Abstract

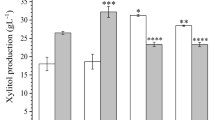

To evaluate the supplementation of the sugarcane bagasse and straw hemicellulosic hydrolysate with sugarcane syrup, which is a sucrose-rich co-product, for xylitol production by Candida guilliermondii FTI 20037. Recently, we demonstrated that sucrose supplementation to sugarcane straw hemicellulosic hydrolysate favoured this bioprocess. A mixture 1:1 of sugarcane bagasse and straw was submitted to dilute-acid hydrolysis with H2SO4 to obtain the hemicellulosic hydrolysate, which was concentrated, detoxified and autoclaved. Three sugarcane syrup concentrations (0.83, 2.50 and 3.33% v/v) were added to the hemicellulosic hydrolysate, which was also supplemented with rice bran extract, (NH4)2SO4, CaCl2·2H2O. Next, a full factorial design was performed to assess the replacement of conventional nutrients by sugarcane syrup. Fermentations were performed in 125 mL Erlenmeyer flasks containing 50 mL of fermentation medium, for 48 h at 30 °C and 200 rpm. Improvements of 16.85% and 12.24% in xylose uptake rate (1.04 ± 0.01 g L−1 h−1) and xylitol volumetric productivity (0.55 ± 0.02 g L−1 h−1), respectively, were achieved with syrup supplementation (2.50% v/v), which led to a final xylitol titer of 26.19 ± 0.02 g L−1. Conventionally employed nutrients (rice bran extract, (NH4)2SO4 and CaCl2·2H2O) did not have significant influence on xylitol production when sugarcane syrup was added to the fermentation medium. Sugarcane syrup as a nutritional supplement improved xylitol production from a mixture of bagasse and straw, becoming an alternative to reduce costs in the formulation of the fermentation medium and contributing to the integration of this bioprocess in a sugarcane biorefinery.

Graphic Abstract

Similar content being viewed by others

References

Cherubini, F.: The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energ. Convers. Manage. 51, 1412–1421 (2010)

Budzianowski, M.: High-value low-volume bioproducts coupled to bioenergies with potential to enhance business development of sustainable biorefineries. Renew. Sustain Energy Rev. 70, 793–804 (2017)

Renó, M.L.G., Olmo, O.A., Palacio, J.C.E., Lorea, E.E.S., Venturini, O.J.: Sugarcane biorefineries: case studies applied to the Brazilian sugar-alcohol industry. Energ. Convers. Manage. 86, 981–991 (2014)

Pippo, W., Luengo, C.A., Alberteris, L.A.M., Garzone, P., Cornacchia, G.: Energy recovery from sugarcane-trash in the light of 2nd generation biofuels. Part 1: current situation and environmental aspects. Waste Biomass Valor. 2, 1–16 (2011)

Long, S.P., Karp, A., Buckeridge, M.S., Davis, S.C., Jaiswal, D., Moore, P.H., Moose, S.P., Murphy, D.J., Onwona-Agyeman, S., Vonshak, A.: Feedstocks for fuels and bioenergy. In: Souza, G.M., Victoria, R.L., Joly, C.A., Verdade, L.M. (eds.) SCOPE Bioenergy and Sustainability: Bringing the Gaps, pp. 314–318. SCOPE, SCOPE (2015)

Companhia Nacional de Abasteciomento – CONAB: Acompanhamento da Safra Brasileira: Cana-de-açúcar. Primeiro levantamento. Brasilia (2017)

Werpy, T., Peterson, G.: Top value added chemicals from biomass. Volume I: Results of Screening for Potential Candidates from Sugars and Synthesis Gas. U.S. Department of Energy, Energy Efficiency and Renewable Energy. http://www1.eere.energy.gov/bioenergy/ (2004). Accessed 16 June 2014

Silva, S.S., Chandel, A.K.: d-Xylitol. Fermentative Production, Application and Commercialization. Springer, Berlin (2012)

Rueda, C., Calvo, P.A., Moncalián, G., Ruiz, G., Coz, A.: Biorefinery options to valorize the spent liquor from sulfite pulping. J. Chem. Technol. Biot. 90, 2218–2226 (2015)

Hou-Rui, Z.: Key drivers influencing the large scale production of xylitol. In: Silva, S.S., Chandel, A.K. (eds.) d-Xylitol. Fermentative Production, Application and Commercialization, pp. 267–290. Springer, Berlin (2012)

Sene, L., Vitolo, M., Felipe, M.G.A., Silva, S.S.: Effects of environmental conditions on xylose reductase and xylitol dehydrogenase production by Candida guilliermondii. Appl. Biochem. Biotechnol. 84–86, 371–380 (2000)

Granström, T., Izumori, K., Leisola, M.: A rare sugar xylitol. Part I: The biochemistry and biosynthesis of xylitol. Appl. Microbiol. Biotechnol. 74, 227–281 (2007)

