Abstract

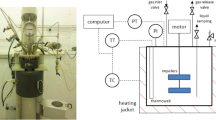

Biodiesel is an environmentally friendly fuel which can be economically produced by the use of waste culinary oil as raw material and NaOH as catalyst. However, the moisture in waste culinary oil or solid NaOH can affect the distribution of final products. In this paper, the water content of solid NaOH and waste culinary oil were determined to be 4.7 and 1.0 % respectively. A simulated transesterification system of methyl butyrate and n-butanol was catalyzed by anhydrous NaOH which was sintered at 800 °C for 2 h. The moistures in reaction system were imitated by contrived addition of water. Experimental results show that when the water content is 0.25 %, the yield of transesterification achieves the highest, simultaneously, saponification remains at the minimum level. The soybean oil and methanol were investigated as exemplary biodiesel system. The results show that when the water content is 1 %, the yield of biodiesel reaches 98.81 %, which is the highest.

Similar content being viewed by others

References

Kim, H.J., Kang, B.S., Kim, M.J., et al.: Transesterification of vegetable oil to biodiesel using heterogeneous base catalyst. Catal. Today 93, 315–320 (2004)

Meher, L.C., Vidya Sagar, D., Naik, S.N.: Technical aspects of biodiesel production by transesterification—a review. Renew. Sustain. Energy Rev. 10(3), 248–268 (2006)

Xu, G., Wu, G.: The investigation of blending properties of biodiesel and No. 0 diesel fuel. J. Jiangsu Polytech. Univ. 15(2), 16–18 (2003)

Lam, M.K., Lee, K.T., Mohamed, A.R.: Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: a review. Biotechnol. Adv. 28(4), 500–518 (2010)

Leung, D.Y.C., Wu, X., Leung, M.K.H.: A review on biodiesel production using catalyzed transesterification. Appl. Energy 87(4), 1083–1095 (2010)

Otera, Junzo: Transesterification. Chem. Rev. 93(4), 1449–1470 (1993)

Gog, A., Roman, M., Toşa, M., et al.: Biodiesel production using enzymatic transesterification—current state and perspectives. Renew. Energy 39(1), 10–16 (2012)

Marx, S., Venter, R.: Evaluation of waste process grease as feedstock for biodiesel production. Waste Biomass Valoriz. 5(1), 75–86 (2014)

Kang, X., Guo, X., You, H.: Biodiesel development in the global scene. Energy Sour. B 10(2), 155–161 (2015)

Browning, J., McClead, W., Anderson, G., et al.: Experimental Analysis of Biodiesel-Fueled Diesel Engine[J]. Proceedings of the 2015 ASEE North Central Section Conference (2015)

Marx, S., Venter, R.: Evaluation of waste process grease as feedstock for biodiesel production. Waste Biomass Valoriz. 5(1), 75–86 (2014)

Zhang, Y., Dube, M.A., McLean, D.D., et al.: Biodiesel production from waste cooking oil: 1. Process design and technological assessment. Bioresour. Technol. 89(1), 1–16 (2003)

Meng, X., Chen, G., Wang, Y.: Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Process. Technol. 89(9), 851–857 (2008)

Phan, A.N., Phan, T.M.: Biodiesel production from waste cooking oils. Fuel 87(17), 3490–3496 (2008)

Wang, Y., Ou, S., Liu, P., et al.: Preparation of biodiesel from waste cooking oil via two-step catalyzed process. Energy Convers. Manag. 48(1), 184–188 (2007)

Demirbas, A.: Biodiesel from waste cooking oil via base-catalytic and supercritical methanol transesterification. Energy Convers. Manag. 50(4), 923–927 (2009)

Pukale, D.D., Maddikeri, G.L., Gogate, P.R., et al.: Ultrasound assisted transesterification of waste cooking oil using heterogeneous solid catalyst. Ultrason. Sonochem. 22, 278–286 (2015)

