Abstract

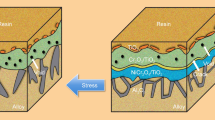

This work presents the numerical investigation of manufacturing the multi-crystalline silicon (mc-Si) ingots by using a lab-scale directional solidification furnace. Thermal distribution, melt-crystal interface and power consumption are investigated. The heat extraction from the crystal plays an important role in the growth of the better quality ingot. The modification was done on the heat exchanger block (HEB). In this modified furnace, 1/3rd part of the HEB is replaced by the insulation block and the dimensions of the modified HEB are 90 mm* 240 mm. The purpose of the modification is to reduce heat extraction in the peripheral region during the growth process. The modified furnace and conventional furnace results are compared. In the overall growth process, the modified furnace maintained the convex melt-crystal interface due to heat extracted from the bottom of the crucible. The main advantage of the modified furnace is consuming less power compared to the conventional furnace which saves 87 kW of power. These results reduce thermal stress and maintained the convex melt-crystal interface during the growth process.

Similar content being viewed by others

Data Availability

Not Applicable.

Code Availability

Not Applicable.

References

Li TF, Huang HC, Tsai HW, Lan A, Chuck C, Lan CW (2012) An enhanced cooling design in directional solidification for high quality multi-crystalline solar silicon. J Cryst Growth 340(1):202–208

Nagarajan SG, Srinivasan M, Aravinth K, Ramasamy P (2018) Influence of additional heat exchanger block on directional solidification system for growing multi-crystalline silicon ingot–A simulation investigation. In AIP Conference Proceedings (Vol. 1942, No. 1, pp 140061). AIP Publishing LLC

Lan CW, Lan WC, Lee TF, Yu A, Yang YM, Hsu WC, … Yang A (2012). Grain control in directional solidification of photovoltaic silicon. J Cryst Growth 360:68–75

Nguyen THT, Liao SH, Chen JC, Chen CH, Huang YH, Yang CJ, … Nguyen HB (2016) Effects of the hot zone design during the growth of large size multi-crystalline silicon ingots by the seeded directional solidification process. J Cryst Growth 452:27–34

Ma X, Zheng L, Zhang H, Zhao B, Wang C, Xu F (2011) Thermal system design and optimization of an industrial silicon directional solidification system. J Cryst Growth 318(1):288–292

Su W, Li J, Yang W, Han X, Guan Z, Zhang Z (2022) Numerical investigation of bottom grille for improving large-size silicon quality in directional solidification process. Silicon 14(1):211–221

Kesavan V, Srinivasan M, Ramasamy P (2019) Optimization of heat transfer properties of the directional solidification furnace by modifying heat exchanger blocks. Mater Res Express 6(11):115921

Hu C, Chen JC, Nguyen THT, Hou ZZ, Chen CH, Huang YH, Yang M (2018) Optimization of heat transfer during the directional solidification process of 1600 kg silicon feedstock. J Cryst Growth 484:70–77

Zhou J, Ren Y, Cao Y, Duan J, Feng T, Liu W (2021) Effect of hot zone design on polycrystalline silicon ingot growth process by seeded directional solidification. Silicon 13(2):523–530

Yu Q, Liu L, Ma W, Zhong G, Huang X (2012) Local design of the hot-zone in an industrial seeded directional solidification furnace for quasi-single crystalline silicon ingots. J Cryst Growth 358:5–11

Liu L, Yu Q, Qi X, Zhao W, Zhong G (2015) Controlling solidification front shape and thermal stress in growing quasi-single-crystal silicon ingots: Process design for seeded directional solidification. Appl Therm Eng 91:225–233

Ma W, Zhong G, Sun L, Yu Q, Huang X, Liu L (2012) Influence of an insulation partition on a seeded directional solidification process for quasi-single crystalline silicon ingot for high-efficiency solar cells. Sol Energy Mater Sol Cells 100:231–238

Teng YY, Chen JC, Lu CW, Chen CY (2010) The carbon distribution in multicrystalline silicon ingots grown using the directional solidification process. J Cryst Growth 312(8):1282–1290

