Abstract

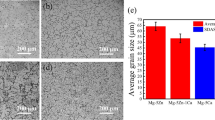

In this study, medical Mg–xZn (x = 3, 6, 9 wt%) alloys were successfully prepared by a novel technique, semi-solid powder moulding. The effects of Zn content and temperature (580, 590, 600 ℃) on the relative density, microstructure, microhardness and degradation behaviour were studied. The microstructure evolution and refinement mechanism during the forming process were analysed. The results show as the temperature and Zn content increase, the relative density and microhardness gradually increase. When the temperature is 600 ℃, the relative density of Mg–3Zn, Mg–6Zn and Mg–9Zn is 92.3%, 97.2% and 97.8%, respectively. The corresponding microhardness is 101.2 HV, 105.6 HV and 106.3 HV, respectively. The prepared Mg–Zn alloys have fine microstructure with equiaxed grains, which consists of α-Mg matrix and second phase of MgZn2 with a few of Mg4Zn7 and Mg2Zn11. As Zn content increases, the amount of second phase increases, and the microstructure becomes uneven at the Zn content of 9 wt%. Pseudo-transgranular liquation cracking is one of the grain refinement mechanisms. As the Zn content increases, the corrosion rate decreases firstly and then increases. Mg–6Zn prepared at 600 ℃ has the lowest corrosion rate of 4.8 mm/year after 9 days of dynamic immersion. Both the porosity and second phase influence the corrosion rate, but the porosity is the main factor controlling the degradation. Mg–6Zn alloy is the best composition based on the properties and microstructures. The main components of corrosion products are Mg (OH)2, hydroxyapatite and a small amount of MgO and CaCO3, which shows a good biocompatibility. Semi-solid powder moulding shows a fantastic potential to prepare medical Mg alloys.

Similar content being viewed by others

References

Witte F, Kaese V, Haferkamp H, Switzer E, Meyer-Lindenberg A, Wirth C J, and Windhagen H, Biomaterials 26 (2005) 3557

Duygulu O, Alper Kaya R, Oktay G, and Arslan Kaya A, Sci. Forum 546 (2007) 421

Wang J, Liu L, Wu Y, Maitz M F, Wang Z, Koo Y, Zhao A, Sankar J, Kong D, Huang N, and Yun Y, Acta Biomater. 50 (2017) 546

Luo X, Ebel T, Pyczak F, Limberg W, and Lin Y, Mater. Lett. 193 (2017) 295

Pereda M D, Alonso C, Burgos-Asperilla L, Del Valle J A, Ruano O A, Perez P, and Fernández Lorenzo De Mele M A, Acta Biomater. 6 (2010) 1772

Zheng Y F, Gu X N, Xi Y L, and Chai D L, Acta Biomater. 6 (2010) 1783

Yu J, Wang J, Li Q, Shang J, Cao J, and Sun X, Rare Met. Mater. Eng. 45 (2016) 2757

Wolff M, Mesterknecht T, Bals A, Ebel T, and Willumeit-Römer R, Miner. Met. Mater. Ser. 2019 (2019) 43

Luo X, Fang C, Fan Z, Huang B, and Yang J, Mater. Res. Express 6 (2019) 076528

Wu Y, Gap-Yong Kim M P, Russell A, Anderson I, Shrotriya P, and Wang X, Mech. Eng. (2011)

Czerwinski F, Int. J. Cast Met. Res. 33 (2020) 1571

Czerwinski F, Mater. Sci. Technol. (UK) 35 (2019) 999

Czerwinski F, Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 49 (2018) 3220

Luo X, Wu M, Fang C, and Huang B, JOM 71 (2019) 4349

Verissimo N C, Freitas E S, Cheung N, GarciaA, and Osório W R, J. Alloys Compd. 723 (2017) 649

Luo X, Fang C, Yao F, Zhao H, and Yan S, Trans. Indian Inst. Met. 72 (2019) 1791

Zhang S, Zhang X, Zhao C, Li J, Song Y, Xie C, Tao H, Zhang Y, He Y, Jiang Y, and Bian Y, Acta Biomater. 6 (2010) 626

Li X. Study on Diffusion Propertiesof Ca, Zn, Al in Mg, Ph D Thesis Chongqing University Master Thesis (in Chinese) (2015)

Liu Y, Luo X, and Li Z, J. Mater. Process. Technol. 214 (2014) 165

Luo X, Liu Y, Mo Z, and Gu C, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. (2015)

Luo X, Liu Y, Gu C, and Li Z, Powder Technol. 261 (2014) 161

Karagadde S, Lee P D, Cai B, Fife J L, Azeem M A, Kareh K M, Puncreobutr C, Tsivoulas D, Connolley T, and Atwood R C, Nat. Commun. 6 (2015) 8300

Gui Z Z, Researches on Design, Preparation and Properties of Biomedical Degradable Mg-RE Alloys, Ph D Thesis, South China University of Technology (in Chinese) (2018)

Shi Z, Liu M, and Atrens A, Corros. Sci. 2 (2010) 579

Eshwara P S N, Diana K, Berit Z-P, Domonkos T, Bjorn W, Frank F, Thomas E, and Regine W-R, J. Magnes. Alloy, 9 (2021) 686

Wu L, He Y H, Jiang Y, Zeng Y, Xiao Y F, Nan B, Trans. Nonferrous Met. Soc. China, 24 (2014) 3509

Mohamed A, El-Aziz A M, and Breitinger H G, J. Magnes. Alloy. 7 (2019) 249

Cui Z Q, Li W J, Cheng L X, Gong D Q, Cheng W L, and Wang W X. Mater Charact. 151 (2019) 620

Du W, Liu K, Ma K, Wang Z, and Li S, J. Magnes. Alloy. 6 (2018) 1

Luo X, Liu Y Z, and Wang B, Acta Metall. Sin. (English Lett). 28 (2015) 1305

Acknowledgements

The authors gratefully acknowledge the financial support of National Natural Science Foundation of China (No. 51704255) and Sichuan Science and Technology Program (No. 2020YFH0151).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, X., Yang, S., Li, M. et al. The Properties Evolution of Medical Mg–Zn Alloys Prepared by Semi-solid Powder Moulding. Trans Indian Inst Met 74, 3063–3073 (2021). https://doi.org/10.1007/s12666-021-02373-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02373-9