Marsh, G.: Biofuels: aviation alternative? Renew. Energy Focus 9(4), 48–51 (2008)

http://www.chinadaily.com.cn/cndy/2015-03/26/content_19912292.htm

Boz, N., Degirmenbasi, N., Kalyon, D.M.: Esterification and transesterification of waste cooking oil over amberlyst 15 and modified Amberlyst 15 catalysts. Appl. Catal. B 165, 723–730 (2015)

Hájek, M., Kwiecien, J., Skopal, F.: Biodiesel: the influence of dealcoholization on reaction mixture composition after neutralization of catalyst by carbon dioxide. Fuel 96, 85–89 (2012)

Scherer, M.D., Schroeder, L., Balmant, W., et al.: Modeling and simulation of the saponification process of microalgal biomass for fatty acids production. In: 14th Brazilian Congress of Thermal Sciences and Engineering, 18–22, 2012

Glass, R.L.: Alcoholysis, saponification and the preparation of fatty acid methyl esters. Lipids 6(12), 919–925 (1971)

Eze, V.C., Phan, A.N., Harvey, A.P.: A more robust model of the biodiesel reaction, allowing identification of process conditions for significantly enhanced rate and water tolerance. Bioresour. Technol. 156, 222–231 (2014)

Eze, V.C., Harvey, A.P., Phan, A.N.: Determination of the kinetics of biodiesel saponification in alcoholic hydroxide solutions. Fuel 140, 724–730 (2015)

Ma, F., Clements, L.D., Hanna, M.A.: The effects of catalyst, free fatty acids, and water on transesterification of beef tallow[J]. Trans. ASAE 41(5), 1261 (1998)

Vasudevan, P.T., Fu, B.: Environmentally sustainable biofuels: advances in biodiesel research. Waste Biomass Valoriz. 1(1), 47–63 (2010)

Gerhard, K., Krahl, J., Gerpen, J.V. (eds.): The biodiesel handbook. Elsevier, (2015)

Dwight, T., Lakshmanan, P., Songstad, D.(eds.): Biofuels: Global Impact on Renewable Energy, Production Agriculture, and Technological Advancements. Springer, Newyork (2011)

Joshi, A.V. et al.: NaOH production from ceramic electrolytic cell. U.S. Patent 5,290,405. 1 March 1994

Dotson, R.L., Kevin J.O.: Electrolytic production of high purity alkali metal hydroxide. U.S. Patent 4,025,405. 24 May 1977

Oda, Y., Suhara, M., Endo, E.: Process for producing alkali metal hydroxide, U.S. Patent 4,065,366. 27 Dec 1977

Granados, M.L., Poves, M.D., Alonso, D.M., et al.: Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B 73(3), 317–326 (2007)

Liu, X., He, H., Wang, Y., et al.: Transesterification of soybean oil to biodiesel using CaO as a solid base catalyst. Fuel 87(2), 216–221 (2008)

Knolle, E., Linert, W., Gilly, H.: The missing color change from drying in strong base-containing absorbents is not due to the hygroscopic properties of NaOH and KOH. Anesthesiology 96, A1156 (2002)

Singh, A.K., Fernando, S.D., Hernandez, R.: Base-catalyzed fast transesterification of soybean oil using ultrasonication. Energy Fuels 21(2), 1161–1164 (2007)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 21276022), the Fundamental Research Funds for the Central Universities (FRF-BR-13-006), CNPC Innovation Foundation (2012D-5006-0208), R & D Projects of Applied Technology of Liuzhou Guangxi (2012B030101) and Petro China Company Limited Project (2011B-1303) and Liudong Hightech District Project. Industry-scale manufacture of sucrose esters was used for human friendly detergent.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, P., Chang, Z., Wang, D. et al. Effect of Water Content on Product Distribution of Base-Catalyzed Transesterification. Waste Biomass Valor 8, 95–102 (2017). https://doi.org/10.1007/s12649-016-9584-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9584-3