Abstract

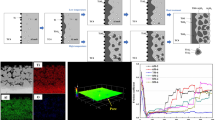

This study examined the applicability of the hot-dipping aluminizing technique carried out on commercially pure titanium (Ti) as a new method for the formation of Ti-aluminides on a Ti surface. The process was carried out using pure aluminum (Al) and Al 7075 alloy in molten Al baths at 900 °C and 1000 °C for 4 h and 6 h, respectively. The microstructure, phase fraction, and composition analysis of the formed layers were examined using field emission scanning electron microscopy, energy-dispersive spectroscopy, and X-ray diffraction. Three different areas with different thicknesses were formed on the Ti surface by the hot-dipping aluminizing technique. The top (Al coating) layer consisted of Ti and Al elements having a higher hardness than the base metal. The second layer, formed below the Al coating, was the Ti–Al layer having the highest hardness on the surface. Below this layer the Al was diffused. As a result of the Ti aluminizing process carried out at different temperatures and durations in this study, TiAl, TiAl2, TiAl3, and Ti3Al phases were obtained. These phases positively affected the mechanical and corrosion properties.

Similar content being viewed by others

References

Kaplan Y, Can A C, Ulukoy A, P I Mech Eng. L-J Mat233 (2019) 109.

Viteri V S, Elena F, Titanium and titanium alloys as biomaterials, Rijeka: Intech, (2013), p 160.

Fenghua L, Xiaohong Y, Jinglei Z, Zhanguo F, Dianting G, Zhengping X, Acta Metall Sin23, (2010), 293.

Ataibis V, Taktak S, Surf Coat Tech 279 (2015) 65.

Donachie, M J, Titanium: a technical guide. Materials Park, OH: ASM International (2000), p 65.

Boyer R R, Adv Perform Mater2 (1995) 349.

Ranjan S, Mukherjee B, Islam A, Pandey K K, Gupta R, Keshri A K, J Eur Ceram Soc40 (2020) 660.

Sienkiewicz J, Kuroda S, Murakami H, Araki H, Giżyński M, Kurzydłowski K J, J Therm Spray Techn28 (2019) 563.

Swadźba R, Swadźba L, Mendala B, Witala B, Tracz J, Marugi K, Intermetallics87 (2017) 81.

Choi K, Song Y, Yi S, Park J S, Korean J Met Mater57 (2019) 131.

Fan X, Darut G, Planche M P, Feng X, Liao H, Montavon G, J Therm Spray Techn28 (2019) 265.

Esmaeili M M, Mahmoodi M, Imani R, Int J Appl Ceram Tec14 (2017) 374.

Cammarota G P, Casagrande A, Sambogna G. Surf Coat Tech201 (2006) 230.

Abro M A, Hahn J, Lee D B, Met Mater Int24 (2018) 507.

Abro M A, Lee D B, Met Mater Int23 (2017) 92.

Kim M J, Lee D B, Korean J Met Mater53 (2015) 406.

Cheng W J, Wang C J, App. Surf Sci257 (2011) 4663.

Wang C J, Badaruddin M, Surf Coat Tech205 (2010) 1200.

Eaton D C G, Advanced Materials for Lightweight Structures, in: Proceedings of the ESA International Symposium, ESA SP–339.

Nouri S, Rastegari S, Mirdamadi S, Hadavi M, Trans Indian Inst Met68 (2015) 867.

Kothari K, Radhakrishnan R, Wereley N M, Prog Aerosp Sci55 (2012) 1.

Cahn R W, Haasen P, Physical Metallurgy, 4th edt. Elsevier, Amsterdam, (1996).

Whang S H, Pope D P, Liu C T, High temperature aluminides and intermetallics, in: Proceedings of the 2nd ASM Conference on HTAAI, Elsevier, Amsterdam, (1993).

Medda E, Delogu F, Cao G. Mat Sci Eng A361 (2003) 23.

Gupta RK, Pant B, Sinha P P, Trans Indian Inst Met67 (2014) 143.

Jiang W, Fan Z, Li G, Liu X, Liu F, J Alloy Compd 688 (2016) 742.

Rastkar A R, Parseh P, Darvishnia N, Hadavi S M M, Appl Surf Sci 276 (2013) 112.

Haftlang F, Habibolahzadeh A, Sohi M H, App. Surf Sci 329 (2015) 240.

Kim J H, Wang J P, Kang C Y, Met Mater Int 17 (2011) 931.

Khoshhal R, Met Mater Int25 (2019), 449.

Sujata M, Bhargava S, Sangal S J, J Mater Sci Let,1 (1997) 1175.

Kattner U R, Lin J C, Chang Y A, Metall Trans A23 (1992) 2081.

Sujata M, Bhargava S, Sanga S, ISIJ Int,36 (1996) 255.

Loo F J, Rieck G D, Acta Metall21 (1973) 73.

Sprengel W, Nakajima H, Oikawa H, Mat Sci Eng A213 (1996) 45.

Loiseau A, Vannuffel C, Phys Status Solidi A107 (1988) 655.

Mizuta N, Matsuura K, Kirihara S, Miyamoto Y, Mat Sci Eng A492 (2008) 199.

Jianing L, Chuanzhong C, Lei Z, Int. J. of Refract. Met H29 (2011) 49.

Li S, Ling-Yan K, Tian-ying X, Hao D, Tie-fan L, Trans Nonferrous Met Soc China19, (2009) 879.

Udayashankar N K, Rajasekaran S, Nayak J, Trans. Indian Inst. Met.61 (2008) 231.

Jianing L, Chuanzhong C, Zhaoqing L, Squartini T, J Alloy Compd509 (2011) 4882.

Venkataraman B, Sundararajan G, Wear245 (2000) 22.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aksöz, S., Kaplan, Y. Formation of Ti-Aluminides on Commercially Pure Ti via the Hot-Dipping Aluminizing Process. Trans Indian Inst Met 73, 1065–1072 (2020). https://doi.org/10.1007/s12666-020-01948-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01948-2