Abstract

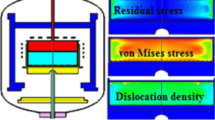

The temperature field distribution during the growth of crystalline silicon by the directional solidification (DS) method is an important factor affecting the growth rate, the shape of the melt-crystal (m-c) interface, and thermal stress. To solve the problem of m-c interface convexity at the early stage of crystal growth caused by supercooling at the bottom center of silicon ingot during DS. In this paper, a two dimensional (2D) global transient numerical model based on a large-size ALD-G7 (G7) crystalline silicon ingot furnace is established and experimentally verified. Based on the model, the influence of different bottom thermal gate moving process curves on the convexity of the m-c interface at the early stage was studied, with emphasis on the changes in temperature field, m-c interface, and thermal stress at the early stage of crystal growth. We have designed three cases, case 1 uses the original moving process curve of bottom thermal gate, case 2 and case 3 adjust the process curve to 0.95 and 0.9 of the original ratio, respectively. The numerical simulation results show that compared with case 1, the average heat dissipation at the bottom of the silicon ingot in case 2 and case 3 is reduced by 2.7 kW·m−2 and 4 kW·m−2, and the maximum thermal stress is also reduced by 3 MPa and 4 MPa, separately. The maximum convexity of the interface is reduced by 25 mm and 20 mm, and the convexity is reduced by 55% and 44% on average, respectively.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this article.

References

Lan C, Lan A, Yang C, Hsu H, Yang M, Yu A, Hsu B, Hsu W, Yang A (2017) The emergence of high-performance multi-crystalline silicon in photovoltaics. J Cryst Growth 468:17–23. https://doi.org/10.1016/j.jcrysgro.2016.10.072

Verband Deutscher Maschinen- und Anlagenbau. International Technology Roadmap for Photovoltaic [EB/OL]. https://www.vdma.org/international-technology-roadmap-photovoltaic. Accessed 2021

Fujiwara K, Chuang L, Maeda K (2022) Dynamics at crystal/melt interface during solidification of multicrystalline silicon. High Temp Mater Processes 41(1):31–47. https://doi.org/10.1515/htmp-2022-0020

Schwanke S, Trempa M, Reimann C, Kuczynski M, Schroll G, Sans J, Friedrich J (2019) Production of high performance multi-crystalline silicon ingots for PV application by using contamination-free SixNy seed particles. J Cryst Growth 522:151–159

Dai J, Yang Y, Hsu C, Tseng H, Wang P, Yang C (2021) Simulation analysis of silicon ingot growth in directional solidification system. 33(8): 2577-2589. https://doi.org/10.1016/j.jcrysgro.2019.05.030

Rao S, Chen X, Zhang F, He L, Luo Y, Xiong H, Hu Y, Wang F, Song B (2020) Influence of modified bottom insulation on the seeded directional solidification process for high-performance multi-crystalline silicon. Vacuum 172:108969

Su W, Han X, Chang C, Zhang Z, Zhang Z, Yang W, Li J, Wang J (2021) Impact of seed orientation on dislocation propagation in cast seed-assisted monocrystalline silicon. Sol Energy Mater Sol Cells 230:111084. https://doi.org/10.1016/j.vacuum.2019.108969

Gurusamy A, Manickam S, Perumalsamy R (2022) Quality improvement of multi-crystalline silicon ingot by the hot-zone modification. J Cryst Growth 592:126720. https://doi.org/10.1016/j.jcrysgro.2022.126720

Zhang Z, Yu X, Yuan S, Yang D (2021) Experimental study of 3D solid-liquid interfaces and their influence on directional solidification silicon ingot. Sol Energy Mater Sol Cells 224:110991. https://doi.org/10.1016/j.solmat.2021.110991

Trempa M, Kranert C, Kupka I, Reimann C, Friedrich J (2019) Evaluation of improvement strategies of grain structure properties in high performance multi-crystalline silicon ingots. J Cryst Growth 514:114–123. https://doi.org/10.1016/j.jcrysgro.2019.03.005

Nagarajan S, Sanmugavel S, Kesavan V, Aravindan G, Srinivasan M, Ramasamy P (2019) Influence of additional insulation block on multi-crystalline silicon ingot growth process for PV applications. J Cryst Growth 516:10–16. https://doi.org/10.1016/j.jcrysgro.2019.03.017

Nagarajan S, Anbu G, Srinivasan M, Aravinth K, Ramasamy P (2019) Simulation analysis of direction solidification process with fixed partition block to grow multi crystalline silicon ingot. Silicon 11(1):401–406. https://doi.org/10.1007/s12633-018-9851-y

