Abstract

Purpose

Barley straw from brewing process is an attractive and renewable raw material for the production of biofuel and useful chemicals, such as xylitol. It is necessary to determine the best conditions of biomass hydrolysis and fermentation for boosting the incorporation of this biomass in a biorefinery.

Methods

We optimized the conditions for acid hydrolysis of barley straw to obtain a hemicellulosic hydrolysate rich in xylose with low energy consumption. Moreover, the energy consumption was simulated per quantity of xylose extracted. In order to obtain a hydrolysate with the highest xylose extraction efficiency (99%), low inhibitors concentration and energy consumption (8.41 KW/Kg Xylose), we used 1.0% H2SO4 (w/v) at 120 °C, with 1:10 dry-weight/acid solution for 40 min. We also optimized the medium composition to improve xylitol production by Candida guilliermondii.

Results

The hemicellulosic hydrolysate was used as a fermentation medium and the best condition showing the highest xylitol volumetric productivity (0.69 g L−1 h−1) by C. guilliermondii was found to be 60 g L−1 initial xylose supplemented with 1.5 g L−1 (NH4)2SO4, 0.75 CaCl2 and 8.75 g L−1 rice bran extract.

Conclusions

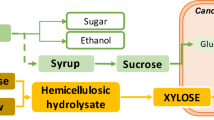

It can be concluded that barley straw can be used in biorefinery, wherein the hemicellulose fraction would be utilized to produce xylitol and the cellulosic fraction (more accessible to enzymatic hydrolysis after pre-treatment) would be used for the production of cellulosic ethanol.

Graphical Abstract

Similar content being viewed by others

References

CONAB: Acompanhamento da Safra Brasileira de Grãos. http://www.conab.gov.br/OlalaCMS/uploads/arquivos/15_12_11_11_02_58_boletim_graos_dezembro_2015.pdf (2015). Accessed 14 Dec 2015

Bowyer, J.L., Stockmann, V.E.: Agricultural residues an exciting bio-based raw material for the global panels industry. For. Prod. J. 51(01), 10–21 (2001)

Yalçın, E., Çelik, S., Akar, T., Sayim, I., Köksel, H.: Effects of genotype and environment on β-glucan and dietary fiber contents of hull-less barleys grown in Turkey. Food Chem. 101(1), 171–176 (2007). https://doi.org/10.1016/j.foodchem.2006.01.010

Cervieri Júnior, O., Júnior, T., Galinari, J.R., Rawet, R., Silveira, E.L.: C.T.J.d.: O setor de bebidas no Brasil - BNDES Setorial. https://web.bndes.gov.br/bib/jspui/handle/1408/3462 (2014). Accessed 05 Nov 2015

Zhu, Z., Toor, S.S., Rosendahl, L., Yu, D., Chen, G.: Influence of alkali catalyst on product yield and properties via hydrothermal liquefaction of barley straw. Energy. 80, 284–292 (2015). https://doi.org/10.1016/j.energy.2014.11.071

Saha, B.C., Cotta, M.A.: Comparison of pretreatment strategies for enzymatic saccharification and fermentation of barley straw to ethanol. New Biotechnol. 27(1), 10–16 (2010). https://doi.org/10.1016/j.nbt.2009.10.005

Sun, R.C., Sun, X.F.: Fractional and structural characterization of hemicelluloses isolated by alkali and alkaline peroxide from barley straw. Carbohydr. Polym. 49(4), 415–423 (2002). https://doi.org/10.1016/S0144-8617(01)00349-6

Sun, X.-F., Jing, Z., Fowler, P., Wu, Y., Rajaratnam, M.: Structural characterization and isolation of lignin and hemicelluloses from barley straw. Ind. Crops Prod. 33(3), 588–598 (2011). https://doi.org/10.1016/j.indcrop.2010.12.005

Sheikh, M.M., Kim, C.H., Park, H.H., Nam, H.G., Lee, G.S., Jo, H.S., Lee, J.Y., Kim, J.W.: A synergistic effect of pretreatment on cell wall structural changes in barley straw (Hordeum vulgare L.) for efficient bioethanol production. J. Sci. Food Agric. 95(4), 843–850 (2015). https://doi.org/10.1002/jsfa.7004

