Abstract

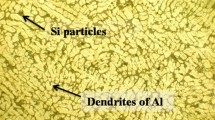

In this research, influence of boron carbide (B4C) particles on the corrosion behavior of magnesium metal matrix composite is examined. AZ31-B4C composites are fabricated through ultrasonic vibration-assisted stir casting process by reinforcing varying amount of boron carbide (0.5–2 wt.%) in AZ31 alloy. Characterizations of the composites are carried out using optical microscope , scanning electron microscope (SEM) and energy-dispersive spectroscope (EDS). The optical images show equiaxed orientation of grains in fabricated composites. SEM analysis confirms uniform distribution of reinforcement particles in composites. EDAX result confirms the inclusion of B4C particles in the Mg matrix. The microhardness of all composites and base alloy is measured using Vickers’s microhardness tester. Microhardness values are found to be increased with increase in wt.% of B4C nanoparticles. Electrochemical corrosion tests are carried out on AZ31-B4C metal matrix composites in 3.5% NaCl solution. AZ31-1B4C composite is found to be the most corrosion-resistant material among tested materials. Furthermore, corrosion morphology of samples is scrutinized under SEM and EDS.

Similar content being viewed by others

References

Alvarez R B, Martin H J, Horstemeyer M F, Chandler M Q, Williams N, Wang P T, and Ruiz A, Corros Sci 52 (2010) 1635. https://doi.org/10.1016/j.corsci.2010.01.018.

Kulekci M M, Int J Adv Manuf Technol 39 (2008) 851. https://doi.org/10.1007/s00170-007-1279-2.

Avedesian M M, and Baker H, Magnesium and Magnesium Alloys, ASM International, 1999, ASM Speciality Handbook. ISBN: 978–0–87170–657–7.

Makar G L, and Kruger J, Int Mater Rev 38 (1993) 138. https://doi.org/10.1179/imr.1993.38.3.138.

Esmaily M, Svensson JE, Fajardo S, Birbilis N, Frankel GS, Virtanen S, and Johansson LG, Progress Mater Sci 89 (2017) 92. https://doi.org/10.1016/j.pmatsci.2017.04.011.

Endo M, Hayashi T, Itoh I, Kim Y A, Shimamoto D, Muramatsu H, and Koide S, Appl Phys Lett 92 (2008) 063105. https://doi.org/10.1063/1.2842411.

Titarmare V, Banerjee S, and Sahoo P, Mater Today: Proc (2021). https://doi.org/10.1016/j.matpr.2021.10.373.

Esmaily M, Mortazavi N, Svensson J E, Halvarsson M, Jarfors, A E, Wessén M, Arrabal R, and Johansson L G, Mater Chem Phys 180 (2016) 29. https://doi.org/10.1016/j.matchemphys.2016.05.016.

Chandrashekar A, Mohanavel V, Kaladgin A R, Kumar V, Ravichandran M, Arunkumar G L, and Basheer D, Surf Topogr Metrol Prop 9 (2021) 045046. https://doi.org/10.1088/2051-672x/ac41ff.

Rahmani K, Majzoobi G H, Bakhtiari H, and Sadooghi A, Mater Chem Phys 271 (2021) 124946. https://doi.org/10.1016/j.matchemphys.2021.124946.

Falcon L A, Bedolla B E, Lemus J, Leon C, Rosales I, and Gonzalez-Rodriguez J G, Int J Corros 2011 (2011) 896845. https://doi.org/10.1155/2011/896845.

Mindivan H, Efe A, Kosatepe A H, and Kayali E S, Appl Surf Sci 318 (2014) 234. https://doi.org/10.1016/j.apsusc.2014.04.127.

Raghav G R, Balaji, A N, Muthukrishnan D, Sruthi V, and Sajith E, Mater Res Express 5 (2018) 066523. https://doi.org/10.1088/2053-9591/aac862.

Banerjee S, Sahoo P, and Davim J P, Adv Mech Eng, 13(2021) 16878140211009025. https://doi.org/10.1177/16878140211009025.

Prema C E, Suresh S, Ramanan G, and Sivaraj M, Mater Res Express 7 (2020) 016524. https://doi.org/10.1088/2053-1591/ab6257.

Toptan F, Rego A, Alves A C, and Guedes A, J Mech Behav Biomed Mater 152-163 (2016) 61. https://doi.org/10.1016/j.jmbbm.2016.01.024.

Casati R, and Vedani M, Metals 4 (2014) 65. https://doi.org/10.3390/met4010065.

Tiwari S, Balasubramaniam R, and Gupta M, Corros Sci, 49 (2007) 711. https://doi.org/10.1016/j.corsci.2006.05.047.

Turan M E, Sun Y, Akgul Y, Turen Y, and Ahlatci H, J Alloy Compd 724 (2017) 14. https://doi.org/10.1016/j.jallcom.2017.07.022.

