Abstract

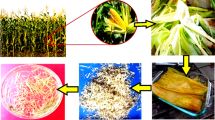

In this present research cellulose rich corn husk fibre and corn cob biosilica particles are used to make high toughness epoxy bio-composites for low cost and light weighted technological applications. The goal of this work was to determine how a silane-alkali treated corn husk fiber and corn cob biosilica particles introduced at various concentrations affects the mechanical and thermal properties, as well as tribologyof an epoxy based composite. The composites with alkali-silane-treated corn husk fiber and 1 vol.% of biosilica had a highest tensile, flexural strength and impact toughness of about 184 MPa, 212 MPa, 6.82 J revealing that the inclusion of corn husk fibre and corn cob biosilica as a reinforcing material is beneficial. The biocomposite also possesses lower specific wear rate and coefficient of friction for the addition of 2 vol.% biosilica particle for specific wear rate and COF about 0.008 mm3/Nm and 0.38, respectively. Furthermore, the composites exhibit good thermal properties having Tg of 1020C by addition of 30 vol. % fiber and 2.0 vol. % biosilica particles. These epoxy biocomposites with improved mechanical and thermal properties, as well as good wear characteristics, could be beneficial in various engineering applications requiring high load bearing capacity and biodegradability.

Similar content being viewed by others

Data Availability

No data available to deposit as private. There is no rights.

References

Alshahrani H, Arun Prakash VR (2022) Thermal, mechanical and barrier properties of rice husk ash biosilica toughened epoxy biocomposite coating for structural application. Prog Org Coat 172:107080

Alshahrani H, Arun Prakash VR (2022) Mechanical, fatigue and DMA behaviour of high content cellulosic corn husk fibre and orange peel biochar epoxy biocomposite: a greener material for cleaner production. J Clean Prod 374:133931. https://doi.org/10.1016/j.jclepro.2022.133931

V R AP et al (2020) Effect of silicon coupling grafted ferric oxide and e-glass fibre in thermal stability, wear and tensile fatigue behaviour of epoxy hybrid composite. Silicon 12:2533–2544. https://doi.org/10.1007/s12633-019-00347-7

Vincent VA, Kailasanathan C, Shanmuganathan VK et al (2022) Strength characterization of caryota urens fibre and aluminium 2024–T3 foil multi-stacking sequenced SiC-toughened epoxy structural composite. Biomass Conv Bioref 12:4009–4019. https://doi.org/10.1007/s13399-020-00831-w

Ben Samuel J, JulyesJaisingh S, Sivakumar K et al (2021) Visco-elastic, thermal, antimicrobial and dielectric behaviour of areca fibre-reinforced nano-silica and neem oil-toughened epoxy resin bio composite. Silicon 13:1703–1712. https://doi.org/10.1007/s12633-020-00569-0

Sun X, Agate S, Salem KS, Lucia L, Pal L (2021) ACS Appl Bio Mater 4 (1): 140-162. https://doi.org/10.1021/acsabm.0c01011

Parthipan N, Ilangkumaran M, Maridurai T, Prasanna SC (2020) Effect of Silane treated silicon (IV) oxide nanoparticle addition on mechanical, impact damage and drilling characteristics of kenaf fibre-reinforced epoxy composite. Silicon 12:459–467

Thiyagu TT, J.V SPK, P G et al (2021) Effect of cashew shell biomass synthesized cardanol oil green compatibilizer on flexibility, barrier, thermal, and wettability of PLA/PBAT biocomposite films. Biomass Conv. Bioref. https://doi.org/10.1007/s13399-021-01941-9

Singh H, Chatterjee A (2021) Effect of filler loading and orientation on alkali-treated cornhusk film reinforced epoxy laminate composites. Indian J Fibre Text Res 46:275–286

Naik P et al (2021) Abrasive wear behaviour of orange peel (biowaste) particulate reinforced polymer composites. Proc Inst Mech Eng Part J J Eng Tribol 235.10:2099–2109

Hanish Anand S et al (2022) Optimization of aging, coating temperature and reinforcement ratio on biosilica toughened in-situ Al-TiB2 metal matrix composite: a Taguchi grey relational approach. Silicon 14(8):4337–4347