Yang X, Ma W, Lv G, Wei K, Luo T, Chen D (2014) A modified vacuum directional solidification system of multicrystalline silicon based on optimizing for heat transfer. J Cryst Growth 400:7–14

Li Z, Liu L, Liu X, Zhang Y, Xiong J (2014) Heat transfer in an industrial directional solidification furnace with multi-heaters for silicon ingots. J Cryst Growth 385:9–15

Wu Z, Zhong G, Zhang Z, Zhou X, Wang Z, Huang X (2015) Optimization of the high-performance multi-crystalline silicon solidification process by insulation partition design using transient global simulations. J Cryst Growth 426:110–116

Lukanin DP, Kalaev VV, Makarov YN, Wetzel T, Virbulis J, Von Ammon W (2004) Advances in the simulation of heat transfer and prediction of the melt-crystal interface shape in silicon CZ growth. J Cryst Growth 266(1–3):20–27

Peng Y, Feng T, Zhou J (2022) Effect of power ratio of side/top heaters on the performance and growth of multi-crystalline silicon ingots. Mater Lett 306:130968

Daggolu P, Ryu JW, Galyukov A, Kondratyev A (2016) Analysis of the effect of symmetric/asymmetric CUSP magnetic fields on melt/crystal interface during Czochralski silicon growth. J Cryst Growth 452:22–26

Sanmugavel S, Srinivasan M, Aravinth K, Ramasamy P (2016) Numerical investigations on hot-zone modified DS furnace for mc-Si growth process. In AIP Conference Proceedings (Vol. 1731, No. 1, pp 110033). AIP Publishing LLC

Smirnova OV, Mamedov VM, Kalaev VV (2014) Cryst Growth Des 14:5532

CGSim Theory manual, Version 16.1, STR Group, Inc.

Keerthivasan T, Chen CJ, Sugunraj S, Srinivasan M, Ramasamy P (2022) Influence of radiation heat transfer on Mc-Si ingot during directional solidification: a numerical investigation. Silicon 1–10

Gurusamy A, Manickam S, Karuppanan A, Perumalsamy R (2018) Simulation studies of annealing effect on a mc-Si ingot for photovoltaic application. SILICON 10(3):1021–1033

Dutta PS (2010) Bulk crystal growth of ternary III–V semiconductors. Springer Handbook of Crystal Growth, pp 281–325

Sugunraj S, Aravindan G, Srinivasan M, Ramasamy P (2022) Influence of argon gas flow rate on oxygen and carbon impurities concentration in multicrystalline silicon grown by directional solidification furnace: numerical and experimental investigation. Silicon 1–24

Nguyen TH, Thu J-C, Chieh Hu, Chen C-H, Huang Y-H, Lin H-W, Andy Yu, Hsu B (2017) Numerical analysis of thermal stress and dislocation density distributions in large size multi-crystalline silicon ingots during the seeded growth process. J Cryst Growth 468:316–320

Funding

This work is supported by the Department of Science and Technology, Government of India (Order No. DST/TMD/CERI/RES/2020/7 dated 31/12/2020).

Author information

Authors and Affiliations

Contributions

Sugunraj Sekar—Writing—Original Draft.

Aravindan Gurusamy—Formal Analysis—Investigation.

Srinivasan Manikkam—Supervision.

Ramasamy Perumalsamy—Review & Editing.

Corresponding author

Ethics declarations

This study involving human participants were in accordance with the ethical standards of the institutional and/or national research committee.

Consent to Participate

Informed consent was obtained from all individual participants included in the study.

Consent for Publication

Consent for publication was obtained from all individual participants included in the study.

Competing Interests

The authors declare no competing interests.

Conflicts of Interest

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sekar, S., Gurusamy, A., Manikkam, S. et al. Improvement of DS Grown Mc-Si Ingot for PV Application by Reducing the Thickness of the Bottom Heat Exchanger Block: Numerical Investigation. Silicon 15, 4183–4192 (2023). https://doi.org/10.1007/s12633-023-02350-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02350-5