Abstract

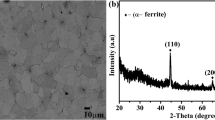

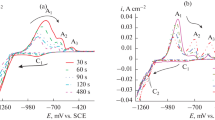

In the current study, Zn electrodeposition was done from an acidic sulfate bath onto mild steel at a pH of 3.5. The Zn coating was done in both direct current (DC) and the pulsed current mode to investigate whether the two techniques would lead to a difference in the corrosion behavior of the plated films. The range of deposition current density was obtained through a systematic cyclic voltammetry (CV). The chosen current density values were − 50, − 150, − 180, and − 250 mA/cm2. Pulse deposition was done after the DC deposition at the average current density of − 180 mA/cm2 at different duty cycles, frequencies and peak current densities. The thickness of the coating was measured by using a surface profilometer and was found to be in the range of 10–28 µm. Phase, structure and composition of the deposition were characterized by XRD, SEM and elemental mapping. Tafel polarization technique and electrochemical impedance spectroscopy were done to study the corrosion rate and mechanism in 3.5 wt% NaCl. A marginal increase in corrosion resistance was observed for pulse-deposited films as compared to DC-deposited ones. Films deposited at − 180 mA/cm2 and a combination of duty cycle, i.e., peak current density of − 720 mA/cm2 and at the frequency of 75 Hz, were found to have the optimum anti-corrosion performance.

Similar content being viewed by others

References

Karthick S, Muralidharan S, and Saraswathy V, Arab J Chem 13 (2020) 3301. https://doi.org/10.1016/j.arabjc.2018.11.005

Shibli S M A, Meena B N, and Remya R, Surf Coat Technol 262 (2015) 210. https://doi.org/10.1016/j.surfcoat.2014.12.054

Asgari H, Toroghinejad M R, and Golozar M A, Curr Appl Phys 9 (2009) 59. https://doi.org/10.1016/j.cap.2007.10.090

Verma A R B, and Van Ooij W J, Surf Coat Technol 89 (1997) 132. https://doi.org/10.1016/S0257-8972(96)02941-6

Vasilakopoulos D, Bouroushian M, and Spyrellis N, Electrochim Acta 54 (2009) 2509. https://doi.org/10.1016/j.electacta.2008.11.059

Bengoa L N, Bruno S, Lazzarino H A, Seré P R, and Egli W A, Mater Sci 8 (2015) 1174. https://doi.org/10.1016/j.mspro.2015.04.183

Dattilo M, Cole E R, and O’Keefe T J, Conserv Recycl 9 (1986) 55. https://doi.org/10.1016/0361-3658(86)90134-7

Feng Z, Li Q, Zhang J, Yang P, and An M, Surf Coat Technol 270 (2015) 47. https://doi.org/10.1016/j.surfcoat.2015.03.020

Jyotheender K S, and Srivastava C, Metall Mater Trans A Phys Metall Mater Sci 52 (2021) 364. https://doi.org/10.1007/s11661-020-06070-y

Rekha M Y, and Srivastava C, Corros Sci 152 (2019) 234. https://doi.org/10.1016/j.corsci.2019.03.015

Sahayata B, Kumar S, Upadhyay P, Mendon R R, and Mallik A, Mater Lett 351 (2023) 135013. https://doi.org/10.1016/j.matlet.2023.135013

Fathy N, Kobayashi R, and Ichimura M, Mater Sci Eng B Solid-State Mater Adv Technol 107 (2004) 271. https://doi.org/10.1016/j.mseb.2003.11.021

Ataie S A, and Zakeri A, Surf Coat Technol 359 (2019) 206. https://doi.org/10.1016/j.surfcoat.2018.12.063

Doğan F, Uysal M, Duru E, Akbulut H, and Aslan S, J Asian Ceram Soc 8 (2020) 1271. https://doi.org/10.1080/21870764.2020.1840704

Ollendorf H, and Schneider D, Surf Coat Technol 113 (1999) 86. https://doi.org/10.1016/S0257-8972(98)00827-5

Kabir M S, Munroe P, Zhou Z, and Xie Z, Wear 380–381 (2017) 163. https://doi.org/10.1016/j.wear.2017.03.020

Sahu R K, Mukherjee D, Tiwari J P, Mishra T, and Pathak L C, J Mater Chem 19 (2009) 6810. https://doi.org/10.1039/b908080e

Ju H, Wu J, and Xu Y, J Chem Sci 125 (2013) 687. https://doi.org/10.1007/s12039-013-0407-9

Ayagou M D D, Tran T T M, Tribollet B, Kittel J, and Duret-Thual C, Electrochim Acta 282 (2018) 775. https://doi.org/10.1016/j.electacta.2018.06.052

Acknowledgements

The authors are thankful to Department of Metallurgical and Materials Engineering, National Institute of Technology Rourkela and Tata Steel Limited Jamshedpur for providing the equipment and financial facility.

Funding

The funding was supported by Tata Steel (Grant No: 3000132079/132).

Author information

Authors and Affiliations

Contributions

PU contributed to conceptualization, methodology, analysis, writing and draft preparation; AN provided methodology; AB contributed to conceptualization; AB performed data curation, formal analysis, and review and editing; SD performed data curation and formal analysis; AM contributed to supervision, funding acquisition, conceptualization, data curation, formal analysis, and writing— review and editing.

Ethics declarations

Conflict of interest

The authors claim that they have no apparent financial conflicts of interest or close personal connections that could have appeared to have an influence on the research described in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Upadhyay, P., Nag, A., Banerjee, A. et al. A Comparative Study of Pulse and DC Electroplating of Zn onto Mild Steel for Improved Corrosion Resistance. Trans Indian Inst Met 77, 1393–1405 (2024). https://doi.org/10.1007/s12666-023-03108-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03108-8