Abstract

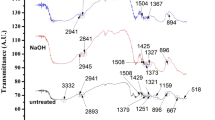

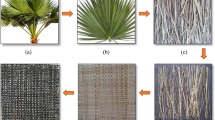

This work aims to investigate the effect of high filler loadings of SiO2 nanoparticles on the mechanical properties of pineapple leaf fiber (PALF) epoxy hybrid composites. The compression molding process was used to create the composite. To achieve the aforementioned goals, the blends were made using 25% PALF and varied weight proportions (3 wt%, 6 wt%, and 9 wt%) of SiO2 nanoparticles. Tensile, bending, impact, interlaminar shear, shoreline D hardness, and dynamic mechanical analysis were all evaluated. SEM was used to examine the morphology of the materials, and an FTIR spectrometer was used to look for the presence of organic chemicals in fiber-reinforced composite materials. The findings show that adding 25% PALF fiber and 6% SiO2 nanoparticles (D-type) to the epoxy polymer improved the thermal and mechanical properties of the composites. Even the high filler content of SiO2 (E-type) reveals the highest mechanical strength compared to the A and B types. It can be attributed to the improved interaction and homogeneous dispersion of the fillers and epoxy polymers. Moreover, the water uptake parameters of all samples were studied. The findings showed that the inclusion of reinforcements boosts the water uptake of the composite significantly. The initial deterioration rate of the SiO2-incorporated hybrids is almost the same, at about 400 °C, which is considerably greater than that of the beginning breakdown temperatures of PALF (300 °C), according to the thermography results. Due to that, the inorganic SiO2-filled PALF-reinforced polymer composites have increased degradability and generate less environmental pollution, and these biocomposites have demonstrated application in the construction, packaging, furnishings, automobile, and biotechnological domains.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included in the article. Should further data or information be required, these are available from the corresponding author upon request.

References

Ganesan V, Kaliyamoorthy B (2020) Utilization of Taguchi Technique to Enhance the Interlaminar Shear Strength of Wood Dust Filled Woven Jute Fiber Reinforced Polyester Composites in Cryogenic Environment. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1789021

Amjad A, Abidin MSZ, Alshahrani H, Ab Rahman AA (2021) Effect of fiber surface treatment and nanofiller addition on the mechanical properties of flax/pla fibre reinforced epoxy hybrid nanocomposite. Polymers 13. https://doi.org/10.3390/polym13213842

Saha A, Kumari P (2022) Functional fibers from Bambusa tulda (Northeast Indian species) and their potential for reinforcing biocomposites. Mater Today Commun 31:103800. https://doi.org/10.1016/j.mtcomm.2022.103800

Saha A, Kumar S, Zindani D (2021) Investigation of the effect of water absorption on thermomechanical and viscoelastic properties of flax-hemp-reinforced hybrid composite. Polym Compos 42:4497–4516. https://doi.org/10.1002/pc.26164

Saha A, Kumar S, Kumar A (2021) Influence of pineapple leaf particulate on mechanical, thermal and biodegradation characteristics of pineapple leaf fiber reinforced polymer composite. J Polym Res 28. https://doi.org/10.1007/s10965-021-02435-y

Mondal S, Khastgir D (2017) Elastomer reinforcement by graphene nanoplatelets and synergistic improvements of electrical and mechanical properties of composites by hybrid nano fillers of graphene-carbon black & graphene-MWCNT. Compos A Appl Sci Manuf 102:154–165. https://doi.org/10.1016/j.compositesa.2017.08.003

Asim M, Abdan K, Jawaid M et al (2015) A review on pineapple leaves fibre and its composites. Int J Polym Sci 2015. https://doi.org/10.1155/2015/950567

Johny V, Kuriakose Mani A, Palanisamy S et al (2023) Extraction and Physico-Chemical Characterization of Pineapple Crown Leaf Fibers (PCLF). Fibers 11:5. https://doi.org/10.3390/fib11010005