Anbu G, Nagarajan S, Aravindan G, Srinivasan M, Ramasamy P (2021) Influence of additional insulation block on melt-crystal interface shape in directional solidification system for growing high quality mc-silicon ingot: a simulation investigation. Silicon 13(6):1713–1722. https://doi.org/10.1007/s12633-020-00572-5

Fang H, Wang S, Zhou L, Zhou N, Lin M (2012) Influence of furnace design on the thermal stress during directional solidification of multicrystalline silicon. J Cryst Growth 346(1):5–11. https://doi.org/10.1016/j.jcrysgro.2012.02.032

Ma X, Zheng L, Zhang H, Zhao B, Wang C, Xu F (2011) Thermal system design and optimization of an industrial silicon directional solidification system. J Cryst Growth 318(1):288–292. https://doi.org/10.1016/j.jcrysgro.2010.10.102

Nagarajan S, Srinivasan M, Aravinth K, Ramasamy P (2019) Improving heat transfer properties of DS furnace by the geometrical modifications for enhancing the multi crystalline silicon ingot (mc-Si) quality using transient simulation. Silicon 11(2):603–613. https://doi.org/10.1007/s12633-018-9870-8

Anbu G, Thiyagarajan M, Aravindan G, Srinivasan M, Ramasamy P (2022) Investigation of DS furnace heat exchange block thickness for the improvement mc-Si ingot quality. Silicon. https://doi.org/10.1007/s12633-022-02162-z

Zhang Z, Yu X, Yang D (2022) A new Design of Side Heater for 3D solid-liquid Interface improvement in G8 directional solidification silicon ingot growth. Silicon. https://doi.org/10.1007/s12633-022-01701-y

Kesavan V, Srinivasan M, Ramasamy P (2019) The influence of multiple-heaters on the reduction of impurities in mc-Si for directional solidification. Silicon 11(3):1335–1344. https://doi.org/10.1007/s12633-018-9928-7

Anbu G, Srinivasan M, Ramasamy P (2019) Modelling on modified heater design of DS system for improving the quality of mc-silicon ingot. Silicon 11(3):1393–1400. https://doi.org/10.1007/s12633-018-9944-7

Rao S, He L, Zhang F, Lei Q, Luo Y, Xiong H, Hu Y, Huang X, Song B (2020) Numerical and experimental investigation of sectional heater for improving multi-crystalline silicon ingot quality for solar cells. J Cryst Growth 537:125606. https://doi.org/10.1016/j.jcrysgro.2020.125606

Vizman D, Friedrich J, Mueller G (2007) 3D time-dependent numerical study of the influence of the melt flow on the interface shape in a silicon ingot casting process. J Cryst Growth 303(1):231–235. https://doi.org/10.1016/j.jcrysgro.2006.11.317

Miyazawa H, Liu L, Hisamatsu S, Kakimoto K (2008) Numerical analysis of the influence of tilt of crucibles on interface shape and fields of temperature and velocity in the unidirectional solidification process. J Cryst Growth 310(6):1034–1039. https://doi.org/10.1016/j.jcrysgro.2007.12.021

Karuppasamy P, Srinivasan M, Aravinth K, Ramasamy P (2018) Numerical modelling on modified directional solidification process of multi-crystalline silicon growth for photovoltaic applications. Mater Today: Proc 5(11):23014–23021. https://doi.org/10.1016/j.matpr.2018.11.030

Su W, Li J, Yang W, Han X, Guan Z, Zhang Z (2021) Numerical investigation of bottom grille for improving large-size silicon quality in directional solidification process. Silicon. https://doi.org/10.1007/s12633-021-01159-4

Chen W, Wu Z, Zhong G, Ding J, Yu Y, Zhou X, Huang X (2016) Optimization of heat transfer by adjusting power ratios between top and side heaters for casting high-performance multi-crystalline silicon ingots. J Cryst Growth 451:155–160. https://doi.org/10.1016/j.jcrysgro.2016.07.031

Li Z, Liu L, Liu X, Zhang Y, Xiong J (2012) Effects of argon flow on melt convection and interface shape in a directional solidification process for an industrial-size solar silicon ingot. J Cryst Growth 360:87–91. https://doi.org/10.1016/j.jcrysgro.2011.11.053

Song B, Luo Y, Rao S, Zhang F, Hu Y (2020) Numerical simulation on Design of Temperature Control for side heater in directional solidification system of multi-crystalline silicon. Silicon 12(9):2179–2187. https://doi.org/10.1007/s12633-019-00310-6

Hu C, Chen J, Nguyen T, Hou Z, Chen C, Huang Y, Yang M (2018) Optimization of heat transfer during the directional solidification process of 1600 kg silicon feedstock. J Cryst Growth 484:70–77. https://doi.org/10.1016/j.jcrysgro.2017.12.042