Hihara L H, and Kondepudi P K, Corros Sci 34 (1993) 1761. https://doi.org/10.1016/0010-938X(93)90014-8.

Nunez-Lopez C A, Skeldon P, Thompson G E, Lyon P, Karimzadeh H, and Wilks T E, Corros Sci, 37 (1995) 689. https://doi.org/10.1016/0010-938X(95)80003-4.

Zucchi F, Trabanelli G, Grassi V, and Frignani A, Corrosion 60 (2004), 362. https://doi.org/10.5006/1.3287744.

Chan W M, Cheng F T, Leung L K, Horylev R J and Yue T M, Corrosion behavior of magnesium alloy AZ91 and its MMC in NaCl solution. In Corrosion97. NACE-97441. (1997) https://doi.org/10.1007/s00339-017-1118-8.

Nunez-Lopez C A, Habazaki H, Skeldon P, Thompson G E, Karimzadeh H, Lyon P, and Wilks TE, Corros Sci 38 (1996)1721. https://doi.org/10.1016/S0010-938X(96)00068-6.

Ma X L, Dong L H, and Wang X, Mater Des 305-312 (2014) 56. https://doi.org/10.1016/j.matdes.2013.11.041.

Banerjee S, Poria S, Sutradhar G, and Sahoo P, J Magnes Alloy 7 (2019) 681. https://doi.org/10.1016/j.jma.2019.07.004.

Pardo A, Merino M, Coy A E, Viejo F, Arrabal R, and Feliú Jr S, Electrochim Acta 53 (2008) 7890. https://doi.org/10.1016/j.electacta.2008.06.001.

Endo M, Hayashi T, Itoh I, Kim Y A, Shimamoto D, Muramatsu H, Shimizu Y, Morimoto S, Terrones M, Iinou S, and Koide S, Appl Phys Lett 92 (2008) 063105. https://doi.org/10.1063/1.2842411.

Ganguly S, Mondal A K, Sarkar S, Basu A, Kumar S, and Blawert C, Corros Sci 166 (2020) 108444. https://doi.org/10.1016/j.corsci.2020.108444.

Banerjee S, Poria S, Sutradhar G, and Sahoo P, IInt J Metal Cast 15 (2021) 1058. https://doi.org/10.1007/s40962-020-00538-8.

Rashad M, Pan F, Asif M, and Chen X, J Magnes Alloy 5 (2017) 271. https://doi.org/10.1016/j.jma.2017.06.003.

Turhan M C, Li Q, Jha H, Singer R F, and Virtanen S, Electrochim Acta 56 (2011) 7141. https://doi.org/10.1016/j.electacta.2011.05.082.

Pathak S S, Blanton M D, Mendon S K, and Rawlins J W, Corros Sci 52 (2010) 1453. https://doi.org/10.1016/j.corsci.2009.11.032.

Song G L, and Gannon P E, Magnesium Technology Springer, Cham (2016), pp 285-290. https://doi.org/10.1007/978-3-319-48114-2_56.

Turhan M C, Li Q, Jha H, Singer R F, and Virtanen S, Electrochim Acta 56 (2011) 7141. https://doi.org/10.1016/j.electacta.2011.05.082.

Thirumalaikumarasamy D, Shanmugam K, and Balasubramanian V, J Magnes Alloy 2 (2014) 36. https://doi.org/10.1016/j.jma.2014.01.004.

Wang Y, Wei M, Gao J, Hu J, and Zhang Y, Mater Lett 62 (2008) 2181. https://doi.org/10.1016/j.matlet.2007.11.045.

Bakhsheshi-Rad H R, Hamzah E, Tok H Y, Kasiri-Asgarani M, Jabbarzare S, and Medraj M, J Mater Eng Perform 26 (2017) 653. https://doi.org/10.1007/s11665-016-2499-0.

Kavimani V, Soorya Prakash K, and Arun Pandian M, Appl Phys A, 123 (2017) 1. https://doi.org/10.1007/s00339-017-1118-8.

Ascencio M, Pekguleryuz M, and Omanovic S, Corros Sci 87 (2014) 489. https://doi.org/10.1016/j.corsci.2014.07.015.

Banerjee S, Sarkar P, and Sahoo P, Improving corrosion resistance of magnesium nanocomposites by using electroless nickel coatings. Facta Universitatis, Series: Mechanical Engineering, (2021) Retrieved from http://casopisi.junis.ni.ac.rs/index.php/FUMechEng/article/view/7833.

Acknowledgements

This paper was presented in TRIBOINDIA2021 with Abstract ID TI21036.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Titarmare, V.P., Banerjee, S. & Sahoo, P. Corrosion Characteristics of AZ31-B4C Composites. Trans Indian Inst Met 76, 2445–2461 (2023). https://doi.org/10.1007/s12666-022-02709-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02709-z