Abstract

Forest plantations biomass is an interesting energy source for power generation with downdraft gasifier of less than 1 MW in Costa Rica. Thus, this work aims at evaluating the performance and efficiency of the electrical and thermal energy generation system in a downdraft gasifier with five woody biomass (Acacia mangium, Cupressus lusitanica, Gmelina arborea, Tectona grandis and Eucalyptus saligna). The biomass flow (10.9–13.5 kg/h) produced 18.1–22.5 kg/h of syngas flows. The ash production was 0.26–0.41 kg/h, and the biochar flow was 3.9–4.6 kg/h. The LHV of the syngas obtained was 5.77–6.77 MJ/Nm3, and the dry and tar free syngas composition was: 22.86–26.77% for CO, 4.08–5.74% for CH4, 14.56–17.61% for H2 and 10.19–13.49% for CO2. On the other hand, the electrical parameters showed a suitable performance for power generation, with 21.66–22.45 MJ/h, and an energy efficiency of 11.68- 14.25%. The motor energy efficiency was 18.02–20.88%, showing an electrical yield between 456 and 555 kWh/t. The cold gas efficiency obtained was 58.51–80.60%. The chemical properties seem to correlate the most with the production and characteristics of syngas, charcoal or ash during gasification. Finally, 5 species presented different properties, but the production and efficiency of the gasifier was little affected by these differences, but Eucalyptus saligna was less efficient parameters for thermal energy and electricity generation.

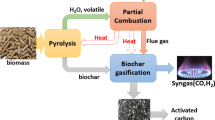

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets used during the current work are available from the corresponding author request.

Abbreviations

- BC:

-

Bark content

- C:

-

Carbon content

- CC:

-

Cellulose content

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- CH4 :

-

Methane

- Dchips :

-

Chip density

- EMC:

-

Equilibrium moisture content

- H2 :

-

Hydrogen

- H2O:

-

Water

- LC:

-

Lignin content

- LHV:

-

Low heating value (LHV) and volatile content (VC)

- MC:

-

Moisture content

- MC-G:

-

Moisture content at feedstock gasification

- MC-OD:

-

Moisture content at oven-dried condition

- N2 :

-

Nitrogen

- O2 :

-

Oxygen

- S:

-

Sulfur content

- TOC:

-

Total organic carbon

- VC:

-

Volatile content

References

Roberts, D., Johansson, E.M., Hoffman, I., Becidan, B., Ciceri, M., Murphy, G., Trois, F., Durran, T.P.:Material and Energy valorisation of waste in a circular economy. IEA Bioenergy. Task report 36. (2022) https://www.ieabioenergy.com/wp-content/uploads/2022/05/T36_Waste_Circuar_Economy_final_report.pdf. Acessed 12 Dec 2022

Jordaan, S.M., Combs, C., Guenther, E.: Life cycle assessment of electricity generation: A systematic review of spatiotemporal methods. Adv. Appl. Energy 3, 100058 (2021). https://doi.org/10.1016/j.adapen.2021.100058

Onour, I.A., Abdo, M.M.: Sensitivity of crude oil price change to major global factors and to Russian-Ukraine war crisis. J. Sustain. Bus Econ. 5(2), 4641 (2022). https://doi.org/10.30564/jsbe.v5i2.4641

Hernández-Chaverri, R.A., Buenrostro-Figueroa, J.J.: Biomass: biorefinery as a model to boost the bioeconomy in Costa Rica, a review. Agronomía Mesoamericana 32(3), 1047–1070 (2021). https://doi.org/10.15517/AM.V32I3.43736

Popp, J., Kovács, S., Oláh, J., Divéki, Z., Balázs, E.: Bioeconomy: Biomass and biomass-based energy supply and demand. New Biotechnol. 60, 76–84 (2021). https://doi.org/10.1016/j.nbt.2020.10.004

Alonso, D.M., Hakim, S.H., Zhou, S., Won, W., Hosseinaei, O., Tao, J., Garcia-Negron, V., Motagamwala, A.H., Mellmer, M.A., Huang, K., Houtman, C.J.: Increasing the revenue from lignocellulosic biomass: Maximizing feedstock utilization. Sci. Adv. 3(5), e1603301 (2017). https://doi.org/10.1016/j.rser.2014.01.07910.1126/sciadv.16033