Yu, A., Kim, Y., Han, M., Choi, G.-W., Chung, B.: Bioconversion of barley straw to ethanol by a Lactobacillus plantarum and ethanolysis. J. Biosci. Bioeng. 108(Supplement 1), S51 (2009). https://doi.org/10.1016/j.jbiosc.2009.08.146

Alex Marvin, W., Schmidt, L.D., Benjaafar, S., Tiffany, D.G., Daoutidis, P.: Economic optimization of a lignocellulosic biomass-to-ethanol supply chain. Chem. Eng. Sci. 67(1), 68–79 (2012). https://doi.org/10.1016/j.ces.2011.05.055

Sene, L., Arruda, P.V., Oliveira, S.M.M., Felipe, M.D.G.A.: Evaluation of sorghum straw hemicellulosic hydrolysate for xylitol production. New Biotechnol. 25, S226–S227 (2009). https://doi.org/10.1016/j.nbt.2009.06.196

Dussán, K.J., Silva, D.D.V., Perez, V.H., da Silva, S.S.: Evaluation of oxygen availability on ethanol production from sugarcane bagasse hydrolysate in a batch bioreactor using two strains of xylose-fermenting yeast. Renew. Energy. 87, 703–710 (2016). https://doi.org/10.1016/j.renene.2015.10.065

Saritha, M., Arora, A., Lata: Biological pretreatment of lignocellulosic substrates for enhanced delignification and enzymatic digestibility. Indian J. Microbiol. 52(2), 122–130 (2012). https://doi.org/10.1007/s12088-011-0199-x

Akpinar, Ö, Usal, G.: Investigation of the effect of temperature and alkaline concentration on the solubilization of phenolic acids from dilute acid-pretreated wheat straw. Food Bioprod. Process. 95, 272–280 (2015). https://doi.org/10.1016/j.fbp.2014.11.001

Müller-Langer, F., Kaltschmitt, M.: Biofuels from lignocellulosic biomass - a multi-criteria approach for comparing overall concepts. Biomass Convers. Biorefin. 5(1), 43–61 (2015). https://doi.org/10.1007/s13399-014-0125-7

Laborel-Préneron, A., Magniont, C., Aubert, J.-E.: Characterization of barley straw, hemp shiv and corn cob as resources for bioaggregate based building materials. Waste Biomass Valoriz. (2017). https://doi.org/10.1007/s12649-017-9895-z

Yang, M., Kuittinen, S., Zhang, J., Vepsäläinen, J., Keinänen, M., Pappinen, A.: Co-fermentation of hemicellulose and starch from barley straw and grain for efficient pentoses utilization in acetone–butanol–ethanol production. Bioresour. Technol. 179, 128–135 (2015). https://doi.org/10.1016/j.biortech.2014.12.005

Nghiem, N.P., Kim, T.H., Yoo, C.G., Hicks, K.B.: Enzymatic fractionation of SAA-pretreated barley straw for production of fuel ethanol and astaxanthin as a value-added co-product. Appl. Biochem. Biotechnol. 171(2), 341–351 (2013). https://doi.org/10.1007/s12010-013-0374-0

Rafiqul, I.S.M., Sakinah, A.M.M., Zularisam, A.W.: Evaluation of sawdust hemicellulosic hydrolysate for bioproduction of xylitol by enzyme xylose reductase. Food Bioprod. Process. 94, 82–89 (2015). https://doi.org/10.1016/j.fbp.2015.01.005

Sato, H., Ide, Y., Nasu, M., Numabe, Y.: Effects of xylitol on the femur and mandibular bone in ovariectomized rats. Oral Radiol. 28(1), 38–47 (2012). https://doi.org/10.1007/s11282-011-0079-4

Honkala, S., Runnel, R., Saag, M., Olak, J., Nommela, R., Russak, S., Makinen, P.L., Vahlberg, T., Falony, G., Makinen, K., Honkala, E.: Effect of erythritol and xylitol on dental caries prevention in children. Caries Res. 48(5), 482–490 (2014). https://doi.org/10.1159/000358399

Vernacchio, L., Corwin, M.J., Vezina, R.M., Pelton, S.I., Feldman, H.A., Coyne-Beasley, T., Mitchell, A.A.: Xylitol syrup for the prevention of acute otitis media. Pediatrics. 133(2), 289–295 (2014). https://doi.org/10.1542/peds.2013-2373