Kim, J., Ryu, Y., Seo, J.: Analysis and optimization of a two-substrate fermentation for xylitol production using Candida tropicalis. J. Ind. Microbiol. Biot. 22, 181–186 (1999)

Tamburini, E., Bianchinib, E., Brunia, A., Forlani, G.: Cosubstrate effect on xylose reductase and xylitol dehydrogenase activity levels, and its consequence on xylitol production by Candida tropicalis. Enzyme Microb. Technol. 46, 352–359 (2010)

Silva, D.D.V., Felipe, M.G.A.: Effect of glucose:xylose ratio on xylose reductase and xylitol dehydrogenase activities from Candida guilliermondii in sugarcane bagasse hydrolyzate. J. Chem. Technol. Biot. 81, 1294–1300 (2006)

Hernández-Pérez, A.F., Costa, I.A.L., Silva, D.D.V., Dussán, K.J., Villela, T.R., Canettieri, E.V., Carvalho Jr., J.A., Soares Neto, T.G., Felipe, M.G.A.: Biochemical conversion of sugarcane straw hemicellulosic hydrolyzate supplemented with co-substrates for xylitol production. Bioresour. Technol. 200, 1085–1088 (2016)

Rodrigues, R.C.L.B., Felipe, M.G.A., Silva, J.B.A., Vitolo, M.: Response surface methodology for xylitol production from sugarcane bagasse hemicellulosic hydrolysate using controlled vacuum evaporation process variables. Process. Biochem. 38, 1231–1237 (2003)

Marton, J.M., Felipe, M.G.A., Silva, J.B.A., Pessoa Jr., A.: Evaluation of the activated charcoals and adsorption conditions used in the treatment of sugarcane bagasse hydrolyzate for xylitol production. Braz. J. Chem. Eng. 23, 9–21 (2006)

Arruda, P.V., Santos, J.C., Rodrigues, R.C.L.B., Silva, D.D.V., Yamakawa, C.K., Rocha, G.J.M., Junior, J.N., Pradella, J.G.C., Rossell, C.E.V., Felipe, M.G.A.: Scale up of xylitol production from sugarcane bagasse hemicellulosic hydrolysate by Candida guilliermondii FTI 20037. J. Ind. Eng. Chem. 47, 297–302 (2017)

Gouveia, E.R., Nascimento, R.T., Souto-Maior, A.M., Rocha, G.J.M.: Validação de metodologia para a caracterização química do bagaço de cana-de-açúcar. Quím Nova. 32, 1500–1503 (2009)

Duarte-Almeida, J.M., Salatino, A., Genovese, M.I., Lajolo, F.M.: Phenolic composition and antioxidant activity of culms and sugarcane (Saccharum officinarum L.) products. Food Chem. 125, 660–664 (2011)

Rao, L.V., Goli, J.K., Gentela, J., Koti, S.: Bioconversion of lignocellulosic biomass to xylitol: an overview. Bioresour. Technol. 213, 299–310 (2016)

Cortez, D.V., Roberto, I.C.: Individual and interaction effects of vanillin and syringaldehyde on the xylitol formation by Candida guilliermondii. Bioresour. Technol. 101, 1858–1865 (2010)

Preziosi-Belloy, L., Nolleau, V., Navarro, J.M.: Fermentation of hemicellulosic sugars and sugar mixture to xylitol by Candida parapsilosis. Enzyme Microb. Technol. 21, 124–129 (1997)

Wannawilai, S., Lee, W.C., Sirisansaneeyakul, S.: Furfural and glucose can enhance conversion of xylose to xylitol by Candida magnoliae TISTR 5663. J. Biotechnol. 241, 147–157 (2017)

Lee, H., Sopher, C.R., Yau, K.Y.F.: Induction of xvlose reductase and xvlitol dehydrogenase activities on mixed sugars in Candida guilliermondii. J. Chem. Technol. Biotechnol. 66, 375–379 (1996)

Walther, T., Hensirisak, P., Agblevor, F.A.: The influence of aeration and hemicellulosic sugars on xylitol production by Candida tropicalis. Bioresour. Technol. 76, 213–220 (2001)

Hernández-Pérez, A.F., Arruda, P.V., Felipe, M.G.A.: Sugarcane straw as feedstock for xylitol production by Candida guilliermondii FTI 20037. Braz. J. Microbiol. 47, 489–496 (2016)

Zhang, G.C., Liu, J.J., Kong, I.L., Kwak, S., Jin, Y.S.: Combining C6 and C5 sugar metabolism for enhancing microbial bioconversion. Curr. Opin. Chem. Biol. 29, 49–57 (2015)

