Abstract

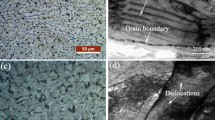

The microstructural and mechanical properties of structural steel (Hypoeutectoid steel) processed by equal channel angular pressing (ECAP), up to four passes, at room temperature with rounded 1200 channel angle ECAP pressing die was studied. The grain refinement and grain size distribution were analyzed using electron backscatter diffraction. Mechanical properties such as microhardness, yield strength, ultimate tensile strength, and strain hardening exponent were experimentally determined and correlated with the microstructure. With the increased number of ECAP passes, an improvement in strength was observed and ductility decreased due to work hardening. The change in morphology, such as grain refinement and increased high angle disorientation boundaries with dislocation density contribute to strengthening. TEM analysis confirmed the dislocation structure in deformed samples.

Similar content being viewed by others

References

Valiev R Z, and Langdon T G, Prog. Mater. Sci. 51 (2006) 881. https://doi.org/10.1016/j.pmatsci.2006.02.003.

Zhilyaev A P, Kim B K, Szpunar J A, Baro M D, and Langdon T G, Mater. Sci. Eng. A 391 (2005) 377. https://doi.org/10.1016/j.msea.2004.09.030

Lee K-M, and Lee H-C, J. Mater. Process. Technol. 210 (2010) 1574. http://dx.doi.org/10.1016/j.jmatprotec.2010.05.004.

Sun H Q, Shi Y-N, Zhang M-X, and Lu K, Acta Mater. 55 (2007) 975. https://doi.org/10.1016/j.actamat.2006.09.018.

Iwahashi Y, Horita Z, Nemoto M, and Langdon T G, Acta Mater. 46 (1998) 3317. https://doi.org/10.1016/s1359-6454(97)00494-1.

Gubicza J, Chinh N Q, Csanádi T, Langdon T G, and Ungar T, Mater. Sci. Eng. A. 462 (2007) 86. https://doi.org/10.1016/j.msea.2006.02.455.

Valiev R Z, Ivanisenko Y V, Rauch E F, and Baudelet B, Acta Mater. 44 (1996) 4705. https://doi.org/10.1016/s1359-6454(96)00156-5.

Rybal chenko O V, Dobatkin S V, Kaputkina L M, Raab G I, and Krasilnikov N A, Mater. Sci. Eng. A 387 (2004) 244. https://doi.org/10.1016/j.msea.2004.03.097.

Mishra A, Richard V, Grégori F, Asaro R J, and Meyers M A, Mater. Sci. Eng. A. 410–411 (2005) 290. https://doi.org/10.1016/j.msea.2005.08.201.

Astafurova E G, Zakharova G G, Naydenkin E V, Raab G I, and Dobatkin S V, Phys. Mesomech. 14 (2011) 195. https://doi.org/10.1016/j.physme.2011.08.011.

Zhao Y, Guo H, Fu M W, Ning Y, and Yao Z, Mater. Des. 46 (2013) 889. https://doi.org/10.1016/j.matdes.2012.11.047.

Shin D H, and Park K-T, Mater. Sci. Eng. A 410–411 (2005) 299. https://doi.org/10.1016/j.msea.2005.08.025.

Sabbaghianrad S, and Langdon T G, Mater. Sci. Eng. A. 596 (2014) 52. https://doi.org/10.1016/j.msea.2013.12.034.

Jahadi R, Sedighi M, Jahed H, Mater. Sci. Eng. A 593 (2014) 178. https://doi.org/10.1016/j.msea.2013.11.042.

Huang C X, Yang G, Gao Y L, Wu S D, and Zhang Z F, Mater. Sci. Eng. A. 485 (2008) 643. https://doi.org/10.1016/j.msea.2007.08.067.

Xu C, Furukawa M, Horita Z, and Langdon T G, Mater. Sci. Eng. A 398 (2005) 66. https://doi.org/10.1016/j.msea.2005.03.083

Shin D H, Kim I, Kim J, and Park K-T, Acta Mater. 49 (2001) 1285–1292. https://doi.org/10.1016/s1359-6454(01)10.

Astafurova E G, Zakharova G G, Naydenkin E V, Dobatkin S V, and Raab G I, Phys. Met. Metallogr. 110 (2010) 260. https://doi.org/10.1134/s0031918x10090097.

Fukuda Y, Oh-Ishi K, Horita Z, and Langdon T G, Acta Mater. 50 (2002) 1359. https://doi.org/10.1016/s1359-6454(01)00441-4.

Hazra S S, Pereloma E V, and Gazder A A, Acta Mater. 59 (2011) 4015. https://doi.org/10.1016/j.actamat.2011.03.026.

Gazder A A, Cao W, Davies C H J, and Pereloma E V, Mater. Sci. Eng. A 497 (2008) 341. https://doi.org/10.1016/j.msea.2008.07.030.

Ivanov A M, and Lukin E S, Mater. Sci. Eng. A 503 (2009) 45. https://doi.org/10.1016/j.msea.2008.02.054.

Park H-W, and J. Yanagimoto, Procedia Eng. 81 (2014) 462. https://doi.org/10.1016/j.proeng.2014.10.023.

Gubicza J, Chinh N Q, Krallics G, Schiller I, and Ungar T, Curr. Appl. Phys. 6 (2006)194. https://doi.org/10.1016/j.cap.2005.07.039.

Qu S, Huang C X, Gao Y L, Yang G, Wu S D, Zang Q S, and Zang Z F, Mater. Sci. Eng. A 475 (2008) 207. https://doi.org/10.1016/j.msea.2007.04.111.

Czarkowski P, Krawczynska A T, Slesinski R, Brynk T, Budniak J, Lewandowska M, and Kurzydlowski K J, Fusion Eng. Des. 86 (2011) 2517. https://doi.org/10.1016/j.fusengdes.2010.12.067.

Ding R, Tang D, Zhao A, Guo H, He J, and Zhi C, Mater. Des. 87 (2015) 649. https://doi.org/10.1016/j.matdes.2015.08.073.

Acknowledgements

The authors are thankful to the Director, National Institute of Technology, Tiruchirappalli (NITT) for providing the Sophisticated Instrumentation Facility (SIF) for carrying out this research investigation. The authors additionally acknowledge Prof. Indradev S. Samajdar, Head, National Facility for Orientation Image Microscopy, Indian Institute of Technology Bombay, India for EBSD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nagaraj, M., Ravisankar, B. Effect of Severe Plastic Deformation on Microstructural and Mechanical Properties of Structural Steel IS2062. Trans Indian Inst Met 71, 2315–2323 (2018). https://doi.org/10.1007/s12666-018-1363-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1363-3