Abstract

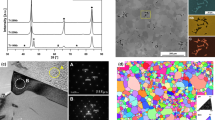

Active brazing is a commonly used method for joining ceramic materials. In the present study, the wetting behavior of four Ti-rich ternary Ni–Ti–Zr alloys was investigated through sessile drop experiments on alumina disks of 96 and 99.9 % purity. The microstructure at the metal/alumina interface was analyzed using scanning electron microscopy and energy-dispersive X-ray spectroscopy. Three of the analyzed alloys exhibited reactive wetting with final contact angles between 40° and 70°. The reaction phases at the metal/alumina interface had a thickness of about 1 µm and were of a similar composition for all alloys. Dilatometer measurements showed thermal expansion coefficients between 13.2 and 15.8 × 10−6 °C−1. The lowest wetting angle of 40° was achieved with the alloy 61Ti–20Zr–19Ni at temperatures above 980 °C.

Similar content being viewed by others

References

Nicholas MG (ed) (1990) Joining of ceramics. Chapman and Hall, London

Eustathopoulos N (2005) Progress in understanding and modeling reactive wetting of metals on ceramics. Curr Opin Solid State Mater Sci 9(4–5):152–160

Eustathopoulos N (1998) Dynamics of wetting in reactive metal ceramic systems. Acta Mater 46(7):2319–2327

Saiz E, Tomsia AP (2005) Kinetics of high-temperature spreading. Curr Opin Solid State Mater Sci 9(4–5):167–173

Saiz E, Cannon RM, Tomsia AP (2000) Reactive spreading: adsorption, ridging and compound formation. Acta Mater 48(18–19):4449–4462

Gomez-Garcia D, Gutierrez-Mora F, Gallardo-Lopez A, Dominguez-Rodriguez A (2007) A general law for liquid metal-onto-ceramic wetting: an electrostatic approach. J Eur Ceram Soc 27(11):3307–3310

Akselsen OM (1992) Advances in brazing of ceramics. J Mater Sci 27(8):1989–2000. doi:10.1007/BF01117909

Kumar G, Prabhu KN (2007) Review of non-reactive and reactive wetting of liquids on surfaces. Adv Colloid Interface Sci 133(2):61–89

Schwartz Mel M (1990) Ceramic joining. ASM International, London

Naidich YV, Zhuravlev VS, Gab II, Kostyuk BD, Krasovskyy VP, Adamovskyy AA, Taranets NY (2008) Liquid metal wettability and advanced ceramic brazing. J Eur Ceram Soc 28(4):717–728

Gupta KP (1999) The Ni–Ti–Zr system (nickel–titanium–zirconium). J Ph Equilib 20(4):441–448

Martienssen W, Warlimont H (2005) Springer handbook of condensed matter and materials data. Springer, Berlin

Meier A, Chidambaram PR, Edwards GR (1995) Generation of isothermal spreading data for liquid reactive metals on ceramic substrates: the copper–titanium/alumina system. J Mater Sci 30:3791–3798. doi:10.1007/BF01153936

Davis JP, Majzoub EN, Simmons JM, Kelton KF (2000) Ternary phase diagram studies in Ti–Zr–Ni alloys. Mat Sci Eng A 294:104–107

Wu M, Cao CZ, Rafi ud din, He XB, XH Qu (2013) Brazing diamond/Cu composite to alumina using reactive Ag–Cu–Ti alloy. Trans Nonferr Met Soc China 23(6):1701–1708

Voytovych R, Robaut F, Eustathopoulos N (2006) The relation between wetting and interfacial chemistry in the CuAgTi/alumina system. Acta Mater 54(8):2205–2214

Hosking FM et al (2000) Microstructural and mechanical characterization of actively brazed alumina tensile specimens. Weld J Res Suppl 79(8):222–230

Lin C, Chen R, Shiue R (2001) A wettability study of Cu/Sn/Ti active braze alloys on alumina. J Mater Sci 36(9):2145–2150. doi:10.1023/A:1017531730604

Jasim KM et al (2010) Actively brazed alumina to alumina joints using CuTi, CuZr and eutectic AgCuTi filler alloys. Ceram Int 36(8):2287–2295

Shiue RK, Wu SK, O JM, Wang JY (2000) Microstructural evolution at the bonding interface during the early-stage infrared active brazing of alumina. Metall Mater Trans A 31(10):2527–2536

Halbig MC, Coddington BP, Asthana R, Singh M (2013) Characterization of silicon carbide joints fabricated using SiC particulate-reinforced Ag–Cu–Ti alloys. Ceram Int 39(4):4151–4162

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siegmund, P., Guhl, C., Schmidt, E. et al. Reactive wetting of alumina by Ti-rich Ni–Ti–Zr alloys. J Mater Sci 51, 3693–3700 (2016). https://doi.org/10.1007/s10853-015-9684-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9684-7