Abuelnuor, A.A., Wahid, M.A., Hosseini, S.E., Saat, A., Saqr, K.M., Sait, H.H., Osman, M.: Characteristics of biomass in flameless combustion: a review. Renew. Sustain. Energy Rev. 33, 363–370 (2014). https://doi.org/10.1016/j.rser.2014.01.079

Valverde, J.C., Arias, D., Campos, R., Jiménez, M.F., Brenes, L.: Forest and agro-industrial residues and bioeconomy: perception of use in the energy market in Costa Rica. Energy, Ecol. Environ. 6(3), 232–243 (2021). https://doi.org/10.1007/s40974-020-00172-4

Torres, C., Urvina, L., de Lasa, H.: A chemical equilibrium model for biomass gasification. Application to Costa Rican coffee pulp transformation unit. Biomass Bioenergy 123, 89–103 (2019). https://doi.org/10.1016/j.biombioe.2019.01.025

Moya, R., Tenorio, C., Oporto, G.: Short rotation wood crops in Latin American: a review on status and potential uses as biofuel. Energies 12(4), 705 (2019). https://doi.org/10.3390/en12040705

Tenorio, C., Moya, R., Tomazello-Filho, M., Valaert, J.: Quality of pellets made from agricultural and forestry crops in Costa Rican tropical climates. BioRes 10(1), 482–498 (2015)

Balaguer-Benlliure, V., Moya, R., Gaitán-Alvarez, J.: Physical and energy characteristics, compression strength, and chemical modification of charcoal produced from sixteen tropical woods in Costa Rica. J. Sustain. For. (2023). https://doi.org/10.1080/10549811.2021.1978096

Moya, R., Rodriguez-Zuñiga, A., Puente-Urbina, A., Gaitan-Alvarez, J.: Study of light, middle and severe torrefaction and effects of extractives and chemical compositions on torrefaction process by thermogravimetric analyses in five fast-growing plantation of Costa Rica. Energy 149, 1–10 (2018). https://doi.org/10.1016/j.energy.2018.02.049

Sharma, P., Gupta, B., Pandey, M., Bisen, K.S., Baredar, P.: Downdraft biomass gasification: a review on concepts, designs analysis, modelling and recent advances. Mater. Today: Proc. 46, 5333–5341 (2021). https://doi.org/10.1016/j.matpr.2020.08.789

Pérez, J.F., Melgar, A., Benjumea, P.N.: Effect of operating and design parameters on the gasification/combustion process of waste biomass in fixed bed downdraft reactors: an experimental study. Fuel 96, 487–496 (2012). https://doi.org/10.1016/j.fuel.2012.01.064

De Lasa, H., Salaices, E., Mazumder, J., Lucky, R.: Catalytic steam gasification of biomass: catalysts, thermodynamics and kinetics. Chem. Rev. 111(9), 5404–5433 (2011). https://doi.org/10.1021/cr200024w

Verma, S., Dregulo, A.M., Kumar, V., Bhargava, P.C., Khan, N., Singh, A., Sun, X., Sindhu, R., Binod, P., Shang, Z., Pandey, A., Awasthi, M.K.: Reaction engineering during biomass gasification and conversion to energy. Energy 266, 126458 (2023). https://doi.org/10.1016/j.energy.2022.126458

Dhaundiyal, A., Chandra, T.: Performance evaluation of throatless gasifier using pine needles as a feedstock for power generation. Acta Technol. Agric. 19(1), 10–18 (2016). https://doi.org/10.1515/ata-2016-0003

Evaristo, R.B.W., Viana, N.A., Guimarães, M.G., do Vale, A.T., de Macedo, J.L., Ghesti, G.F.: Evaluation of waste biomass gasification for local community development in central region of Brazil. Biomass Convers. Biorefin. 12, 2823–2834 (2020). https://doi.org/10.1007/s13399-020-00821-y

Sansaniwal, S., Pal, K., Rosen, M., Tyagi, S.: Recent advances in the development of biomass gasification technology: a comprehensive review. Renew. Sustain. Energy Rev. 72, 363–384 (2017). https://doi.org/10.1016/J.RSER.2017.01.038

Dahou, T., Defoort, F., Khiari, B., Labaki, M., Dupont, C., Jeguirim, M.: Role of inorganics on the biomass char gasification reactivity: a review involving reaction mechanisms and kinetics models. Renew. Sustain. Energy Rev. 135, 110136 (2021). https://doi.org/10.1016/j.rser.2020.110136

