Abstract

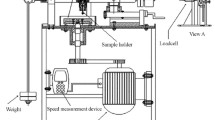

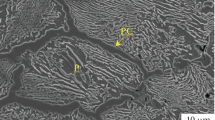

In this study, dry sliding wear behaviors of 17-4 PH stainless steel (SS) alloys fabricated by powder metallurgy were investigated. Alloys containing different amounts of Ta were aged at 480 °C for three different times. After the aging treatment, the alloys were characterized with scanning electron microscope, X-ray diffraction, density, and hardness. The parameters of the wear tests were 0.8 ms−1 sliding speed, 30 and 45 N load, and five various sliding distances (600–3000 m). As a result of the study, it was found that the alloys produced by powder metallurgy had ferritic microstructures. Density and hardness values of 17-4 PH SS alloys containing various amounts of Ta were found to increase with increasing amount of Ta (after aging treatment). Also, microstructure examinations showed that M23C6 and M3C carbides were formed in the microstructure. The wear tests showed that the adhesive wear mechanism was the descent wear mechanism.

Similar content being viewed by others

References

Wang J, Zou H, Li C, Qiu S, and Shen B, Mater Charact59 (2008) 587.

Riazi H, Ashrafizadeh F, Hosseini S R, and Ghomashchi R, Mater Sci Eng A703 (2017) 262.

Jun W, Hong Z, Xiao-yong W, Cong L, Shao-yu Q, and Bao-luo S, Mater Trans, 46 (2005) 846.

Hsiao C, Chiou C, and Yang J, Mater Chem Phys74 (2002) 134.

Kochmanski P, and Nowacki J, Surf Coat Technol4834 (2008) 202.

Esfandiari H, and Dong M, Surf Coat Technol466 (2007) 202.

Wang J, Zou H, Li C, Qiu S, and Shen B, Mater Charact57 (2006) 274.

Nakagawa H, and Miyazaki T, J Mater Sci35 (2000) 2245.

Nalçacıoğlu E, Özyürek D, and Çetinkaya K, J Balk Tribol Assoc22-1 (2016) 261.

Kocmanski P, and Nowacki J, Surf Coat Technol202 (2008) 4834.

Xiao M, Li F, Xie H, and Wang Y, Mater Des34 (2012) 112.

Wu Y, Blaine D, Marx B, Schlaefer C, and German R M, J Mater Sci37 (2002) 2185.

Gulsoy H O, Scr Mater52 (2005) 187.

Gulsoy H O, Wear262 (2007) 491.

Cetinkaya C, Mater Des27 (2006) 437.

Kalyon A, Ozyurek D, Gunay M, and Aztekin H, High Temp Mater Processes34 (2015) 635.

Wu Y, German R M, Blain D, Marx B, and Schlaefer C, J Mater Sci37 (2002) 3573.

Wu Y, Blain D, Schlaefer C, Marx B, and German R M, Metall Mater Trans A33-7 (2002) 2185.

Salahinejad E, Hadianfard M J, Ghaffari M, and Mashhadi S B, Mater Lett74 (2012) 209.

Javanbakht M, Hadianfard M J, and Salahinejad E, J Alloys Compd624 (2015) 17.

Pandya S, Ramakrishna K S, Annamalai A R, and Upadhyaya A, Mater Sci Eng A556 (2012) 271.

Vencl A, Rac A, Bobic I, and Miskovic Z, Tribol Ind28 (1-2) (2006) 27.

Bressan J D, Daros D P, Sokolowski A, Mesquita R A, and Barbosa C A, J Mater Process Technol205 (2008) 353.

Ozyurek D, and Ciftci I, Sci Eng Compos Mater18 (2011) 5.

Saglam I, Ozyurek D, and Cetinkaya K, Bull Mater Sci34 (2011) 1465.

Ozyurek D, Ciftci I, and Tuncay T, Mater Test55 (2013) 468.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nalçacıoğlu, E., Ozyurek, D. & Çetinkaya, K. Influence of Ta Amount on Wear Performance of Aged 17-4 PH Stainless Steel Fabricated by Powder Metallurgy. Trans Indian Inst Met 72, 3081–3088 (2019). https://doi.org/10.1007/s12666-019-01774-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01774-1