Mishra S, Mohanty AK, Drzal LT et al (2004) A review on pineapple leaf fibers, sisal fibers and their biocomposites. Macromol Mater Eng 289:955–974. https://doi.org/10.1002/MAME.200400132

Wisittanawat U, Thanawan S, Amornsakchai T (2014) Mechanical properties of highly aligned short pineapple leaf fiber reinforced - Nitrile rubber composite: Effect of fiber content and Bonding Agent. Polym Testing 35:20–27. https://doi.org/10.1016/j.polymertesting.2014.02.003

Kengkhetkit N, Amornsakchai T (2012) Utilisation of pineapple leaf waste for plastic reinforcement: 1. A novel extraction method for short pineapple leaf fiber. Ind Crops Prod 40:55–61. https://doi.org/10.1016/j.indcrop.2012.02.037

Todkar SS, Patil SA (2019) Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos B Eng 174:106927. https://doi.org/10.1016/j.compositesb.2019.106927

Feng NL, Malingam SD, Ping CW, Razali N (2020) Mechanical properties and water absorption of kenaf/pineapple leaf fiber-reinforced polypropylene hybrid composites. Polym Compos 41:1255–1264. https://doi.org/10.1002/pc.25451

Huda MS, Drzal LT, Mohanty AK, Misra M (2008) Effect of chemical modifications of the pineapple leaf fiber surfaces on the interfacial and mechanical properties of laminated biocomposites. Compos Interfaces 15:169–191. https://doi.org/10.1163/156855408783810920

Sumesh KR, Kavimani V, Rajeshkumar G et al (2021) Effect of banana, pineapple and coir fly ash filled with hybrid fiber epoxy based composites for mechanical and morphological study. J Mater Cycles Waste Manage 23:1277–1288. https://doi.org/10.1007/s10163-021-01196-6

Kumar S, Saha A, Bhowmik S (2022) Accelerated weathering effects on mechanical, thermal and viscoelastic properties of kenaf/pineapple biocomposite laminates for load bearing structural applications. J Appl Polym Sci 139:1–16. https://doi.org/10.1002/app.51465

Saha A, Kumari P (2023) Effect of alkaline treatment on physical, structural, mechanical and thermal properties of Bambusa tulda (Northeast Indian species) based sustainable green composites. Polym Compos. 1–25. https://doi.org/10.1002/pc.27256

Rosso P, Ye L, Friedrich K, Sprenger S (2006) A toughened epoxy resin by silica nanoparticle reinforcement. J Appl Polym Sci 100:1849–1855. https://doi.org/10.1002/APP.22805

Zhou H, Xun R, Zhou Z et al (2014) Preparation of collagen fiber/CaCO3 hybrid materials and their applications in synthetic paper. Fibers and Polymers 15:519–524. https://doi.org/10.1007/s12221-014-0519-y

Velmurugan G, Siva Shankar V, KalilRahiman M et al (2023) Effectiveness of silica addition on the mechanical properties of jute/polyester based natural composite. Mater Today Proc 72:2075–2081. https://doi.org/10.1016/j.matpr.2022.08.138

Tsai JL, Cheng YL (2009) Investigating silica nanoparticle effect on dynamic and quasi-static compressive strengths of glass fiber/epoxy nanocomposites. J Compos Mater 43:3143–3155. https://doi.org/10.1177/0021998309345317

Li Q (2018) Authors : Ac ce d M us pt. 2D Materials. 0–23

Tang C, Li X, Yin F, Hao J (2017) The performance improvement of aramid insulation paper by nano-SiO2 modification. IEEE Trans Dielectr Electr Insul 24:2400–2409. https://doi.org/10.1109/TDEI.2017.006560

Ponnusamy M, Natrayan L, Patil PP et al (2022) Multiresponse Optimization of Mechanical Behaviour of Calotropis gigantea/Nano-Silicon-Based Hybrid Nanocomposites under Cryogenic Environment. Adsorpt Sci Technol. 2022. https://doi.org/10.1155/2022/4138179