Daramola OO et al (2018) Effect of Guinea corn husk ash on the mechanical properties and wear behaviour of epoxy matrix composites. Int J Civ Eng Technol (IJCIET) 9(11):1207–1216

Singh H, Chatterjee A (2020) Potential of alkali treated cornhusk film as reinforcement for epoxy laminate composites. Cellulose 27:2555–2567. https://doi.org/10.1007/s10570-019-02917-9

Ibrahim MIJ et al (2019) Potential of using multiscale corn husk fiber as reinforcing filler in cornstarch-based biocomposites. Int J Biol Macromol 139:596–604

Anand SH, Venkateshwaran N (2021) Effect of heat treatment and biosilica on mechanical, wear, and fatigue behavior of Al-TiB2 in situ metal matrix composite. Biomass Conv Bioref: 1–13. https://doi.org/10.1007/s13399-021-01402-3

Keerthiveettil Ramakrishnan Sumesh et al (2022) The effect of various composite and operating parameters in wear properties of epoxy-based natural fiber composites. J Mater Cycles Waste Manag 242:667–679. https://doi.org/10.1007/s10163-022-01357-1

Ravikumar P et al (2022) Delamination and surface roughness analysis of jute/polyester composites using response surface methodology: consequence of sodium bicarbonate treatment. J Ind Textiles: 15280837221077040. https://doi.org/10.1177/15280837221077040

Vincent VA, Kailasanathan C, Shanmuganathan VK et al (2022) Strength characterization of caryota urens fibre and aluminium 2024–T3 foil multi-stacking sequenced SiC-toughened epoxy structural composite. Biomass Conv Bioref 12:4009–4019. https://doi.org/10.1007/s13399-020-00831-w

Sumesh KR et al (2022) The influence of different parameters in tribological characteristics of pineapple/sisal/TiO2 filler incorporation. J Ind Textiles 51.5:8626S-8644S

Ganesh S et al (2022) Investigation on the mechanical properties of ramie/kenaf fibers under various parameters using GRA and TOPSIS methods. Polym Compos 43.1:130–143

Paul R, Gouda K, Bhowmik S (2021) Effect of different constraint on tribological behaviour of natural fibre/filler reinforced polymeric composites: a review. Silicon 13(8):2785–2807

Kumar SMS, Duraibabu D, Subramanian K (2014) Studies on mechanical, thermal and dynamic mechanical properties of untreated (raw) and treated coconut sheath fiber reinforced epoxy composites. Mater Des 59:63–69

Balaji A, Purushothaman R, Udhayasankar R et al (2020) Study on mechanical, thermal and morphological properties of banana fiber-reinforced epoxy composites. J Bio Tribo Corros 6:60. https://doi.org/10.1007/s40735-020-00357-8

Mohit H, Sanjay MR, Siengchin S et al (2021) Effect of TiC nanoparticles reinforcement in Coir fiber based bio/synthetic epoxy hybrid composites: mechanical and thermal characteristics. J Polym Environ 29:2609–2627. https://doi.org/10.1007/s10924-021-02069-7

Sumesh KR, Kanthavel K (2019) Green synthesis of aluminium oxide nanoparticles and its applications in mechanical and thermal stability of hybrid natural composites. J Polym Environ 27:2189–2200. https://doi.org/10.1007/s10924-019-01506-y

Siakeng R et al (2021) Flexural and dynamic mechanical properties of alkali-treated coir/pineapple leaf fibres reinforced polylactic acid hybrid biocomposites. J Bionic Eng 18.6:1430–1438

Srivastava KR et al (2019) Pretreatment of banana pseudostem fibre for green composite packaging film preparation with polyvinyl alcohol. J Polymer Res 26.4:1–11. https://doi.org/10.1007/s10965-019-1751-3

Mahalingam S, Babu AS (2022) Characterization of 3-aminopropyltriethoxysilane treated stacked silicate nanoclay and red Matta-RHA biosilica woven ramie fibre epoxy composite. Silicon 14:8129–8139. https://doi.org/10.1007/s12633-021-01549-8