Heikkila, H., Ojamo, H., Tylli, M., Ravanko, V., Nurmi, J., Haimi, P., Alen, R., Koivikko, H.: Process for the production of xylitol. New York (US) Patent

Felipe, M.G.A.: Biotechnological Production of Xylitol from Lignocellulosic Materials. In: Lignocellulose Biodegradation, vol. 889. ACS Symposium Series, vol. 889, pp. 300–315. American Chemical Society: (2004)

Chandel, A., Antunes, F.F., de Arruda, P., Milessi, T.S., da Silva, S., de Almeida Felipe, M.: Dilute acid hydrolysis of agro-residues for the depolymerization of hemicellulose: state-of-the-art. In: da Silva, S.S., Chandel, A.K. (eds.) D-Xylitol, pp. 39–61. Springer, Berlin Heidelberg (2012)

Industry Experts: Xylitol—A Global Market Overview. In., p. 258. (2017)

Domínguez, J.M., Salgado, J.M., Rodríguez, N., Cortés, S.: Biotechnological Production of Xylitol from Agro-Industrial Wastes. In: El-Samragy, Y. (ed.) Food Additive. pp. 139–156. InTech, (2012)

Hamelinck, C.N., Hooijdonk, G.v., Faaij, A.P.C.: Ethanol from lignocellulosic biomass: techno-economic performance in short-, middle- and long-term. Biomass Bioenergy. 28(4), 384–410 (2005). https://doi.org/10.1016/j.biombioe.2004.09.002

Canilha, L., Chandel, A.K., Suzane dos Santos Milessi, T., Antunes, F.A.F., Luiz da Costa Freitas, W., das Gracas Almeida Felipe, M., da Silva, S.S.: Bioconversion of sugarcane biomass into ethanol: an overview about composition, pretreatment methods, detoxification of hydrolysates, enzymatic saccharification, and ethanol fermentation. J. Biomed. Biotechnol. (2012)

Cortez, D.V., Roberto, I.C., Barbosa, M.H.P., Milagres, A.M.F.: Evaluation of cellulosic and hemicellulosic hydrolysate fermentability from sugarcane bagasse hybrids with different compositions. Biomass Convers. Biorefin. 4(4), 351–356 (2014). https://doi.org/10.1007/s13399-014-0119-5

Dias, M.O.S., Ensinas, A.V., Nebra, S.A., Maciel Filho, R., Rossell, C.E.V., Maciel, M.R.W.: Production of bioethanol and other bio-based materials from sugarcane bagasse: integration to conventional bioethanol production process. Chem. Eng. Res. Des. 87(9), 1206–1216 (2009). https://doi.org/10.1016/j.cherd.2009.06.020

Rosgaard, L., Pedersen, S., Meyer, A.S.: Comparison of different pretreatment strategies for enzymatic hydrolysis of wheat and barley straw. Appl. Biochem. Biotechnol. 143(3), 284–296 (2007)

Iroba, K.L., Tabil, L.G., Sokhansanj, S., Dumonceaux, T.: Pretreatment and fractionation of barley straw using steam explosion at low severity factor. Biomass Bioenergy 66(Supplement C), 286–300 (2014). https://doi.org/10.1016/j.biombioe.2014.02.002

Kim, S.B., Lee, J.H., Oh, K.K., Lee, S.J., Lee, J.Y., Kim, J.S., Kim, S.W.: Dilute acid pretreatment of barley straw and its saccharification and fermentation. Biotechnol. Bioprocess. Eng. 16(4), 725 (2011). https://doi.org/10.1007/s12257-010-0305-7

Schneider, L., Haverinen, J., Jaakkola, M., Lassi, U.: Pretreatment and fractionation of lignocellulosic barley straw by mechanocatalysis. Chem. Eng. J. 327(Supplement C), 898–905 (2017). https://doi.org/10.1016/j.cej.2017.06.175

Cardona Alzate, C.A., Sánchez Toro, O.J.: Energy consumption analysis of integrated flowsheets for production of fuel ethanol from lignocellulosic biomass. Energy. 31(13), 2447–2459 (2006). https://doi.org/10.1016/j.energy.2005.10.020

Moncada, J., El-Halwagi, M.M., Cardona, C.A.: Techno-economic analysis for a sugarcane biorefinery: Colombian case. Bioresour. Technol. 135(Supplement C), 533–543 (2013). https://doi.org/10.1016/j.biortech.2012.08.137

