Abstract

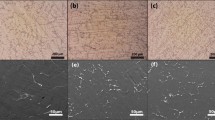

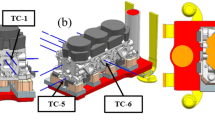

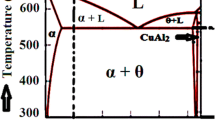

In this study, an attempt has been made to produce Al–10Cu–Fe alloy by vertical centrifugal casting at speeds ranging from 800 to 2850 rpm. The microstructural features, mechanical and wear properties have been investigated. The microstructure of Al–10Cu–Fe alloy consists of equiaxed grain morphology of the primary α-phase with eutectic phases in the interdendritic regions. It has been observed that there is a variation in the grain size from the inner surface of the casting to its outer surface. The speed also has a strong influence on the grain size and subsequent mechanical properties of the alloy. The wear properties of the alloy have been evaluated at a constant sliding velocity of 1 m/s for a range of applied load and sliding distance. The variations in the wear behavior are attributed to the size and solidification morphology of the castings.

Similar content being viewed by others

References

Kearney A, and Elwin L Rooy, “Alloy systems:Introduction to Aluminium and Aluminium Alloy”, in ASM Hand book vol. 2, properties and selection: Non ferrous Alloys and special-purpose materials, ASM International (1990).

Juneja J L, Studies on Centrifugal Casting of High Speed Steel, Ph. D. Thesis, IIT, Mumbai (1986).

Rajan T P D, Pillai R M, and Pai B C, Indian Foundry J 53 (2007) 79.

Rajan T P D, Pillai R M, and Pai B C, Int J Cast Met Res 21 (2008) 214.

Rajan T P D, and Pai B C, Trans Indian Inst Metals 62 (2009) 383.

Rajan T P D, Jaykumar E, and Pai B C, Trans Indian Inst Metals 65 (2012) 531.

Huang X, Liu C, Lu X, Liu G, and Li F, J Mater Process Technol 211 (2011) 1540.

Yong X, Liu C, and Zhai Y, J Rare Earth 28 (2009) 405.

Basak P S, Ray B C, and Chakrabarty I, J Mater Sci Lett 10 (1991) 313.

Halvaee A, and Talebi A, J Mater Process Technol 118 (2001) 123.

Ray B C, Mohanty U K, and Verma B B, Trans Indian Inst Metals 59 (2006) 57.

Chirita G, Soares D, and Silva F S, Mater Design 29 (2008) 20.

Mukunda P G, Shailesh Rao A, and Shrikantha Rao S, Front Mater Sci China 3 (2009) 339.

Mukunda P G, Shailesh Rao A, and Shrikantha Rao S, Met Mater Int 16 (2010) 137.

Shailesh Rao A, Mukunda P G, Shrikantha Rao S, and Sudhakar K G JOM 63 (2011) 25.

Sankara Rao L, Jha A K, and Ojha S N, J Mater Eng Perform 26 (2016) 601.

Pramila Bai B N, and Biswas S K, Acta Metall Mater 39 (1991) 833.

Pramila Bai B N, and Biswas S K, Wear 87 (1983) 237.

Reddy A S, Pramila Bai B N, Murthy K S S, and Biswas S K, Wear 181–183 (1995) 658.

Wilson S, and Alpas A T, Wear 225–229 (1999) 440.

Spurr R T, Wear 55 (1979) 289.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sankara Rao, L., Raju, K., Jha, A.K. et al. Microstructural and Tribological Characteristics of Al–10Cu–Fe alloy Produced by Vertical Centrifugal Casting process. Trans Indian Inst Met 71, 1427–1438 (2018). https://doi.org/10.1007/s12666-018-1276-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1276-1