Abstract

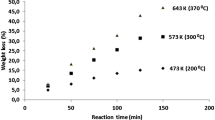

Copper smelting slag from Luanshya town in the Copperbelt province of Zambia contains significant amounts of elemental sulphur (about 37 weight %) which was dumped by the community. Leached tests with and without pre-treatment were carried out on the material. Direct leaching (without pre-treatment) yielded maximum recovery of about 26% for copper, while cobalt and chromium could not be extracted. Pre-treatment was done by roasting the material in air at a temperature range of 150–700 °C. The roasted calcine was leached at 33% solids and pH of 1.8. Copper leach efficiency of about 82% was obtained. The dissolution of cobalt and chromium during leaching was dependent on roasting temperature. Leach efficiency for cobalt and chromium decreased with increase in roasting temperature. It was concluded that high sulphur containing slag material should be processed via air roasting followed by leaching.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Piatak NM, Ettler V (2021) Introduction: metallurgical slags—environmental liability or valuable resource? In: Piatak NM, Ettler V (eds) Metallurgical slags: environmental geochemistry and resource potential. The Royal Society of Chemistry

Tümen F, Bailey NT (1990) Recovery of metal values from copper smelter slags by roasting with pyrite. Hydrometallurgy 25(3):317–328

Zhang C et al (2020) Recovery of valuable metals from copper slag. Min Metall Explor 37:1241–1251

Parirenyatwa S et al (2016) Comparative study of alkali roasting and leaching of chromite ores and titaniferous minerals. Hydrometallurgy 165:213–226

Tang J et al (2022) N6-methyladenosine (m6A) demethylase FTO regulates cellular apoptosis following cobalt-induced oxidative stress. Environ Pollut 297:118749

Keegan GM, Learmonth ID, Case C (2008) A systematic comparison of the actual, potential, and theoretical health effects of cobalt and chromium exposures from industry and surgical implants. Crit Rev Toxicol 38(8):645–674

Howie DW et al (1996) Biologic effects of cobalt chrome in cell and animal models. Clin Orthop Relat Res® 329:S217–S232

Kimbrough DE et al (1999) A critical assessment of chromium in the environment. Crit Rev Environ Sci Technol 29(1):1–46

Dotaniya M et al (2014) Chromium pollution: a threat to environment-a review. Agric Rev 35(2):153–157

Mitra S et al (2022) Impact of heavy metals on the environment and human health: novel therapeutic insights to counter the toxicity. J King Saud Univ-Sci 34(3):101865

Xu T et al (2019) Corrosion mechanisms of magnesia-chrome refractories in copper slag and concurrent formation of hexavalent chromium. J Alloy Compd 786:306–313

Namiluko YC et al (2023) Extraction of valuable metals from Luanshya copper smelting slag with minimal waste generation. In: TMS annual meeting & exhibition. Springer

Namiluko YC et al (2023) Processing of Luanshya copper smelting slag. In: TMS annual meeting & exhibition. Springer

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Namiluko, Y.C., Hara, Y.R.S., Shane, A., Chitewo, B., Hara, R., Parirenyatwa, S. (2024). Investigation of Roast-Leach of High Sulphur Containing Slag from Luanshya, Zambia. In: TMS 2024 153rd Annual Meeting & Exhibition Supplemental Proceedings. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50349-8_167

Download citation

DOI: https://doi.org/10.1007/978-3-031-50349-8_167

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50348-1

Online ISBN: 978-3-031-50349-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)