Quintero, J.A., Moncada, J., Cardona, C.A.: Techno-economic analysis of bioethanol production from lignocellulosic residues in Colombia: a process simulation approach. Bioresour. Technol. 139, 300–307 (2013). https://doi.org/10.1016/j.biortech.2013.04.048

Palmqvist, E., Hahn-Hägerdal, B.: Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour. Technol. 74(1), 17–24 (2000). https://doi.org/10.1016/S0960-8524(99)00160-1

Ur-Rehman, S., Mushtaq, Z., Zahoor, T., Jamil, A., Murtaza, M.A.: Xylitol: a review on bioproduction, application, health benefits, and related safety issues. Crit. Rev. Food Sci. Nutr. 55(11), 1514–1528 (2015). https://doi.org/10.1080/10408398.2012.702288

Villa, P., Felipe, M.G.A., Rodriguez, R.C.L., Vitolo, M., Reis, E.L., Silva, S.S.: Influence of phenolic compounds on the bioprocess of xylitol production by Candida guilliermondii. In: Esbes-2 European Symposium on Biochemical Engineering Science, Porto, Portugal: (1998)

Kelly, C., Jones, O., Barnhart, C., Lajoie, C.: Effect of furfural, vanillin and syringaldehyde on Candida guilliermondii growth and xylitol biosynthesis. Appl. Biochem. Biotechnol. 148(1–3), 97–108 (2008). https://doi.org/10.1007/s12010-007-8103-1

Mills, T.Y., Sandoval, N.R., Gill, R.T.: Cellulosic hydrolysate toxicity and tolerance mechanisms in Escherichia coli. Biotechnol. Biofuels. 2, 26 (2009). https://doi.org/10.1186/1754-6834-2-26

Lawford, H.G., Rousseau, J.D.: Improving fermentation performance of recombinant Zymomonas in acetic acid-containing media. Appl. Biochem. Biotechnol. 70–72, 161–172 (1998)

Felipe, M.G., Vieira, D.C., Vitolo, M., Silva, S.S., Roberto, I.C., Manchilha, I.M.: Effect of acetic acid on xylose fermentation to xylitol by Candida guilliermondii. J. Basic Microbiol. 35(3), 171–177 (1995)

Silva, D.D.V., Felipe, M.G.A., Mancilha, I.M., Luchese, R.H., Silva, S.S.: Inhibitory effect of acetic acid on bioconversion of xylose in xylitol by Candida guilliermondii in sugarcane bagasse hydrolysate. Braz. J. Microbiol. 35, 248–254 (2004)

Silva, D.D., Candido, E.J., Arruda, P.V., Silva, S.S., Felipe, M.G.: New cultive medium for bioconversion of C5 fraction from sugarcane bagasse using rice bran extract. Braz. J. Microbiol. 45(4), 1469–1475 (2014)

de Albuquerque, T.L., Gomes, S.D.L., Marques, J.E. Jr., Silva Jr, I.J.d., Rocha, M.V.P.: Xylitol production from cashew apple bagasse by Kluyveromyces marxianus CCA510. Catal. Today. 255, 33–40 (2015). https://doi.org/10.1016/j.cattod.2014.10.054

Mussatto, S.I., Roberto, I.C.: Establishment of the optimum initial xylose concentration and nutritional supplementation of brewer’s spent grain hydrolysate for xylitol production by Candida guilliermondii. Process Biochem. 43(5), 540–546 (2008). https://doi.org/10.1016/j.procbio.2008.01.013

Rocha, G.J.M., Silva, F.T., Araújo, G.T., Curvelo, A.A.S.: A fast and accurate method for determination of cellulose and polyoses by HPLC. In: Ramos, L.P. (ed.) V Brazilian Symposium on the Chemistry of Lignin and Other Wood Components, Paraná: 1997, pp. 113–115. Sepia Editora e Grafica LT

Gouveia, E.R., Nascimento, R.T., Souto-Maior, A.M., Rocha, G.J.M.: Validação de metodologia para a caracterização química de bagaço de cana-de-açúcar. Quim. Nova 32(6), 1500–1503 (2009)

