Abstract

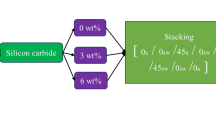

Hybrid polymer composites have become the interest of the world, especially in mechanical and electronic applications. Recently, advanced machining techniques such as abrasive water jet machining of hybrid polymer composites have been used to solve many problems including the ability to form complex shapes, high performance, better surface features, and high levels of accuracy. In this study, the effect of ceramic particle (SiC and Al2O3) constituents on the mechanical properties and machinability of the hybrid polymer composites was investigated. The results of mechanical tests showed that an improvement in the tensile and flexural properties appeared using a hybrid polymer constituent (70 wt% Epoxy + 15 wt% CF + 10 wt% Sic + 5 wt% Al2O3). However, this hybrid polymer constituent includes the lowest value of impact strength. Also, the morphological analysis indicated the uniform distribution of particles, the best defect-free surface, and the bonding strength between the reinforcement and the epoxy matrix can be obtained using this constituent which has contributed to the improvement of the mechanical properties. The abrasive water jet automation process was also performed based on the design of experiment (Taguchi L18 design) to study the machinability the hybrid polymer composites in terms of surface roughness, hardness, and kerf width. The analysis of variance concluded that the constituent (70 wt% Epoxy + 15 wt% CF + 10 wt% Sic + 5 wt% Al2O3) has the most influential factor on the machinability of the hybrid polymer composite followed by traverse velocity, and then stand of distance that used during abrasive water jet machining. Moreover, the grey relational analysis was beneficially used to determine the multi-optimization of abrasive water jet machining parameters.

Similar content being viewed by others

Data Availability

The authors declare that data and related material not been published elsewhere nor is it under consideration in any other journal.

References

Khoramishad H, Mousavi MV (2019) Hybrid polymer composite materials. AIP Conf Proc. 2144. https://doi.org/10.1063/1.5123100

Koniuszewska AG, Kaczmar JW (2016) Application of polymer based composite materials in transportation. Prog Rubber Plast Recycl Technol. 32(1):1–23. https://doi.org/10.1177/147776061603200101

Chavhan GR, Wankhade LN (2020) Improvement of the mechanical properties of hybrid composites prepared by fibers, fiber-metals, and nano-filler particles-A review. Mater Today Proc 27(1):72–82. https://doi.org/10.1016/j.matpr.2019.08.240

Vara Prasad G, Nagappa S, Ravi Kanth Y, Gopi Lakshmi I, BabuRao J (2020) Effect of brachyura shell particles on glass fibre reinforced epoxy polymer composite. Mater Today Proc 42:555–562. https://doi.org/10.1016/j.matpr.2020.10.521

Bhattacharjee A, Roy H (2020) Assessment of tensile and damping behaviour of hybrid particle/woven fibre/polymer composites. Compos Struct 244(October 2019):112231. https://doi.org/10.1016/j.compstruct.2020.112231

Sinha R, Sengupta S, Jayapalan S (2022) Effect of hybrid fillers on the mechanical behavior of polypropylene based hybrid composites. J Indian Chem Soc 99(2):100317

Premnath AA (2019) Drilling studies on carbon fiber-reinforced nano-SiC particles composites using response surface methodology. Part Sci Technol 37(4):474–482. https://doi.org/10.1080/02726351.2017.1398795

Khashaba UA, Aljinaidi AA, Hamed MA (2015) Development of CFRE composite scarf adhesive joints with SiC and Al<inf>2</inf>O<inf>3</inf> nanoparticle. Compos Struct 128:415–427. https://doi.org/10.1016/j.compstruct.2015.03.071

Sen D, Nayak C, Sudhakar KG, Birla S (2021) Mechanical properties of fabricated hybrid composites infused with Heat-Treated alkali sisal fiber and SiC particles: a quantitative analysis. Polym Bull 78(8):4629–4648. https://doi.org/10.1007/s00289-020-03329-7

Harikumar R, Devaraju A (2020) Evaluation of mechanical properties of bamboo fiber composite with addition of Al2O3 nano particles. Mater Today Proc 39:606–609. https://doi.org/10.1016/j.matpr.2020.08.613

Sathees Kumar S, Kanagaraj G (2016) Investigation of Characterization and Mechanical Performances of Al2O3 and SiC Reinforced PA6 Hybrid Composites. J Inorg Organomet Polym Mater 26(4):788–798. https://doi.org/10.1007/s10904-016-0387-6

Suresha B, Adappa K, Subramani NK (2018) Mechanical and tribological behaviours of epoxy hybrid composites reinforced by carbon fibers and silicon carbide whiskers. Mater Today Proc 5(8):16658–16668. https://doi.org/10.1016/j.matpr.2018.06.027

Thakur RK, Singh KK (2020) Experimental investigation and optimization of abrasive water jet machining parameter on multi-walled carbon nanotube doped epoxy/carbon laminate. Meas J Int Meas Confed 164:108093. https://doi.org/10.1016/j.measurement.2020.108093