Hou, J., Qiu, C., Shen, Y., Li, H., Bao, X.: Engineering of Saccharomyces cerevisiae for the efficient co-utilization of glucose and xylose. FEMS Yeast Res. 17 (2017)

Bruinenberg, P.M., Van Dikjen, J.P., Scheffers, A.: An enzymic analysis of nadph production and consumption in Candida utilis. J. Gen. Microbiol. 129, 965–971 (1983)

Tochampa, W., Sirisansaneeyakul, S., Vanichsriratana, W., Srinophakun, P., Bakker, H.H.C., Chisti, Y.: A model of xylitol production by the yeast Candida mogii. Bioprocess Biosyst. Eng. 28, 175–183 (2005)

Oh, D.K., Kim, S.Y.: Increase of xylitol yield by feeding xylose and glucose in Candida tropicalis. Appl. Microbiol. Biotechnol. 50, 419–425 (1998)

Tavares, J.M., Duarte, L.C., Collaço-Amaral, M.T., Gírio, F.M.: The influence of hexoses addition on the fermentation of d-xylose in Debaryomyces hansenii under continuous cultivation. Enzyme Microb. Technol. 26, 743–747 (2000)

Flores, C.L., Rodríguez, C., Petit, T., Gancedo, C.: Carbohydrate and energy-yielding metabolism in non-conventional yeasts. FEMS Microbiol. Rev. 24, 507–529 (2000)

Williamson, P.R., Huber, M.A., Bennett, J.E.: Role of maltase in the utilization of sucrose by Candida albicans. Biochem. J. 291, 765–771 (1993)

Oliveira, M.R., Silva, R.S.S.F., Buzato, J.B., Celligoi, M.A.P.C.: Study of levan production by Zymomonas mobilis using regional low-cost carbohydrate sources. Biochem. Eng. J. 37, 177–183 (2007)

Laksameethanasan, P., Somla, N., Janprem, S., Phochuen, N.: Clarification of sugarcane juice for syrup production. Procedia Eng. 32, 141–147 (2012)

Pimpakan, P., Yongmanitchai, W., Limtong, S.: Bioethanol production from sugar cane syrup by thermo-tolerant yeast, Kluyveromyces marxianus DMKU3-1042, using fed-batch and repeated-batch fermentation in a nonsterile system. Kasetsart. Nat. Sci. 46, 582–591 (2012)

Granström, T., Ojamo, H., Leisola, M.: Chemostat study of xylitol production by Candida guilliermondii. Appl. Microbiol. Biotechnol. 55, 36–42 (2001)

Rodrigues, R.C.L.B., Sene, L., Matos, G.S., Roberto, I.C., Pessoa Jr., A., Felipe, M.G.A.: Enhanced xylitol production by precultivation of Candida guilliermondii cells in sugarcane bagasse hemicellulosic hydrolysate. Curr. Microbiol. 53, 53–59 (2006)

Wen, X., Sidhu, S., Horemans, S.K.C., Sooksawat, N., Harner, N.K., Bajwa, P.K., Yuan, Z., Lee, H.: Exceptional hexose-fermenting ability of the xylitol-producing yeast Candida guilliermondii FTI 20037. J. Biosci. Bioeng. 121, 631–637 (2016)

Rodrigues, R.C.L.B., Felipe, M.G.A., Roberto, I.C., Vitolo, M.: Batch xylitol production by Candida guilliermondii FTI 20037 from sugarcane bagasse hemicellulosic hydrolyzate at controlled pH values. Bioprocess Biosyst. Eng. 26, 103–107 (2003)

Hahn-Hägerdal, B., Jeppsson, H., Skoog, K., Prior, B.A.: Biochemistry and physiology of xylose fermentation by yeasts. Enzyme Microb. Technol. 16, 933–943 (1994)

Prati, P., Camargo, G.A.: Características do caldo de cana e sua influência na estabilidade da bebida. BioEng 2, 037–044 (2008)

Doelle, H.W., Kennedy, L.D., Doelle, M.B.: Scale-up of ethanol production from sugarcane using Zymomonas mobilis. Biotechnol. Lett. 13, 131–136 (1991)

Nualsri, C., Reungsang, A., Plangklang, P.: Biochemical hydrogen and methane potential of sugarcane syrup using two-stage anaerobic fermentation process. Ind. Crop. Prod. 82, 88–99 (2016)

Acknowledgement

This work was supported by the São Paulo Research Foundation (FAPESP) (Process 2016/22179-0 and Scholarship 2016/05971-2) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico, Brazil).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hernández-Pérez, A.F., Chaves-Villamil, A.C., de Arruda, P.V. et al. Sugarcane Syrup Improves Xylitol Bioproduction from Sugarcane Bagasse and Straw Hemicellulosic Hydrolysate. Waste Biomass Valor 11, 4215–4224 (2020). https://doi.org/10.1007/s12649-019-00742-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00742-6