Marton, J.M., Felipe, M.G.A., Almeida e Silva, J.B., Pessoa Júnior, A.: Evaluation of the activated charcoals and adsorption conditions used in the treatment of sugarcane bagasse hydrolysate for xylitol production. Braz. J. Chem. Eng. 23, 9–21 (2006)

Silva, D.D.V., Felipe, M.G.A., Mancilha, I.M., Luchese, R.H.: Evaluation of the conditions used in the preparation of sugarcane bagasse hydrolysate for improvement of the xylitol production by fermentative process. In: XIV Simpósio Nacional de Fermentações, Florianopolis, SC, Brazil (2003) 2003)

Wooley, R., Putsche, V.: Development of an ASPEN PLUS physical property database for biofuels components, p. 38. National Renewable Energy Laboratory, Golden (1996)

Panagiotopoulos, I.A., Bakker, R.R., de Vrije, T., Claassen, P.A.M., Koukios, E.G.: Dilute-acid pretreatment of barley straw for biological hydrogen production using Caldicellulosiruptor saccharolyticus. Int. J. Hydrog. Energy. 37(16), 11727–11734 (2012). https://doi.org/10.1016/j.ijhydene.2012.05.124

Dussán, K.J., Silva, D.D.V., Moraes, E.J.C., Arruda, P.V., Felipe, M.G.A.: Dilute-acid hydrolysis of cellulose to glucose from sugarcane bagasse. Chem. Eng. Trans. 38, 433–438 (2014)

Castro, R.C.d.A., Roberto, I.C.: Effect of nutrient supplementation on ethanol production in different strategies of saccharification and fermentation from acid pretreated rice straw. Biomass Bioenergy. 78, 156–163 (2015). https://doi.org/10.1016/j.biombioe.2015.04.019

Won, K., Um, B., Kim, S., Oh, K.: Fractionation of barley straw with dilute sulfuric acid for improving hemicellulose recovery. Korean J. Chem. Eng. 29(5), 614–620 (2012). https://doi.org/10.1007/s11814-011-0218-y

Moncada, J., Cardona, C.A., Higuita, J.C., Vélez, J.J., López-Suarez, F.E.: Wood residue (Pinus patula bark) as an alternative feedstock for producing ethanol and furfural in Colombia: experimental, techno-economic and environmental assessments. Chem. Eng. Sci. 140, 309–318 (2016). https://doi.org/10.1016/j.ces.2015.10.027

da Silva, D.D.V., de Almeida Felipe, M.d.G.: Effect of glucose:xylose ratio on xylose reductase and xylitol dehydrogenase activities from Candida guilliermondii in sugarcane bagasse hydrolysate. J. Chem. Technol. Biotechnol. 81(7), 1294–1300 (2006). https://doi.org/10.1002/jctb.1570

Silva, D.D.V.D., Mancilha, I.M.D., Silva, S.S.D., Felipe, M.D.G.D.A.: Improvement of biotechnological xylitol production by glucose during cultive of Candida guilliermondii in sugarcane bagasse hydrolysate. Braz. Arch. Biol. Technol. 50, 207–215 (2007)

Camargo, D., Sene, L., Variz, D.I.L.S., Felipe, M.d.GdA.: Xylitol bioproduction in hemicellulosic hydrolysate obtained from sorghum forage biomass. Appl. Biochem. Biotechnol. 175(8), 3628–3642 (2015). https://doi.org/10.1007/s12010-015-1531-4

Hernández-Pérez, A.F., Costa, I.A.L., Silva, D.D.V., Dussán, K.J., Villela, T.R., Canettieri, E.V., Carvalho, J.A. Jr., Neto, S., Felipe, T.G.: M.G.A.: Biochemical conversion of sugarcane straw hemicellulosic hydrolyzate supplemented with co-substrates for xylitol production. Bioresour. Technol. 200, 1085–1088 (2016). https://doi.org/10.1016/j.biortech.2015.11.036

Acknowledgements

The authors are grateful to FAPESP (Process No. 03/04800-0), CAPES and CNPq for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Moraes, E.d.C., Silva, D.D.V., Dussán, K.J. et al. Xylitol-Sweetener Production from Barley Straw: Optimization of Acid Hydrolysis Condition with the Energy Consumption Simulation. Waste Biomass Valor 11, 1837–1849 (2020). https://doi.org/10.1007/s12649-018-0501-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0501-9