Abstract

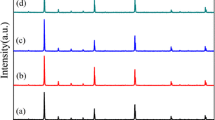

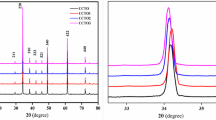

CCTO ceramics are known for their high dielectric constant and low loss, making them potential candidates for use in various electronic and energy storage applications. The dielectric properties of CCTO ceramics can be tuned by doping of various elements. In addition to the dielectric properties, Co–Ni substitution has also been found to affect other properties of CCTO ceramics, such as the thermal and electrical conductivity. Therefore, Co–Ni substitution can be a useful strategy for tailoring the properties of CCTO ceramics for specific applications. In this research work, the sol–gel auto-combustion technique is used for the synthesis of Co–Ni-substituted calcium copper titanate, Ca(1-x)Co(x)Cu3Ti(4-y)Ni(y)O22 (x = 0.0/y = 0.0, x = 0.1/y = 0.3 and x = 0.2/y = 0.4). X-ray diffraction, Fourier transform infrared spectroscopy, field emission scanning electron microscopy, and impedance analyzer have all been used to examine the structural and dielectric properties of synthesized samples. X-ray diffraction study shows the presence of crystalline structure of calcium copper titanate. The presence of peaks at 422 cm−1, 503 cm−1, and 506 cm−1 in FTIR spectra also confirms the presence of CCTO. The Debye-type relaxation technique and Maxwell–Wagner model describe dielectric characteristics. The grain boundary resistance (Rgb) significantly contributes to the dielectric properties of synthesized calcium copper titanate as seen by the Cole–Cole plot.

Similar content being viewed by others

References

P Thomas J. Eur. Ceram. Soc. 32 1681 (2011)

J Wang, J Wang, R Xu, Y Sun, B Zhang and W Chen J. Alloys Compd. 653 14 (2015)

Z Kafi and A Kompany J. Alloys Compd. 727 168 (2017)

A K Rai, N K Singh, S K Lee and K D Mandal J. Alloys Compd. 509 8901 (2011)

A F L Almeida, P B A Fechine, L C Kretly and S B Sombra J. Mater. Sci. 41 4623 (2006)

H S Kushwaha, N A Madhar, B Ilahi, P Thomas, A Halder and R Vaish Sci. Rep. 6 10 (2016)

Z Xu, H Qiang and Y Chen Chen Mater. Chem. Phys. 191 1 (2017)

T Li, D Liu, H Dai, H Xiang, Z Chen, H He and Z Chen J. Alloys Compd. 599 145 (2014)

S H Hong, D Y Kim and H M Park J. Am. Ceram. Soc. 90 2118 (2007)

K D Mandal and A K Rai J. Alloys Compd. 478 771 (2009)

A K Rai and K D Mandal J. Alloys Compd. 491 507 (2010)

S N Kane, A Mishra and A K Dutta J. Phys. Conf. Ser. 755 1 (2016)

D Capsoni, M Bini, V Massarotti, G Chiodelli, M C Mozzatic and C B Azzoni J. Solid State Chem. 177 4494 (2004)

Z Zhang, X Liu, X Wang and Y Wu J. Alloys Compd. 525 114 (2012)

I Ali, M U Islam, M Naeem, H M Khan and M A Iqbal Mater. Res. Bull. 49 338 (2013)

M J Iqbal and S Farooq Mater. Res. Bull. 44 2050 (2009)

S Ounnunkad Solid State Commun. 138 472 (2006)

G Mukhtar, J Mohammed, T T T Carol, N Halilu, S Sharma, U M Isah, S K Godara and A K Srivastava Solid State Sci. 113 106549 (2021)

A H Najafabadi Ceram. Int. 42 13625 (2016)

T Xie, L Xu and C Liu Powder Technol. 232 87 (2012)

T A Alrebdi et al. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 280 115682 (2022)

J Mohammed, T T T Carol, H Y Hafeez, D Basandrai, G R Bhadu, S K Godara, S B Narang and A K Srivastava Res. Phys. 13 102307 (2019)

M Feng and X Huang Eng. Asp. 441 556 (2014)

A S Attar, E S Sichani and S Sharafi J. Mater. Res. Technol. 6 108 (2017)

J Mohammed, T T T Carol, H Y Hafeez, B I Adamu, Y S Wudil, Z I Takai, S K Godara and A K Srivastava J. Phys. Chem. Solids 126 85 (2019)

L Singh, U S Rai, K D Mandal and N B Singh Prog. Cryst. Growth Charact. Mater. 60 15 (2014)

S Jesurani and S Kanagesan J. Mater. Sci. Mater. Electron. 23 668 (2012)

M J Iqbal, M N Ashiq and I H Gul J. Magn. Magn. Mater. 322 1720 (2010)

L Singh, U S Rai, K Mandal, B C Sin, S I Lee and Y Lee Ceram. Int. 40 10073 (2014)

Z Maleknejad, K Gheisari and A H Raouf J. Supercond. Nov. Magn. 29 2523 (2016)

T Hussain, S A Siddiqi, S Atiq and M S Awan Prog. Nat. Sci. Mater. Int. 23 487 (2013)

J Mohammed et al. Springer International Publishing 369 (2018)

P Liu, Y Lai, Y Zeng and S Wu J. Alloys Compd. 650 59 (2015)

J Liu, C G Duan and W N Mei J. Appl. Phys. 98 1 (2005)

Y Bai and J Zhou J. Magn. Magn. Mater. 278 208 (2004)

M G Chourashiya and J Y Patil Chem. Phys. 109 39 (2008)

H Malik, M A Khan, A Hussain and M F Warsi Int. 44 605 (2018)

Z Yang, L Zhang and X Chao J. Alloys Compd. 509 8716 (2011)

W Li and S Qiu J. Mater. Sci. Technol. 26 682 (2010)

L. Sahoo, S. Bhuyan, and S. N. Das Appl. Phys. A Mater. Sci. Process. 128 1 (2022)

S N Das, S Pradhan, S Bhuyan and R N P Choudhary Das J. Electron. Mater. 46 1637 (2017)

J Li, R Jia, L Hou, L Gao and K Wu Li J. Alloys Compd. 644 824 (2015)

J Mohammed et al. Ceram. Int. 46 7187 (2020)

Acknowledgements

For all of the characterization, the authors would like to acknowledge Central Instrumentation Facility (CIF), Lovely Professional University, Phagwara, India-144411.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, S., Carol, T.T.T., Mohhamed, J. et al. Impact of Co–Ni substitution on the structural and dielectric properties of calcium copper titanate. Indian J Phys 97, 4177–4185 (2023). https://doi.org/10.1007/s12648-023-02748-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-023-02748-2