Jesthi DK, Nayak RK, Nanda BK, Das D (2019) Assessment of abrasive jet machining of carbon and glass fiber reinforced polymer hybrid composites. Mater Today Proc 18:3116–3121. https://doi.org/10.1016/j.matpr.2019.07.185

Jagadeesh B, Dinesh Babu P, Nalla Mohamed M, Marimuthu P (2018) Experimental investigation and optimization of abrasive water jet cutting parameters for the improvement of cut quality in carbon fiber reinforced plastic laminates. J Ind Text 48(1):178–200. https://doi.org/10.1177/1528083717725911

Prasad KS, Chaitanya G (2020) Experimental study on surface roughness and dimensional accuracy of hole machining process on GFRP composites using abrasive water jet technique. Mater Today Proc 23(3):651–658. https://doi.org/10.1016/j.matpr.2019.05.463

Jesthi DK, Nayak RK (2020) Sensitivity analysis of abrasive air-jet machining parameters on machinability of carbon and glass fiber reinforced hybrid composites. Mater. Today Commun 25(August):101624. https://doi.org/10.1016/j.mtcomm.2020.101624

Thakur RK, Singh KK, Ramkumar J (2020) Delamination analysis and hole quality of hybrid FRP composite using abrasive water jet machining. Mater Today Proc 33(8):5653–5658. https://doi.org/10.1016/j.matpr.2020.04.056

Schwartzentruber J, Papini M, Spelt JK (2018) Characterizing and modelling delamination of carbon-fiber epoxy laminates during abrasive waterjet cutting. Compos Part A Appl Sci Manuf 112:299–314. https://doi.org/10.1016/j.compositesa.2018.06.014

Thongkaew K, Wang J, Li W (2019) An investigation of the hole machining processes on woven carbon-fiber reinforced polymers (CFRPs) using abrasive waterjets. Mach Sci Technol 23(1):19–38. https://doi.org/10.1080/10910344.2018.1449217

Prasad KS, Chaitanya G (2018) Selection of optimal process parameters by Taguchi method for Drilling GFRP composites using Abrasive Water jet machining Technique. Mater Today Proc 5(9):19714–19722. https://doi.org/10.1016/j.matpr.2018.06.333

Kavimani V, Gopal PM, Sumesh KR, Kumar NV (2020) Multi Response Optimization on Machinability of SiC Waste Fillers Reinforced Polymer Matrix Composite Using Taguchi’s Coupled Grey Relational Analysis. Silicon. https://doi.org/10.1007/s12633-020-00782-x

Selvam R, Arunkumar N, Karunamoorthy L (2020) An investigation on machining characteristics in abrasive water jet machining of hybrid laminated composites with SiC nano particles. Mater Today Proc 39(4):1701–1709. https://doi.org/10.1016/j.matpr.2020.06.193

Mullaikodi SM, Shanmugasundaram K, Rao VS, Rengarajan S (2019) Synthesis, characterization and machinability studies on thin hybrid composites with SiC nano particles. Mater Res Express 6(6). https://doi.org/10.1088/2053-1591/ab0ddc

Thakur RK, Singh KK (2020) Abrasive waterjet machining of fiber-reinforced composites: a state-of-the-art review. J Brazilian Soc Mech Sci Eng 42(7). https://doi.org/10.1007/s40430-020-02463-7

Thakur RK, Singh KK (2021) Evaluation of advanced machining processes performance on filler-loaded polymeric composites: a state-of-the-art review. J Brazilian Soc Mech Sci Eng 43(6):1–13. https://doi.org/10.1007/s40430-021-03027-z

Thakur RK, Singh KK (2021) Influence of fillers on polymeric composite during conventional machining processes: a review. J Brazilian Soc Mech Sci Eng 43(2):1–20. https://doi.org/10.1007/s40430-021-02813-z

Kamaraj M, Dodson EA, Datta S (2020) Effect of graphene on the properties of flax fabric reinforced epoxy composites. Adv Compos Mater 29(5):443–458. https://doi.org/10.1080/09243046.2019.1709679

Vaggar GB, Kamate SC, Badyankal PV (2019) A study on thermal conductivity enhancement of silicon carbide filler glass fiber epoxy resin hybrid composites. Mater Today Proc 35(3):330–334. https://doi.org/10.1016/j.matpr.2020.02.008

Rajamuneeswaran S, Vairamuthu J, Nagarajan S, Stalin B, Jayabal S (2020) A comparative study on mechanical properties of coir fiber reinforced polymer composites filled with calcium carbonate particles. Mater Today Proc 33(7):4790–4792. https://doi.org/10.1016/j.matpr.2020.08.366

Slebi-Acevedo CJ, Silva-Rojas IM, Lastra-González P, Pascual-Muñoz P, Castro-Fresno D (2020) Multiple-response optimization of open graded friction course reinforced with fibers through CRITIC-WASPAS based on Taguchi methodology. Constr Build Mater 233:117274. https://doi.org/10.1016/j.conbuildmat.2019.117274

