Abstract

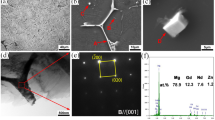

The investigation aims to study the microstructure and mechanical property changes of various silicon added WE43 alloys. With the increase in Si addition, the Mg2Si phase forms randomly in grains apart from the formed neodymium and yttrium rich phases like Mg24Y5 and Mg41Nd5. The morphology of the eutectic Mg2Si phase changes to a tiny needle shape on 0.5% addition of silicon and upon 1%, it again transforms to a Chinese script phase when the addition increases above 1%, along with the formed eutectic Mg2Si phase, polygonal primary Mg2Si phase. Simultaneously, a new intermetallic was developed based on the quantity of silicon addition; at lower silicon addition, it’s a star-shaped compound and in higher addition, rare earth silicon intermetallic phase was formed, which is confirmed through scanning electron microscopy analyses. The hardness of WE43 alloy varies from 77 to 97 BHN; the YS (162 MPa), UTS (196 MPa) and % E (4.94%) gradually decline as silicon addition exceeds 1%. Silicon minimizes dislocations and strain flow locations, whereas the improved characteristics are likely due to solid solution strengthening and grain refinement.

Similar content being viewed by others

Data Availability

All the original data are available with the corresponding author.

Code Availability

Not applicable.

References

Zhang J, Liu S, Wu R, Hou L, Zhang M (2018). J Magnes Alloy 6:277–291

Mezbahul-Islam M, Mostafa AO, Medraj M (2014). J Mater 33. https://doi.org/10.1155/2014/704283

Lyu S, Xiao W, Zheng R, Wang F, Hu T, Ma C (2018). Mater Sci Eng A. https://doi.org/10.1016/j.msea.2018.06.085

Ma C, Peng G, Nie L, Liu H, Guan Y (2018). Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2018.03.174

Xie J, Zhang J, Zihao Y, Lui S, Guan K, Wu R, Wang J, Feng J (2021) J Magnes Alloy 9:41–56

Smithstegen K (2015). Energy Policy 79:1–8

Marazza R, Riani P, Cacciamani G (2008). Inorganica Chim Acta 361:3800–3806

Byrne RH, Biqiong L (1995). Geochimicaet Cosmochimica Acta 59(22):4575–4589

Hampl M, Blawert C, Campos MRS, Hort N, Peng Q, Kainer KU, Schmid-Fetzer R (2013). J Alloys Compd 581:166–177

Okamoto H (1993). J Phase Equilib 14:257–259

Ghorbanpoura S, Brandon A, McWilliams MK (2019). Mater Sci Eng A 747:27–41

Yamada K, Okubo Y, Shiono M, Watanabe H, Kamado S, Kojima Y (2006). Mater Trans 47:1066–1070

Chou D, Hong D, Saha P, Ferrero J, Lee B, Tan Z, Dong Z, Kumta PN (2013). Acta Biomater 9:8518–8533

Su ZJ, Liu CM, Wang YC, Shu X (2013). Mater Sci Technol 29:148–155

Anyanwu IA, Kamado S, Kojina Y (2001). Mater Trans 412:1206–1211

Aghion E, Levy G, Ovadia S (2012). J Mater Sci Mater Med 23:805–812. https://doi.org/10.1007/s10856-011-4536-8

Luo K, Zhang L, Wu G, Liu W, Ding W (2019). J Magnes Alloy 7:345–354

Sudholz AD, Gusieva K, Chen XB, Muddle BC, Gibson MA, Birbilis N (2011). Corros Sci 53:2277–2282

Rokhlin LL, Nikitina NI (1998). J Alloys Compd 279:166–170

Kumar KKA, Pillai UTS, Pai BC, Chakraborty M (2013). Met Mater Int 19:1167–1172

Mordike BL, Ebert T (2001). Mater Sci Eng A 302:37–45

X. Xu, X. Chen, W. Du, Y.Geng, F. Pan. https://doi.org/10.1016/j.jmst.2017.04.011

Meier JM, Caris J, Luo AA (2022). J Magnes Alloy 10:1401–1427

Sun Q, Cheng H, Mei X, Liu Y, Li G, Xu Q, Lu X (2020). Sci Rep. https://doi.org/10.1038/s41598-020-66894-x

Yanova EAL, Rokhlin LL, Dobatkina TV, Korol’kova IG (2012). Russ Metall 7:625–629

Kaya A, Hamu GB, Eliezer D, Shin KS, Kohen S (2006). Met Sci Heat Treat No 11:46–50

Feyerabend F, Fischer J, Holtz J, Witte F, Willumeit R, Drucker H, Vogt C, Hort N (2010). Acta Biomater 6:1834–1842

Sasha P, Viswanathan S (2011). AFS Proceedings 11:1–11

Jiang HS, Zheng MY, Qiao XG, Wu K, Peng QY, Yang SH, Yuan YH, Luo JH (2016). Mater Sci Eng A 684:158–164

Chen Q, Xia X, Yuan B, Shu D, Zhao Z, Han J (2014). Mater Sci Eng A 593:38–47

Ninlachart J, Karmiol Z, Chidambaram D, Raja KS (2017). J Magnes Alloy 2:147–165

Xiang C, Gupta N, Coelho P, Cho K (2018). Mater Sci Eng A 710:74–85

Jie LZ, Hua WUG, Cai LW, Song P, Jiang DW (2012). Trans Nonferrous Met Soc China 22:1540–1548

Mabuchi M, Higashi K (1996). Acta Mater 44:4611–4618

Zhang X, Li YJ, Zhang K, Wang CS, Li HW, Ma ML, Zhang BD (2013). Trans Nonferrous Met Soc China 23:1226–1236

Rzychon T, Kielbus A (2007). J Achiev Mater Manuf Eng 684:158–164

Pereira GS, Koga GY, Avila JA, Bittencourt IM, Fernandez F, Miyazaki MH, Botta WJ, Filho WWB (2021). Mater Chem Phys 272:124930

Esmaily M, Zeng Z, Mortazavi AN, Gullino A, Choudhary S, Derra T, Benn F, D’Elia F, Muther M, Thomas S, Huang A, Allanore A, Kopp A, Birbilis N. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101321

Yan XY, Zhang F, Chang YA (2000). J Phase Equilib 21:379–384

Kumar KKA, Pillai UTS, Pai BC, Chakraborty M (2012). Mater Sci For 710:401–406

Sundararaju G, Thangadurai KR, Charman CA, Kumar KKA (2021). Silicon. https://doi.org/10.1007/s12633-021-01255-5

Kumar KKA, Srinivasan A, Pillai UTS, Pai BC, Chakraborty M (2022). Silicon. https://doi.org/10.1007/s12633-021-01521-6

Acknowledgements

The authors are indebted to the casting and characterization tests like optical microstructure, hardness and tensile testing by MatRICS – Materials Research and Innovation Centric Solutions, Vellimalai, Kanyakumari District, 629 204, INDIA, Tel: +91 91766 06699; web: www.matricstech.com.

Author information

Authors and Affiliations

Contributions

S. Muthu Kumar, K.K. Ajith Kumar and J.Godwin contributed to the design and implementation of the research and writing the manuscript.

Corresponding author

Ethics declarations

Research Involving Human Participants and/ or Animals

Not Applicable.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Publishers can publish images and results there are no restrictions.

Conflict of Interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muthukumar, S., Ajith Kumar, K.K. & Godwin, J. Influence of Silicon Addition on the Microstructure and Mechanical Properties of WE43 Alloy. Silicon 15, 1535–1544 (2023). https://doi.org/10.1007/s12633-022-02166-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02166-9