Abstract

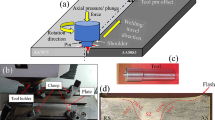

In this research work, dual-phase 600 steel grade and AA6082-T6 aluminum alloy dissimilar flat plates of thickness 2 mm were fabricated by using friction stir welding. Three tool rotational speeds of 560, 710 and 900 rpm, three tool traverse speeds of 24, 32 and 40 mm/min, three tool offsets of 0.8, 1.3 and 1.8 mm and constant tool tilt angle of 0.5° were used to obtain the defect-free welds. Macrostructure, microstructure evolutions, tensile strength, microhardness tests were carried out to assess the welding properties of dissimilar steel and aluminum welded joints. The highest tensile strength of 240 MPa with the joint efficiency of 85% of the base metal was obtained when the parameters were set to tool rotational speed of 710 rpm, traverse speed of 40 mm/min, tool tilt angle of 0.5° and tool pin offset of 1.3 mm using a tungsten carbide tool. The highest microhardness of 246 HV was obtained in the stir zone. Scanning electron microscopy was used to study the joint interface structure. The presence of Fe5Al8 and FeAl intermetallic compounds was confirmed by energy-dispersive X-ray and X-ray diffraction analysis.

Similar content being viewed by others

References

Cole G S and Sherman A M, Mater Charact 353 (1995) 9.

Meschut G, Janzen V, and Olfermann T, J Mater Eng Perform 23 (2014) 1515.

Sakiyama T, Murayama G, Naito Y, Saita K, Oikawa YMH, and Nose T, Nippon Steel Technical Report (2013).

Fekete J R and Hall J N, Processing and Applications, Automotive Steels, Woodhead Publishing (2017), p 1.

Xia M, Sreenivasan N, Lawson S, Zhou Y, and Tian Z, J Eng Mater Technol 129 (2007) 446.

Gopi S and Manonmani K, Aust J Mech Eng 11 (2013) 131.

Das H, Basak S, Das G, Pal TK, Int J Adv Manuf Technol 64 (2013) 53.

Thomas W M, Nicholas E D, Needham J C, Murch M G, Templesmith P, and Dawes C J, G.B. Patent Application No. 9125978.8 (1991).

Mishra R S and Ma Z Y, Materials Science and Engineering: R: Reports, Elsevier (2005).

Flores O V, Kennedy C, Murr L, Brown D, Pappu S, Nowak B M, and Mcclure J Scr Mater 38 (1998) 703.

Dilip J J S, Koilraj M, Sundareswaran V, Janakiram G D, and Koteswara Rao S R, Trans Indian Inst Met 63 (2010) 757.

Shuhuai X L and Ni J, Int JAdv manuf Technol 82 (2016) 2183.

Rafiei R, Ostavari Moghaddam A, Hatami M R, Khodabakshi F, Int J Adv Manuf Technol 90 (2016) 2785.

Ramachandran K K, Murugan N, and Shashi Kumar S, Mater Sci Eng A 639 (2015) 219.

Dehghani M, AMousavi S A A, and Amadeh A, Trans Nonferrous Met Soc China 23 (2013) 1957.

Uzun H, Dalle Donne C, Argagnotto A, Ghidini T, and Gambaro C, Mater Des 26 (2005) 41.

Watanabe T, Takayama H, and Yanagisawa A, J. Mater. Process. Technol. 178 (2006) 342.

Lee W-B, Schmuecker M, Mercardo U A, Biallas G, Jung S-B, Scr Mater 55 (2006) 355.

Derazkola H A, Aval H J, and Elyasi M, Sci Technol Weld Join 20 (2015) 553.

Jiang W H and Kovacevic R, Proc Inst Mech Eng B J Eng Manuf 218 (2004) 1323.

Kundu S, Roy D, Bhola R, Bhattacharjee D, Mishra B, and Chatterjee S, Mater Des 50 (2013) 370.

Yazdipour A and Heidarzadeh A, J Alloys Compd. 680 (2016) 595.

Swamy M M, Muthukumaran S, and Kiran K, Trans Indian Inst Met 70 (2017) 1221.

