Abstract

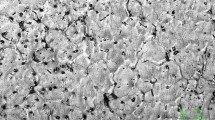

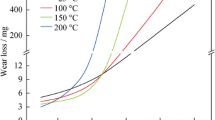

Dry sliding wear tests were performed on AZ31 alloy using a pin-on-disc configuration under the loads of 5–360 N and sliding speeds of 0.1–1.5 m/s. Friction and wear characteristics of AZ31 alloy were investigated as a function of the load and sliding speed. Wear mechanisms for AZ31 alloy were characterized by scanning electron microscopy. The wear behavior in mild and severe wear regimes was described in terms of plastic deformation and microstructure evolution in subsurface, and surface hardness change and temperature rise of worn surfaces. The results revealed that surface strain hardening caused by large plastic deformation played an important role in maintaining a low slope of wear rate in mild wear regime, while surface thermal softening originating from dynamic recrystallization and surface melting were responsible for a rapid wear in severe wear regime.

Similar content being viewed by others

References

Mordike B L, and Ebert T, Mater Sci Eng A 302 (2001) 37.

Avedesian M M, and Baker H, Magnesium and Magnesium Alloys-ASM Specialty Handbook, ASM International Materials Park (1999), p13.

Barnett M R, Keshavarz Z, and Beer A G, Acta Materilia 52 (2004) 5093.

Janik V, Yin D D, Wang Q D, He S M, Chen C J, Chen Z, and Boehlert C J, Mater Sci Eng A 528 (2011) 3105.

Kawamura Y, Hayashi K, Inoue A, and Masumoto T, Mater Trans JIM 42 (2001) 1172.

Inoue A, Matsusita M, Kawamura Y, Amiya K, Hayashi K, and Koike J, Mater Trans JIM 43 (2002) 580.

Habibnejad-Korayem M, Mahmudi R, Ghasemi H M, and Poole W J, Wear 268 (2010) 405.

Chen H and Alpas A T, Wear 246 (2000)106.

El-Morsy A-W, Mater Sci Eng A 473 (2008) 330.

Taltavull C, Torres B, Lopez A J, and Rams J, Wear 301 (2013) 615.

Paddar P, Das A, and Sahoo K L, Mater Des 54 (2014) 820.

Anbu selvan S, and Ramanthan S, Mater Des 31 (2010) 1930.

Jungk J M, Michael J R, and Pasad S V, Acta Materiallia 56 (2008) 1956.

Das S, Morale A T, and Alpas A T, Wear 268 (2010) 94.

Somekawa H, Meada S, Hirayama T, Mitsuoka T, Inoue T, and Mukai T, Mater Sci Eng A 561 (2013) 371.

Yao B, Han Z, and Lu K, Wear 294–295 (2012) 438.

Nguyen Q B, Sim Y H M, Gupta M, and Lim C Y H, Tribol Int (2014), doi:10.1016/triboint2014.02.024.

An J, Li R G, Lu Y, Chen C M, Xu Y, Chen X, and Wang L M, Wear 265 (2008) 97.

Wang S Q, Yang Z R, Zhao Y T, and Wei M X, Tribol Lett 38 (2010) 39.

Moore M A, and Douthwaite R M, Metall Trans A 7 (1976) 1833.

Tan J C, and Tan M J, Mater Sci Eng A 339 (2003) 124.

Mwembela A, Konopleva E B, and McQueen H J, Scripta Materialia 37 (1997) 1789.

Lim S C, and Ashby M F, Acta Metallurgica 35 (1987) 1.

Wonsiewicz B C, and Backofen W A, Trans Metall Soc AIME 239 (1967) 1422.

Yoshinaga H, and Horiuh R, Mater Trans JIM 4 (1963) 134.

Acknowledgments

The authors thank the Project 985-automotive engineering of Jilin University and National Foundation of Doctoral Station (Grant No.20110061110031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, C., Han, X., Su, T.F. et al. Roles of Friction-Induced Strain Hardening and Recrystallization in Dry Sliding Wear of AZ31 Magnesium Alloy. Trans Indian Inst Met 68, 89–98 (2015). https://doi.org/10.1007/s12666-014-0437-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-014-0437-0