Abstract

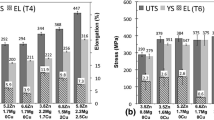

For complex structural castings, the microstructure and mechanical properties in different parts of the castings are affected by the structure, casting process, and the temperature change during the solidification process. In this study, the microstructure, filling process, and mechanical properties of Al-5Cu-0.38Mg-0.32Mn-0.1Ag alloy cylinder heads prepared by the sand gravity casting method were systematically investigated by optical microscopy (OM), scanning electron microscopy (SEM), electronic universal testing, and MAGMASOFT5.4. The cooling curves at typical positions of the cylinder heads were measured. Although the cooling rate was different for the cylinder heads in different positions, equiaxed grains could be found. Fine equiaxed grains with a size of 62 μm were found at the cylinder head fire surface, while coarse equiaxed grains with size of 116 μm could be observed at the cylinder head intake airway side wall. The yield strength and tensile strength of the cylinder heads at different positions were 140–159 MPa, and 175–202 MPa, respectively, and their elongation percentage was 2–4%. The cylinder head fire surface has the maximum yield strength of 159 MPa. In the process of tensile fracture of the as-cast alloy, micro-cracks were first generated along the eutectic structure at the grain boundary, and then these microcracks grew, aggregated with each other, and propagated along the grain boundary, resulting in the final fracture failure of the material.

Similar content being viewed by others

References

R.J. Ho and M.Z. Yusoff, K. Palanisamy, Trend and future of diesel engine: Development of high efficiency and low emission low temperature combustion diesel engine. IOP conference series. Earth and environmental science. 16: 12112. (2013)

M. Azadi, Int. J. Fatigue 99, 303 (2017).

D. Bakavos, P.B. Prangnell, B. Bes, and F. Eberl, Mater. Sci. Eng.: A 491(1–2), 214 (2008).

B.T. Sofyan, K. Raviprasad, and S.P. Ringer, Micron 32(8), 851 (2001).

J. Davis, ASM Specialty Handbook: Aluminum and Aluminum Alloys (ASM International, Materials Park, 1993).

D. Larouche and M. Javidani, Int. Mater. Rev. 59(3), 132 (2010).

B. Andilab, E. Vandersluis, P. Emadi, C. Ravindran, G. Byczynski, and R. Fernández-Gutiérrez, J. Mater. Eng. Perform. 31(7), 5679 (2022).

A. Girgis, M.H. Abdelaziz, A.M. Samuel, S. Valtierra, and F.H. Samuel, Metall. Microstruct. Anal. 8(5), 757 (2019).

A. Girgis, A.M. Samuel, H.W. Doty, S. Valtierra, and F.H. Samuel, Adv. Mater. Sci. Eng. 2019, 1 (2019).

G. Timelli, G. Camicia, and S. Ferraro, J. Mater. Eng. Perform. 23(2), 611 (2014).

L.A. Dobrzański, R. Maniara, and J.H. Sokolowski, Archiv. Mater. Sci. Eng. 106, 106 (2007).

S. Ashkvary, S.G. Shabestari, and F. Yavari, Int. J. Metalcast. 17(1), 322 (2023).

Y. Liu, R. Ding, Y. Han, Z. Gao, T. Ma, H. Wang, and Z. Ma, J. Mater. Sci. 58(13), 5921 (2023).

H. Mao, P. Lian, Y. Qi Wei, H.X. Wang, and Y. Li, J. Mater. Res. Technol. 26, 4784 (2023).

X. Liu, Q.L. Zhao, and Q.C. Jiang, Mater. Sci. Eng., A 790, 139737 (2020).

W. He, Y. Zhao, Q. Wei, H. Liu, D. Song, F. Shen, Z. Sun, and R. Li, J. Mater. Res. Technol. 27, 3655 (2023).

F. Mao, G. Yan, Z. Xuan, Z. Cao, and T. Wang, J. Alloys Compd. 650, 896 (2015).

H. Zhao, H. Bai, J. Wang, and S. Guan, Mater. Charact. 60(5), 377 (2009).

G. Ran, J. Zhou, and Q.G. Wang, J. Alloys Compd. 421(1–2), 80 (2006).

F.-Y. Xie, T. Kraft, Y. Zuo, C.-H. Moon, and Y.A. Chang, Acta Materialia 47(2), 489 (1999).

K. Kurz and D.J. Fisher, Fundamentals of Solidification, 4th edn. (Trans. Tech. Publications Ltd., Switzerland, 1998).

Author information

Authors and Affiliations

Contributions

Conceptualization, Data curation, Writing-original draft, CY and QW; writing-review and editing, LB and HX; investigation, data curation, HM and SL. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, C., Wang, Y., Wang, Q. et al. Effect of Cooling Rate on the Microstructure and Mechanical Properties of Al-5Cu-0.38Mg-0.32Mn-0.1Ag Alloy Cylinder Heads. JOM (2024). https://doi.org/10.1007/s11837-024-06384-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06384-x