Karthigairajan M, Nagarajan PK, RavirajaMalarvannan R et al (2021) Effect of silane-treated rice husk derived biosilica on visco-elastic, thermal conductivity and hydrophobicity behavior of epoxy biocomposite coating for air-duct application. Silicon 13:4421–4430. https://doi.org/10.1007/s12633-020-00772-z

Rajadurai A (2017) Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Defence Technol 13.1:40–46

Demchuk Z et al (2022) Unravelling the influence of surface modification on the ultimate performance of carbon fiber/epoxy composites. ACS Appl Mater Interfaces 14,40:45775–45787. https://doi.org/10.1021/acsami.2c11281

Alshahrani H et al (2022) Effect of palmyra sprout fiber and biosilica on mechanical, wear, thermal and hydrophobic behavior of epoxy resin composite. J Ind Textiles 52:15280837221137382

Behera U, Das SK, Mishra DP, Parhi PK, Das D (2021) ACS Omega 6 (35): 22820-22830. https://doi.org/10.1021/acsomega.1c03241

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Alshahrani H et al (2022) Mechanical Properties study on sandwich composites of Glass Fiber Reinforced Plastics (GFRP) using liquid thermoplastic resin, elium®: preliminary experiments. Coatings 12.10:1423

Prakash VRA, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos A: Appl Sci Manuf 118:317–326

Dharmavarapu P, Reddy MBSS (2021) Mechanical, low velocity impact, fatigue and tribology behaviour of silane grafted aramid fibre and nano-silica toughened epoxy composite. Silicon 13:1741–1750. https://doi.org/10.1007/s12633-020-00567-2

Alshahrani H, Prakash VRA (2022) Effect of silane-grafted orange peel biochar and areca fibre on mechanical, thermal conductivity and dielectric properties of epoxy resin composites. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02801-w

Gümüş BE, Yağci Ö, Taşdemir M (2022) High-density polyethylene/artichoke leaf powder polymer composites: dynamic mechanical, morphological and thermal properties. Iran Polym J 31:787–797. https://doi.org/10.1007/s13726-022-01031-1

Muthalagu R, Srinivasan V, Sathees Kumar S et al (2021) Extraction and effects of mechanical characterization and thermal attributes of jute, prosopis juliflora bark and kenaf fibers reinforced bio composites used for engineering applications. Fibers Polym 22:2018–2026. https://doi.org/10.1007/s12221-021-1092-9

Das PP, Chaudhary V (2022) Tribological properties of biofiber-based polymer composites. In: Advances in bio-based fiber. Woodhead Publishing, pp 193–211

Egala R, Jagadeesh GV, Setti SG (2021) Experimental investigation and prediction of tribological behavior of unidirectional short castor oil fiber reinforced epoxy composites. Friction 9:250–272. https://doi.org/10.1007/s40544-019-0332-0

Jayabalakrishnan D et al (2021) Mechanical, dielectric, and hydrophobicity behavior of coconut shell biochar toughened Caryota urens natural fiber reinforced epoxy composite. Polym Compos 43:493–502. https://doi.org/10.1002/pc.26393

Prabhu P et al (2022) Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Conv Bioref: 1–8. https://doi.org/10.1007/s13399-021-02177-3

Alshahrani H, VR AP (2022) Mechanical, wear, and fatigue behavior of alkali-silane-treated areca fiber, RHA biochar, and cardanol oil-toughened epoxy biocomposite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02691-y

Author information

Authors and Affiliations

Contributions

All have done equal contribution.

Corresponding author

Ethics declarations

Compliance with ethical standards

Yes this article compliance with ethical standards of journal.

Consent to Participate

Yes. All permission granted.

Consent for Publication

Yes. All permission granted.

Conflicts of Interest/Competing Interests

There is no conflict of interest by any form for this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

P, M., K, S.V. Experimental Investigations of Epoxy Biocomposites Developed Using Alkali-Silane treated Cellulosic Corn Husk Fiber and Corn Cob Biosilica. Silicon 15, 2941–2951 (2023). https://doi.org/10.1007/s12633-022-02227-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02227-z