Dejtrakulwong, C., Patumsawad, S.: Four zones modeling of the downdraft biomass gasification process: effects of moisture content and air to fuel ratio. Energy Procedia 52, 142–149 (2014). https://doi.org/10.1016/j.egypro.2014.07.064

Susastriawan, A.P., Saptoadi, H.: Small-scale downdraft gasifiers for biomass gasification: a review. Renew. Sustain. Energy Rev. 76, 989–1003 (2017). https://doi.org/10.1016/j.rser.2017.03.112

Pérez, S., Renedo, C., Ortiz, A., Ortiz, F.: Residual biomass in Eucalyptus globulus plantations according to stand quality. Biomass Bioenergy 141, 105699 (2022). https://doi.org/10.1016/j.biombioe.2020.105699

Torres, C., Chaves, M., Urvina, L., Moya, R.: Evaluación de la incidencia de pellets y astillas de madera en el desempeño de un gasificador tipo “downdraft.” Rev. For. Mesoamericana Kurú 15, 25–36 (2018). https://doi.org/10.18845/rfmk.v15i1.3847

Rios, M.L.V., González, A.M., Lora, E.E.S., del Olmo, O.A.: Reduction of tar generated during biomass gasification: a review. Biomass Bioenergy 108, 345–370 (2018). https://doi.org/10.1016/j.biombioe.2017.12.002

Safarian, S., Unnþórsson, R., Richter, C.: A review of biomass gasification modelling. Renew. Sustain. Energy Rev. 110, 378–391 (2019). https://doi.org/10.1016/j.rser.2019.05.003

Jarungthammachote, S., Dutta, A.: Equilibrium modeling of gasification: Gibbs free energy minimization approach and its application to spouted bed and spout-fluid bed gasifiers. Energy Convers. Manag. 49(6), 1345–1356 (2008). https://doi.org/10.1016/j.enconman.2008.01.006

Wang, Y., Yoshiie, R., Ueki, Y., Naruse, I.: Characteristics of biomass gasification by oxygen-enriched air in small-scale auto-thermal packed-bed gasifier for regional distribution. Fuel 342, 127852 (2023). https://doi.org/10.1016/j.fuel.2023.127852

Arâmburu, A., Lunkes, N., de Cademartori, P.H.G., Gatto, D.A., Missio, A.L., Delucis, R.A.: Forestry wastes: technical concepts, economic circularity, and sustainability approaches. In: Jacob-Lopes, E., Queiroz Zepka, L., Costa Deprá, M. (eds.) Handbook of waste biorefinery, pp. 369–415. Springer, Cham (2022). https://doi.org/10.1007/978-3-031-06562-0_14

Awais, M., Li, W., Munir, A., Omar, M.M., Ajmal, M.: Experimental investigation of downdraft biomass gasifier fed by sugarcane bagasse and coconut shells. Biomass Convers. Biorefin. 11, 429–444 (2021). https://doi.org/10.1007/s13399-020-00690-5

Reed, T.B., Das, A.:Handbook of biomass downdraft gasifier engine systems. Biomass Energy Foundation. Solar Energy Research Institute. U.S. Department of Energy, Golden, Colorado, USA. P. 148 (1988) https://www.nrel.gov/docs/legosti/old/3022.pdf

Song, H., Yang, G., Xue, P., Li, Y., Zou, J., Wang, S., Yang, H., Chen, H.: Recent development of biomass gasification for H2 rich gas production. Prog. Energy Combust. Sci. 10, 100059 (2022). https://doi.org/10.1016/j.jaecs.2022.100059

Kong, G., Zhang, X., Wang, K., Li, J., Zhou, L., Wang, J., Zhang, X., Han, L.: Coupling biomass gasification and inline co-steam reforming: Synergistic effect on promotion of hydrogen production and tar removal. Fuel Proc Techn 243, 107689 (2023). https://doi.org/10.1016/j.fuproc.2023.107689

Suryawanshi, S.J., Shewale, V.C., Thakare, R.S., Yarasu, R.B.: Parametric study of different biomass feedstocks used for gasification process of gasifier—a literature review. Biomass Convers. Biorefin. 1, 1–12 (2021). https://doi.org/10.1007/s13399-021-01805-2