Qiu S, Wen S, Fang M, Zhang L, Gan C, Jiang D, Tan Y, Li J, Luo X (2016) Process parameters influence on the growth rate during silicon purification by vacuum directional solidification. Vacuum 125:40–47. https://doi.org/10.1016/j.vacuum.2015.11.024

Aravindan G, Srinivasan M, Aravinth K, Ramasamy P (2019) Numerical study on effect of side insulation movement in the multi-crystalline silicon growth process. Silicon 11(3):1327–1333. https://doi.org/10.1007/s12633-018-9927-8

Sundaramahalingam S, Gurusamy A, Perumalsamy R (2022) Transient simulation on the growth of mono-like silicon ingot in DS process using crucible with Plano-concave bottom for PV applications. Silicon 14(7):3653–3663. https://doi.org/10.1007/s12633-021-01144-x

Xi Y, Ma W, Lv G, Wei K, Luo T, Chen D (2014) A modified vacuum directional solidification system of multicrystalline silicon based on optimizing for heat transfer. J Cryst Growth 400:7–14. https://doi.org/10.1016/j.jcrysgro.2014.04.025

Keerthivasan T, Aravindan G, Srinivasan M, Ramasamy P Effect of partial replacement of retort with an insulation material on mc-silicon grown in directional solidification furnace: numerical modeling. Silicon. https://doi.org/10.1007/s12633-021-01538-x

Su W, Li J, Yang W, Han X, Guan Z, Zhang Z (2021) Numerical investigation of bottom grille for improving large-size silicon quality in directional solidification process. Silicon 14(1):211–221. https://doi.org/10.1007/s12633-021-01159-4

Zhou J, Ren Y, Cao Y, Duan J, Feng T, Liu W (2021) Effect of hot zone design on polycrystalline silicon ingot growth process by seeded directional solidification. Silicon 13(2):523–530. https://doi.org/10.1007/s12633-020-00450-0

Qi X, Zhao W, Liu L, Yang Y, Zhong G, Huang X (2014) Optimization via simulation of a seeded directional solidification process for quasi-single crystalline silicon ingots by insulation partition design. J Cryst Growth 398:5–12. https://doi.org/10.1016/j.jcrysgro.2014.04.011

Wu Z, Zhong G, Zhou X, Zhang Z, Wang Z, Chen W, Huang X (2016) Upgrade of the hot zone for large-size high-performance multi-crystalline silicon ingot casting. J Cryst Growth 441:58–63. https://doi.org/10.1016/j.jcrysgro.2016.02.012

Su W, Yang W, Li J, Han X, Wang J (2021) Numerical study of the upgraded hot zone in silicon directional solidification process. Cryst Res Technol 56(2):6. https://doi.org/10.1002/crat.202000180

Su W, Li C, Qi X, Yang W, Wang J (2019) Numerical analysis and optimization of gas flow and impurity control in directional solidification multi-crystalline Si. J Cryst Growth 527:125244. https://doi.org/10.1016/j.jcrysgro.2019.125244

Su W, Li J, Li C, Yang W, Wang J (2022) Design and numerical optimization of gas guidance system in casting silicon furnace by the orthogonal experiment. Silicon 14(1):301–307. https://doi.org/10.1007/s12633-021-01192-3

Chen X, Nakano S, Liu L, Kakimoto K (2008) Study on thermal stress in a silicon ingot during a unidirectional solidification process. J Cryst Growth 310(19):4330–4335. https://doi.org/10.1016/j.jcrysgro.2008.07.027

Funding

The Project is supported by Key Research and Development Program of Jiangsu Province of China (Grant No. BE2019009-003), Industry-University-Research Project (Wuxi Suntech Solar Power Co., Ltd. Grant No. 8421130025). The National Natural Science Foundation for Young Scholars of China (Grant No. 51206069).

Author information

Authors and Affiliations

Contributions

Wenjia Su contributed to the conception of the study. Zhicheng Guan and Jiulong Li performed the simulation and contributed significantly to analysis and manuscript written. Zhen Zhang performed the data analyses and modified the manuscript. Jiaqi Li helped perform the analysis with constructive discussion.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Yes. All permission granted.

Consent for Publication

The authors agree to publish.

Competing Interests

The authors declare no competing interests.

Conflict of Interest

There are no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, W., Guan, Z., Li, J. et al. Numerical Investigation on the Effect of Thermal Gate Moving Rate on Directional Solidification Process. Silicon 15, 3103–3112 (2023). https://doi.org/10.1007/s12633-022-02235-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02235-z