Abstract

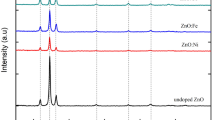

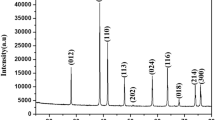

During the last two decades, researchers have been making efforts to find the most suitable metal oxides to be utilized for spintronics applications, magneto-optical devices, quantum dots, etc. Thus current research has examined the microstructural, optical, dielectric, and magnetic behavior of co-doped (Cr, Fe) tin oxide (Sn1−2xCrxFexO2−δ) nanoparticles. The Cr and Fe-doped (Sn1−xCrxO2−δ), (Sn1−xFexO2−δ) and co-doped (Cr, Fe) tin oxide (Sn1−2xCrxFexO2−δ) for x = 0.1 have been synthesized by solid-state reaction method from the tin oxide, chromium oxide, and ferric oxide prepared by co-precipitation method. Powder x-ray diffraction reveals the formation of pure rutile type tetragonal phase of samples and average crystalline size was found to be in the range of 45–54 nm. The electronic state of elements Sn, Cr, and Fe was observed to be 4+, 6+, and 3+, respectively, from x-ray photoelectron spectroscopy. The shape and size of the particles were observed to be cubic and in the range of 52–70 nm by scanning electron microscope. On the other hand, transmission electron microscopic reveals the grain size of 25–36 nm. The optical band gap determined from UV–visible absorption spectroscopy was found to be widened by doping. The maximum dielectric loss (5.3) was observed for pristine SnO2 and low loss (0.78) for co-doped (Cr, Fe) tin oxides from P–E measurement. The vibrating sample magnetometer studies show the transition from diamagnetism to ferromagnetism after co-doping. We found improvement in ferromagnetism and ferroelectricity due to co-doping, therefore the sample is suitable for high-frequency optoelectronic applications.

Similar content being viewed by others

Data availability

The raw data can be obtained on request from the corresponding author.

References

H Ohno Science 281 951 (1998).

G Prinz Science 282 1660 (1998).

S A Wolf et al Science 294 1488 (2001).

Q Chen, K Sua, H Wanga and Q Chen J. Non-Cryst. Solid 493 20 (2018).

G Shin et al ACS nano 5 10009 (2011).

J Pan, H Shen and S Mathur J. Nanotechnol. 2012 1 (2012).

K Kumari and M Ahmaruzzaman Matter. Res. Bull. 168 112446 (2023).

E T Selvi, S M Sundar, P Selvakumar and P M Ponnusamy J. Mater. Sci. Mater. Electron. 28 7713 (2017).

F Li, Q Liu, H Jiawen, J Yang and J Ma J. Phys. D: Appl. Phys. 53 353001 (2020).

X Guan, N Cai, C Yang, J Chen and P Lu Thin Solid Films 605 273 (2016).

L Chouhan and S K Srivastava J. Solid State Chem. 307 122828 (2022).

R Narzary, B Dey, L Chouhan and S Kumar Sci. Semicond. Process. 142 106477 (2022).

J Wang, D Zhou, Y Li and P Wu Vacuum 141 62 (2017).

F Liu, Z Gao, H Jin and Y Meng J. Mater. Sci. 54 10609 (2019).

S Srivastava J. Supercond. Novel Magn. 33 2501 (2020).

T Tangcharoen J. Aust. Ceram. Soc. 59 29 (2023).

M Venkatesan, R D Gunning, P Stamenov and J M D Coey J. Appl. Phys. 103 07D135 (2008).

L Li et al Vacuum 182 109681 (2020).

A Gupta, R Zhang, P Kumar, V Kumar and A Kumar Magnetochemistry 6 15 (2020).

S Gupta, D Nath, F Singh and R Das Nucl. Instrum. Methods Phys. Res. B 400 37 (2017).

L Xiong, Y Guo, J Wen, H Liu, G Yang and P Qin Adv. Funct. Mater. 28 1802757 (2018).

B Seddik, B Salima, G Houda and F Abdelhakim J. At. Mol. Condens. Nano Phys. 7 145 (2020).

S Sarmah and A Kumar Indian J. Phys. 84 1211 (2010).

F A Akgul, C Gumus, O E Ali, A H Farha, G Akgul, Y Ufuktepe and Z Liu J. Alloys Comp. 579 50 (2013).

A B Glot, R Bulpett, A I Ivon and P M Gallegos-Acevedo Phys. B: Condens. Matter 457 108 (2015).

Y Li et al NPG Asia Mater. 4 e30 (2012).

D Liu, Y Wang, X Hao, H Zheng and T Zhang Peng Zhang Sol. RRL 3 1800292 (2019).

T Isono et al J. Soc. Inf. Disp. 15 161 (2007).

K Kato J. Electron Devices Soc. 7 1201 (2019).

H W Kim et al ACS Appl. Mater. Interfaces 9 31667 (2017).

J H Bang et al. Ceram. Int. 45 7723 (2019).

H S Hong, T Dai Lam, T Trung and N Van Hieu Talanta 88 15 (2012).

B Narzary, B Dey, S N Rout, A Mondal, G Bouzerar, M Kar, S Ravi and S K Srivastava J. Alloys Comp. 934 167874 (2023).

R Narzary et al Magnetochemistry 8 150 (2022).