Agrawal, A., Sood, D.: Development and performance analysis of pine needle based downdraft gasifier system. In: Baredar, P.V., Tangellapalli, S., Solanki, C.S. (eds.) Advances in clean energy technologies: select proceedings of ICET 2020, pp. 163–170. Springer, Singapore (2021). https://doi.org/10.1007/978-981-16-0235-1_13

Chang, C.T., Costa, M., La Villetta, M., Macaluso, A., Piazzullo, D., Vanoli, L.: Thermo-economic analyses of a Taiwanese combined CHP system fuelled with syngas from rice husk gasification. Energy 167, 766–780 (2019). https://doi.org/10.1016/j.energy.2018.11.012

Rupesh, S., Muraleedharan, C., Arun, P.: Energy and exergy analysis of syngas production from different biomasses through air-steam gasification. Front. Energy 14, 607–619 (2020). https://doi.org/10.1007/s11708-016-0439-1

Chaves, L.I., da Silva, M.J., de Souza, S.N.M., Secco, D., Rosa, H.A., Nogueira, C.E.C., Frigo, E.P.: Small-scale power generation analysis: downdraft gasifier coupled to engine generator set. Renew. Sustain. Energy Rev. 58, 491–549 (2016). https://doi.org/10.1016/j.rser.2015.12.033

Littlejohns, J.V., Butler, J., Luque, L., Kannangara, M., Totolo, S.: Analysis of the performance of an integrated small-scale biomass gasification system in a Canadian context. Biomass Convers. Biorefin. 10, 311–323 (2020). https://doi.org/10.1007/s13399-019-00442-0

Montiel-Bohórquez, N.D., Pérez, J.F.: Energy valorization strategies of fallen leaves and woody biomass in a based downdraft gasification-engine power plant. Sustain Energy Technol. Assess 49, 101749 (2022). https://doi.org/10.1016/j.seta.2021.101749

La Villetta, M., Costa, M., Cirillo, D., Massarotti, N., Vanoli, L.: Performance analysis of a biomass powered micro-cogeneration system based on gasification and syngas conversion in a reciprocating engine. Energy Convers. Manag. 175, 33–48 (2018). https://doi.org/10.1016/j.enconman.2018.08.017

Urvina LA.:Propuesta de minería de datos y análisis probabilístico para la estimación de variables de proceso utilizando series de tiempo en estado estacionario y algoritmos genéticos en un gasificador de tiro descendente. Informe de Proyecto de Graduación, Licenciatura en Ingeniería Química, Universidad de Costa Rica. San Jose, Costa Rica. p. 124 (2018)

Moya, R., Tenorio, C.: Fuelwood characteristics and its relation with extractives and chemical properties of ten fast-growth species in Costa Rica. Biomass Bioenergy 56, 14–21 (2013). https://doi.org/10.1016/j.biombioe.2013.04.013

Navarro-Camacho, R., Esquivel-Segura, E., Briceño-Elizondo, E., Arias-Aguilar, D.: Estimating aboveground biomass for Eucalyptus saligna Sm. And Eucalyptus camaldulensis Dehn in the center region of Costa Rica. Rev. Forestal Mesoam Kuru 11, 22–33 (2014). https://doi.org/10.18845/rfmk.v11i27.1775

ASTM D143–21: Standard test method for small clear specimens of timber. ASTM International, West Conshohocken (2021). https://doi.org/10.1520/D0143-21

Seifert, K.: Zur frage der Cellulose-Schnellbestimmung nach der acetylaceton-methode. Das Papier 14, 104–106 (1960)

TAPPI. (2002) Technical Association of the Pulp and Paper Industry, US. Tappi T 222 om-02 revised 2002. Standart test for acid-insoluble lignin in wood and pulp. Parkway South Norcross, US, TAPPI.