Sharma G and Dwivedi D K Trans Indian Inst Met 70 (2017) 201.

Chen T P and Lin W B, Sci Technol Weld Join 15 (2010) 279.

Aliasghar F, Ali S, Moghaddam O, and Amin A A, J Manuf Process 30 (2017) 418.

Moradi Faradonbeh A, Shamanian M, Edris H, Paidar M and Bozkurt Y J Mater Eng Perform 27(2018) 835.

ASTM E-8/E8M-11, Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, PA (2011).

Fukumoto S, Tsubakino H, Okita K, Aritashi M, and Tomita T, Mater Sci Technol 14 (1998) 33.

Nandan R, Debroy T, and Badheshia H K D H, Progr Mater Sci 53 (2008) 980.

Paul, R R, Martikainen J, and Suoranta R, Int J Mech Mater Eng 10 (2015) 26.

Liu X, Lan S, and Ni J Mater Des 59 (2014) 50.

Pantelis D I, Karakizis P N, Daniolos N M, Charitidis C A, Koumoulos E P, and Dragatogiannis D A, Mater Manuf Process 31 (2015) 264.

Arora A, Nandan R, Reynolds A P, and DebRoy T, Scr Mater 60 (2009) 13.

Arora A, Deb-Roy T, and Bhadeshia H K D H, Acta Mater 59 (2002) 2020.

Yilmaz M, Cöl M, and Acet M, Mater Charact 49 (2002) 421.

Mostafapour A, Jamalian H M, Bolghari A J, and Chamanara A, Int J Adv Manuf Technol 93 (2017) 3599.

Abnar B, Kazeminezhad M, and Kokabi A H, Trans Nonferr Met Soc China, 25 (2015) 2147.

Biallas G, Braun R, Donne C D, Staniek G, and Kaysser W A, First International Conference on Friction Stir Welds, Thousand Oaks, CA (1999).

Dragatogiannis D A, Koumoulos E P, Kartsonakis I, Pantelis D I, Karakizis P N, and Charitidis C A, Mater Manuf Process 31 (2015) 2101.

Rathod M and Kutsuna M, Weld J 83 (2004) 16.

Li X, Scherf A, Heilmaier M, and Stein F, J Phase Equilib Diffus 37 (2016) 162.

Sundman B, Ohnuma I, Dupin N, Kattner UR, and Fries SG Acta Mater. 57 (2009) 2896.

Haghshenas M, Abdel-Gwadb A, Omranb A M, Gökçec B, Sahraeinejada S, and Gerlicha A P, Mater Des 55 (2014) 442.

Akinlabi ET, J Mater Eng Perform 21 (2012) 1514.

Coelho R S, Kostka A, Santos J F, and Kaysser-pyzalla A, Mater Sci Eng A 556 (2012) 175.

Murugan B, Thirunavukarasu G, Kundu S, Kailash S V, and Chatterjee S, J Mater Eng Perform 27 (2018) 2921.

Darzi Naghibi H, Shakeri M and Hosseinzadeh M Trans Indian Inst Met 69 (2016) 891.

Meshram S D, Madhusudhan Reddy G, Defence Technol 11 (2015) 292.

Bang H, Bang H, Jeon G, Oh I, and Seung Ro C, Mater Des 37 (2012) 48.

Acknowledgements

Mr. Sameer MD, Research Scholar (Enrollment No. 16407002) under the guidance of Dr. Anil Kumar Birru, Assistant professor in Department of Mechanical Engineering, NIT Manipur, would also like to acknowledge the cooperation of Mr. Subhabrata Mukherjee, SSAB Europe, for his staunch support and providing dual-phase steel material and Fr. Rev Augustine Reddy Director, CJITS, for his support in carrying this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sameer, M.D., Birru, A.K. Investigations on Microstructural Evolutions and Mechanical Properties of Dual-Phase 600 Steel and AA6082-T6 Aluminum Alloy Dissimilar Joints Fabricated by Friction Stir Welding. Trans Indian Inst Met 72, 353–367 (2019). https://doi.org/10.1007/s12666-018-1487-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1487-5