Chai R, Zhu W, Li Q et al (2022) Effect of Basalt Fiber Content on Mechanical and Tribological Properties of Copper-Matrix Composites. Metals. 12. https://doi.org/10.3390/met12111925

Wang X, Wang L, Su Q, Zheng J (2013) Use of unmodified SiO2 as nanofiller to improve mechanical properties of polymer-based nanocomposites. Compos Sci Technol 89:52–60. https://doi.org/10.1016/j.compscitech.2013.09.018

Velmurugan G, Siva Shankar V, Kaliappan S et al (2022) Effect of Aluminium Tetrahydrate Nanofiller Addition on the Mechanical and Thermal Behaviour of Luffa Fibre-Based Polyester Composites under Cryogenic Environment. J Nanomater 2022:1–10. https://doi.org/10.1155/2022/5970534

Natrayan L, Veeman D, BaskaraSethupathy S et al (2022) Influence of Nanosilica Particle Addition on Mechanical and Water Retention Properties of Natural Flax- and Sisal-Based Hybrid Nanocomposites under NaOH Conditions. Adsorpt Sci Technol 2022:1–11. https://doi.org/10.1155/2022/4026495

Natrayan L, Kumar PVA, Baskara Sethupathy S et al (2022) Effect of Nano TiO2Filler Addition on Mechanical Properties of Bamboo/Polyester Hybrid Composites and Parameters Optimized Using Grey Taguchi Method. Adsorpt Sci Technol. 2022. https://doi.org/10.1155/2022/6768900

Ponnusamy M, Natrayan L, Patil PP et al (2022) Statistical Analysis on Interlaminar Shear Strength of Nanosilica Addition with Woven Dharbai/Epoxy Hybrid Nanocomposites under Cryogenic Environment by Taguchi Technique. Adsorpt Sci Technol. 2022. https://doi.org/10.1155/2022/6571515

Sekar S, Suresh Kumar S, Vigneshwaran S, Velmurugan G (2020) Evaluation of Mechanical and Water Absorption Behavior of Natural Fiber-Reinforced Hybrid Biocomposites. J Nat Fibers 00:1–11. https://doi.org/10.1080/15440478.2020.1788487

Kavya HM, Bavan S, Yogesha B et al (2021) Effect of coir fiber and inorganic filler on physical and mechanical properties of epoxy based hybrid composites. Polym Compos 42:3911–3921. https://doi.org/10.1002/pc.26103

Hoque MB, Hossain MS, Nahid AM et al (2018) Fabrication and Characterization of Pineapple Fiber-Reinforced Polypropylene Based Composites. Nano Hybrids Compos 21:31–42. https://doi.org/10.4028/www.scientific.net/nhc.21.31

Natrayan L, Kumar PVA, Baskara Sethupathy S et al (2022) Water Retention Behaviour and Fracture Toughness of Coir/Pineapple Leaf Fibre with Addition of Al2O3Hybrid Composites under Ambient Conditions. Adsorpt Sci Technol. 2022. https://doi.org/10.1155/2022/7209761

Siengchin S (2012) Impact, thermal and mechanical properties of high density polyethylene/flax/SiO 2 composites: Effect of flax reinforcing structures. J Reinf Plast Compos 31:959–966. https://doi.org/10.1177/0731684412451333

Velmurugan G, Babu K, Nagaraj M, Kumar AJP (2023) Investigations of Flame Retardancy, Mechanical and Thermal Properties of Woven Hemp/PP Hybrid Composite for Insulating Material Reinforced with Synthetic Silicon and Zinc Oxides. Silicon. https://doi.org/10.1007/s12633-023-02408-4

Hamid NH, Hisan WSIWB, Abdullah UH et al (2019) Mechanical properties and moisture absorption of epoxy composites mixed with amorphous and crystalline silica from rice husk. BioResources 14:7363–7374. https://doi.org/10.15376/biores.14.3.7363-7374