ASTM D5865–04: Standard test method for gross calorific value of coal and coke. ASTM International, West Conshohocken (2019). https://doi.org/10.1520/D5865-13

ASTM D1762–84: Standard test method for chemical analysis of wood charcoal. ASTM International, West Conshohocken (2021)

ASTM D1102–84: Standard test method for ash in wood. ASTM International, West Conshohocken (2021). https://doi.org/10.1520/D1102-84R21

Morice, J.: Evaluación de la eficiencia energética de un sistema de gasificación comercial para la producción de electricidad a partir de residuos de madera. Informe de Proyecto de Graduación, Licenciatura en Ingeniería Química, Universidad de Costa Rica. San Jose, Costa Rica. P. 114 (2017)

Centeno, F., Mahkamov, K., Silva Lora, E.E., Andrade, R.V.: Theoretical and experimental investigations of a downdraft biomass gasifier-spark ignition engine power system. Renew. Energy 37, 97–108 (2012). https://doi.org/10.1016/j.renene.2011.06.008

Soares, J., Oliveira, A.C.: Experimental assessment of pine wood chips gasification at steady and part-load performance. Biomass Bioenergy 139, 105625 (2020). https://doi.org/10.1016/j.biombioe.2020.105625

Martínez, J.D., Mahkamov, K., Andrade, R.V., Silvaora, E.E.: Syngas production in downdraft biomass gasifiers and its application using internal combustion engines. Renew. Energy 38(1), 1e9 (2012). https://doi.org/10.1016/j.renene.2011.07.035

Martínez, L.V., Rubiano, J.E., Figueredo, M., Gómez, M.F.: Experimental study on the performance of gasification of corncobs in a downdraft fixed bed gasifier at various conditions. Renew. Energy 148, 1216–1226 (2020). https://doi.org/10.1016/j.renene.2019.10.034

Zhang, Y., Wan, L., Guan, J., Xiong, Q.A., Zhang, S., Jin, X.: A review on biomass gasification: effect of main parameters on char generation and reaction. Energy Fuels 34(11), 13438–13455 (2020). https://doi.org/10.1021/acs.energyfuels.0c02900

Şen, A.U., Pereira, H.: State-of-the-art char production with a focus on bark feedstocks: processes, design, and applications. Processes 9(1), 87 (2021). https://doi.org/10.3390/pr9010087

Vassilev, S.V., Vassileva, C.G., Vassil, S., Vassilev, V.S.: Advantages and disadvantages of composition and properties of biomass in comparison with coal: an overview. Fuel 158, 330–350 (2015). https://doi.org/10.1016/j.fuel.2015.05.050

Asmadi, M., Kawamoto, H., Saka, S.: Characteristics of softwood and hardwood pyrolysis in an ampoule reactor. J. Anal. Appl. Pyrolysis 124, 523–535 (2017). https://doi.org/10.1016/j.jaap.2017.01.029

Madadian, E., Orsat, V., Lefsrud, M.: Comparative study of temperature impact on air gasification of various types of biomass in a research-scale down-draft reactor. Energy Fuels 31(4), 4045–4053 (2017). https://doi.org/10.1021/acs.energyfuels.6b03489

Atnaw, S.M., Sulaiman, S.A., Yusup, S.: Syngas production from downdraft gasification of oil palm fronds. Energy 61, 491–501 (2013). https://doi.org/10.1016/j.energy.2013.09.039

De Filippis, P., Scarsella, M., De Caprariis, B., Uccellari, R.: Biomass gasification plant and syngas clean-up system. Energy Procedia 75, 240–245 (2015). https://doi.org/10.1016/j.egypro.2015.07.318

Channiwala, S., Parikh, P.: A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81, 1051–1063 (2002). https://doi.org/10.1016/S0016-2361(01)00131-4

Dang, Q., Zhang, X., Zhou, Y., Jia, X.: Prediction and optimization of syngas production from a kinetic-based biomass gasification process model. Fuel Process Technol. 212, 106604 (2021). https://doi.org/10.1016/j.fuproc.2020.106604

Acknowledgements

The authors wish to thank Vicerrectoría de Investigación y Extensión, of the Instituto Tecnológico de Costa Rica (ITCR, Cartago, Costa Rica) and the Chemical Engineering Department of the University of Costa Rica for this project’s financial support. Special thank to Ministerio de Ciencia, Tecnología y Telecomunicaciones (MICITT) and Comisión Nacional de Ciencia y tecnología for economical sopport (FI-084-13).

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by [Marco Chaves, Cindy Torres, Carolina Tenorio, Róger Moya and Dagoberto Arias-Aguilar. The first draft of the manuscript was written by Róger Moya and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chaves, M., Torres, C., Tenorio, C. et al. Syngas Characterization and Electric Performance Evaluation of Gasification Process Using Forest Plantation Biomass. Waste Biomass Valor 15, 1291–1308 (2024). https://doi.org/10.1007/s12649-023-02231-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02231-3