Abstract

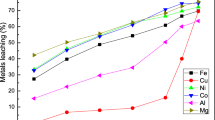

In the present paper, recovery of valuable metals from copper smelter slag of Balkhash copper plant (Kazakhstan) was investigated. To recover Fe, Zn and Cu to water-soluble form, the mixture of 150 g of copper slag and 60 g of 85% sulfuric acid was granulated and then roasted in the temperature range of 473–643 K (200–370 °C) followed by sulfuric acid leaching. Once the roasting temperature and duration are, respectively, 643 K (370 °C) and 150 min, the recovery% values of metals to water-soluble form reaches, accordingly: Fe—80.6, Zn—88.7, Cu—81.8. The resulting calcine was subjected to sulfuric acid leaching; after solid: liquid separation, a filtrate was obtained with the following composition, g/L: Fe2+—0.60; Zn2+—3.58; Cu2+—1.03. On adding ammonia water into the filtrate, 98% of iron was selectively precipitated, thereby separating from zinc and copper.

Similar content being viewed by others

References

Davenport W G, King M, Shlesinger M, and Biswas A K, Extractive Metallurgy of Copper, Elsevier Science Ltd., Oxford, UK, fourth ed., (2002).

Jadhav U U, and Hocheng H, JAMME 64 (2012) 159.

Sukla L B., Panda S C, and Jena P K Hydrometallurgy 16 (1986) 153.

Herreros O, Quiroz R, Manzano E, Bou C, and Vinals J, Hydrometallurgy 49 (1998) 87.

Banza A N, Gock E, and Kongolo K, Hydrometallurgy 67 (2002) 63.

Altundogan H S, and Tumen F, Hydrometallurgy 44 (1997) 261.

Altundogan H S, Boyrazli M,, and Tumen F, Miner Eng 17 (2004) 465.

Arslan C, and Arslan F, Hydrometallurgy 67 (2002) 1.

Carranza F, Iglesias N, Mazuelos A, Romero R, and Forcat O, Miner Eng 22 (2009) 107.

Kaksonen A H, Särkijärvi S, Puhakka J A, Peuraniemi E, Junnikkala S, and Tuovinen O H, Hydrometallurgy 159 (2016) 46.

Yang Z, Rui-lin M, Wang-dong N, and Hui W, Hydrometallurgy 103 (2010) 25.

Wang X, Geysen D, Padilla Tinoco S V, D’Hoker N, Van Gerven T, and Blanpain B, Miner Process Extr M 124 (2015) 83.

Nadirov R K, Syzdykova L I, Zhussupova A K, and Usserbaev M T, Int J Miner. Process 124 (2013) 145.

Muravyov M I, Bulaev A G, and Kondrat’eva T F, Miner Eng 64 (2014) 63.

Dimitrijevic M D, Urosevic D M, Jancovic Z D, and Milic S M, Physicochem Probl MI 52 (2016) 409.

Levenspiel O, Chemical Reaction Engieering, Wiley, New York, 2nd ed. (1972).

Levine R D, Molecular Reaction Dynamics, Cambridge University Press (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nadirov, R.K. Recovery of Valuable Metals from Copper Smelter Slag by Sulfation Roasting. Trans Indian Inst Met 72, 603–607 (2019). https://doi.org/10.1007/s12666-018-1507-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1507-5