S K Srivastava et al Mater. Res. Express 6 126107 (2019).

K K Singha, A Mondal, M Gupta, V G Sathe, D Kumar and S K Srivastava J. Mater. Sci.: Mater. Electron. 34 1421 (2023).

B Dey et al J. Mater. Sci.: Mater. Electron. 33 2855 (2022).

H Wang, Y Yan, Y S Mohammed and X Du J. Magn. Magn. Mater. 321 337 (2009).

W Z Xiao and H Luo Phys. J. B 80 337 (2011).

L B Shi Sci. Semicond. Process. 16 877 (2013).

S B Ogale, R J Choudhary, J P Buban, S E Lofland, S R Shinde, S N Kale et al Phys. Rev. Lett. 91 077205 (2003).

N H Hong and J Sakai J. Phys. Condens. Matter 17 1697 (2005).

N Ahmad, S Khan and M M Nizam Ansari Ceram. Int. 44 15972 (2018).

M Duhan, N Kumar, A Gupta, A Singh and H Kaur Vacuum 181 109635 (2020).

D Rehani and M Saxena J. Supercond. Novel. Magn. 35 2573 (2022).

T R Cunha, I M Costa and R J S Lima J. Supercond. Nov. Magn. 26 2299 (2013).

T Ahmad J. Alloys Compd. 615 263 (2014).

E T Selvi and S M Sundar J. Mater. Sci.: Mater. Electron. 28 15021 (2017).

S Roy Condens. Matter 21 e00393 (2019).

P Mohanapriya et al J. Nanosci. Nanotechnol. 13 5391 (2013).

S A Ahmed Solid State Commun. 150 2190 (2010).

L Lin et al Vacuum 18 109681 (2020).

D S Gavaskar, P Nagaraju, Y Vijayakumar, P S Reddy and M V Ramana Reddy J. Asian Ceram. Soc. 8 605 (2020).

C V Reddy, R R Kakarla, J Shim, R R Zairov and T M Aminabhavi Env. Res. 217 114672 (2023).

S K Jain et al ACS Omega 7 14138 (2022).

M Kuppan and S Kaleemulla Condens. Matter Phys. 2014 1 (2014).

L Prakash and C Tirupathi J. Nanosci. Technol. 4 478 (2018).

R Al-Gaashani, S Radiman, N Tabet and A R Daud Mater. Sci. Eng.: B 177 462 (2012).

A R Denton and N W Ashcroft Phys. Rev. A 43 3161 (1991).

T Preethi et al Sci. Technol. 2022 1 (2022).

L Zhang, S Ge, Y Zuo, J Wang and J Qi Script. Mater. 63 953 (2010).

T Ungar and A Borbely Appl. Phys. Lett. 69 3173 (1996).

A Muiruri, M Maringa and W du Preez Mater. 13 5355 (2020).

N Lavanya, S Radhakrishnan, N Sudhan, C Sekar and S G Leonardi Nanotechnol. 25 295501 (2014).

K A Rahman et al Ionics 25 3363 (2019).

L Li et al Energy & Fuels 3 1749 (2019).

S Yang, X Song, P Zhang, J Sun and L Gao Small 10 2270 (2014).

R Awasthi, K Asokan and B Das Phys. A 125 338 (2019).

G T Rao, B Babu, R V Ravikumar, J Shim and C V Reddy Mater. Res. Express 4 125021 (2017).

S Muruganandam, K Parivathini and G Murugadoss Phys. A 127 1 (2021).

P Uniyal and K L Yadav J. Phys. Condens. Matt. 21 012205 (2009).

V Siva Jahnavia, S K Tripathy and A V N Ramalingeswara Rao Phys. B Condens. Matter 565 61 (2019).

A M Feroz, M B Khalid, C Indrajeet and G M Bhat J. Mater. Sci.: Mater. Electron. 25 1564 (2014).

S Gnanam and V Rajendran J. Sol-Gel Sci. Technol. 56 128 (2010).

M Khan and A Parveen J. Nanotechnol. Res. 2 10 (2020).

Y Y Zulfiqar, J Yang, W Wang, Z Ye and L Jianguo Ceram. Int. 42 17128 (2016).

A Sharma, M Varshney and S Kumar Nanomater Nanotechnol. 1 6 (2011).

R Adhikari and A K Das Phys. Rev. B 78 024404 (2008).

Acknowledgements

We acknowledge Dr. Vasant G. Sathe, Centre-Director of UGC-DAE Consortium for Scientific Research (Indore, India) for TEM, XPS, UV-Vis, P-E (Dielectric), and VSM measurements. We are also thankful to Late Dr. Piyush Jaiswal, (Nanotechnology department) and Prof. M. K. Dutta (Director, Centre of Advanced Studies), Dr. A.P.J.A.K.T.U (Lucknow, India) for SEM studies.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

BD: Review and editing Supervision, and investigation. AV: Conceptualization, writing original draft preparation, data curation, methodology and all work.

Corresponding author

Ethics declarations

Conflict of interest

None.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Verma, A., Das, B. Synthesis, microstructural, optical, dielectric, and magnetic behavior of pure and co-doped (Cr, Fe) tin oxide (Sn1−2xCrxFexO2−δ) nanoparticles by using both co-precipitation and solid-state reaction method. Indian J Phys (2024). https://doi.org/10.1007/s12648-024-03119-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12648-024-03119-1