Lakshmaiya N, Ganesan V, Paramasivam P, Dhanasekaran S (2022) Influence of Biosynthesized Nanoparticles Addition and Fibre Content on the Mechanical and Moisture Absorption Behaviour of Natural Fibre Composite. Appl Sci (Switzerland). 12. https://doi.org/10.3390/app122413030

Maurya AK, Gogoi R, Manik G (2021) Mechano-chemically activated fly-ash and sisal fiber reinforced PP hybrid composite with enhanced mechanical properties. Cellulose 28:8493–8508. https://doi.org/10.1007/s10570-021-03995-4

Sormunen P, Kärki T (2019) Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J Build Eng 24:100742. https://doi.org/10.1016/j.jobe.2019.100742

Sitticharoen W, Chainawakul A, Sangkas T, Kuntham Y (2016) Rheological and mechanical properties of silica-based bagasse-fiber-ash-reinforced recycled HDPE composites. Mech Compos Mater 52:421–432. https://doi.org/10.1007/s11029-016-9594-z

Velmurugan G, Natrayan L, Rao YS et al (2022) Influence of Epoxy/Nanosilica on Mechanical Performance of Hemp/Kevlar Fiber Reinforced Hybrid Composite with an Ultrasonic Frequency. Adsorpt Sci Technol 2022:1–11. https://doi.org/10.1155/2022/7233255

Pan M, Mei C, Du J, Li G (2014) Synergistic effect of nano silicon dioxide and ammonium polyphosphate on flame retardancy of wood fiber-polyethylene composites. Compos A Appl Sci Manuf 66:128–134. https://doi.org/10.1016/j.compositesa.2014.07.016

Lakshmaiya N, Kaliappan S, Patil PP et al (2022) Influence of Oil Palm Nano Filler on Interlaminar Shear and Dynamic Mechanical Properties of Flax/Epoxy-Based Hybrid Nanocomposites under Cryogenic Condition. Coatings 12. https://doi.org/10.3390/coatings12111675

Haris NIN, Hassan MZ, Ilyas RA et al (2022) Dynamic mechanical properties of natural fiber reinforced hybrid polymer composites: a review. J Market Res 19:167–182. https://doi.org/10.1016/j.jmrt.2022.04.155

Natrayan L, Kumar PVA, Kaliappan S et al (2022) Optimisation of Graphene Nanofiller Addition on the Mechanical and Adsorption Properties of Woven Banana/Polyester Hybrid Nanocomposites by Grey-Taguchi Method. Adsorpt Sci Technol. 2022. https://doi.org/10.1155/2022/1856828

Velmurugan G, Natrayan L (2023) Experimental investigations of moisture diffusion and mechanical properties of interply rearrangement of glass/Kevlar-based hybrid composites under cryogenic environment. J Market Res 23:4513–4526. https://doi.org/10.1016/j.jmrt.2023.02.089

Siva Shankar V, Natrayan L et al (2022) Multiresponse Optimization of Mechanical and Physical Adsorption Properties of Activated Natural Fibers Hybrid Composites. Adsorpt Sci Technol 2022:1–16. https://doi.org/10.1155/2022/1384738

Acknowledgements

The authors thank Saveetha School of Engineering, SIMATS, Chennai, Tamil Nadu for the technical assistance.

Author information

Authors and Affiliations

Contributions

Velmurugan G: Conceptualization, Writing an original draft, Methodology.

Siva Shankar V and Kalil Rahiman M: Investigation.

Nagaraj M, Elil Raja D and Nagalakshmi T J: Testing and Evaluation.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Yes. All permission granted.

Compliance with Ethical Standards

Yes.

Competing Interests

The authors declare no competing interests.

Conflicts of Interest

Nil.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

G, V., V, S. ., M, K. . et al. Experimental Investigation of High Filler Loading of SiO2 on the Mechanical and Dynamic Mechanical Analysis of Natural PALF fibre-Based Hybrid Composite. Silicon 15, 5587–5602 (2023). https://doi.org/10.1007/s12633-023-02464-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02464-w