Hoseinpour-Lonbar M, Alavi MZ, Palassi M (2020) Selection of asphalt mix with optimal fracture properties at intermediate temperature using Taguchi method for design of experiment. Constr Build Mater 262:120601. https://doi.org/10.1016/j.conbuildmat.2020.120601

Zhang F, Wang M, Yang M (2021) Successful application of the Taguchi method to simulated soil erosion experiments at the slope scale under various conditions. Catena 196(July 2020):104835. https://doi.org/10.1016/j.catena.2020.104835

Chenrayan V et al (2022) An experimental and empirical assessment of machining damage of hybrid glass-carbon FRP composite during abrasive water jet machining. J Mater Res Technol 19:1148–1161. https://doi.org/10.1016/j.jmrt.2022.05.042

Goel P, Khan ZA, Siddiquee AN, Kamaruddin S, Gupta RK (2012) Influence of slab milling process parameters on surface integrity of HSLA: A multi-performance characteristics optimization. Int J Adv Manuf Technol 61(9–12):859–871. https://doi.org/10.1007/s00170-011-3763-y

Kumar U, Singh M, Singh S (2021) Wire-Electrochemical Discharge Machining of SiC Reinforced Z-Pinned Polymer Matrix Composite Using Grey Relational Analysis. Silicon 13(3):777–786. https://doi.org/10.1007/s12633-020-00484-4

Agarwal G, Patnaik A, Sharma RK (2013) Thermo-mechanical properties of silicon carbide filled chopped glass fiber reinforced epoxy composites. Int J Adv Struct Eng 5(1):1–8. https://doi.org/10.1186/2008-6695-5-21

Antil P, Singh S, Manna A (2018) Glass fibers/SiCp reinforced epoxy composites: Effect of environmental conditions. J Compos Mater 52(9):1253–1264. https://doi.org/10.1177/0021998317723448

Abu-Okail M et al (2021) Effect of dispersion of alumina nanoparticles and graphene nanoplatelets on microstructural and mechanical characteristics of hybrid carbon/glass fibers reinforced polymer composite. J Mater Res Technol 14:2624–2637. https://doi.org/10.1016/j.jmrt.2021.07.158

Rana RS, Buddi T, Purohit R (2021) Effect of SiC reinforcement on the mechanical properties of Kevlar fiber based hybrid epoxy composites. Mater Today Proc 44:2478–2481. https://doi.org/10.1016/j.matpr.2020.12.542

Chethanbabu HM, Ramachandra M (2019) Evaluation of mechanical properties of polypropylene fibre reinforced epoxy composite filled with silicon carbide particulates. Mater Today Proc 46(10):4400–4406. https://doi.org/10.1016/j.matpr.2020.09.669

Soni S, Rana RS, Singh B, Rana S (2018) Synthesis and Characterization of Epoxy based Hybrid Composite Reinforced with Glass Fiber and Milled Carbon. Mater Today Proc 5(2):4050–4058. https://doi.org/10.1016/j.matpr.2017.11.666

Selvam R, Karunamoorthy L, Arunkumar N (2017) Investigation on performance of abrasive water jet in machining hybrid composites. Mater Manuf Process 32(6):700–706. https://doi.org/10.1080/10426914.2016.1198039

Hu D, Tang CL, Kang Y, Li X (2016) An investigation on cutting quality by adding polymer in abrasive water jet. Part Sci Technol 34(3):352–358. https://doi.org/10.1080/02726351.2015.1082522

Krajcarz D, Bańkowski D, Młynarczyk P (2017) The Effect of Traverse Speed on Kerf Width in AWJ Cutting of Ceramic Tiles. Procedia Eng 192(December):469–473. https://doi.org/10.1016/j.proeng.2017.06.081

Acknowledgements

Authors are grateful to the college of engineering, university of diyala, Iraq for extending the facilities for conduction of the research work

Author information

Authors and Affiliations

Contributions

Noor Hassan Ali: Writing- Original draft preparation, Investigation, Software, Methodology, Prepared figures and tables, Suha K. Shihab: Supervision, Visualization, Conceptualization, Data curation, Software, Validation, Writing- Reviewing and Editing. Muzher T. Mohamed: Supervision.

Corresponding author

Ethics declarations

Ethics Approval

All authors declare that all the ethical standards required for the preparation and publication have been complied with. The manuscript has not been published elsewhere nor is it under consideration in any other journal.

Consent to Participate

The authors have given their consent for participation.

Consent for Publication

All authors of this paper consent for publishing manuscript, tables and figures in this journal.

Competing Interests

The authors declare that they have no competing of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ali, N.H., Shihab, S.K. & Mohamed, M.T. Influence of Ceramic Particles Additives on the Mechanical Properties and Machinability of Carbon Fiber/Polymer Composites. Silicon 15, 5485–5502 (2023). https://doi.org/10.1007/s12633-023-02449-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02449-9