu T, Luo R, Cao Y, Zhang Y, et al., Mater Des 212 (2021) 110195. https://doi.org/10.1016/j.matdes.2021.110195

Luo R, Cao Y, Cui S, Cao Y, Peng C-T, Yang Y, et al., Trans Indian Inst Metals 74 (2021) 1809. https://doi.org/10.1007/s12666-021-02259-w

Sang D, Fu R, and Li Y, Mater Charact 122 (2016) 154. https://doi.org/10.1016/j.matchar.2016.10.025

Zhang J, Yi Y, Huang S, Mao X, He H, Tang J, et al., Mater Sci Eng: A 804 (2021) 140650. https://doi.org/10.1016/j.msea.2020.140650

Acknowledgements

This work was financially supported in part by the Natural Science Foundation of Jiangsu Province (BK20220548); Graduate Research and Innovation Projects of Jiangsu Province (SJCX22_1860); the State Key Laboratory of Mechanical Transmissions Project (SKLMT-MSKFKT-202219)

Author information

Authors and Affiliations

Contributions

RL contributed to conceptualization, funding acquisition, writing—review & editing, and methodology. YZ and TL done investigation and writing—original draft. YQ, TT, and YY helped in visualization. LC and ZZ done investigation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, R., Zhou, Y., Liu, T. et al. Hot Working Property Study of 7055 Aluminum Alloy Based on Hot Shear-Compression Deformation. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-023-03226-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-023-03226-3