Abstract

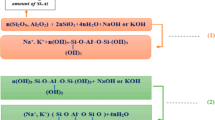

Manufacturing of ordinary Portland cement is an energy intensive process that emits harmful greenhouse gases in the atmosphere which pollutes the environment. With the surge in infrastructural activities across the world consumption of the concrete is also expected to increase thereby increasing the OPC production. On the other hand, under-utilization of fly ash from thermal power plants compare to its generation has created environmental and disposal problem. Utilization of fly ash based geopolymer concrete in place of Portland cement concrete presents a suitable remedy to the environmental and land disposal problems. Also, geopolymer concrete have less carbon footprint compared to Portland cement concrete. This paper presents a comprehensive review of composition, mix design methods, production process, curing regimes, benefits, limitation, and applications of fly ash based geopolymer concrete. It reports most notable research findings on properties of fresh and hardened state geopolymer concrete over past decade. Lastly, it determines key factors to be considered for selecting appropriate curing regime for achieving required performance of concrete. Compilation of such extensive volume of information may provide a valuable insight for future research.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Malhotra VM (2002) Introduction: sustainable development and concrete technology. ACI Concr Int 24:22

Hardjito D, Wallah SE, Sumajouw DM, Rangan BV (2004) On the development of fly ash-based geopolymer concrete. Mater J 101:467–472

Harris D, Heidrich C, Feuerborn J (2019) Global aspects on coal combustion products. In: World of Coal Ash Conference, Conference Paper

Haque ME (2013) Indian fly-ash: production and consumption scenario. Int J Waste Resour 3:22–25

Surabhi S (2017) Fly ash in India: generation vis-à-vis utilization and Global perspective. Int J Appl Chem 13:29–52

Report on fly ash generation at coal/Lignite based thermal power stations and its utilization in the country for year 2019-20 (Nov 2020) Central Electricity Authority, New Delhi. http://www.cea.nic.in/reports/others/thermal/tcd/flyash_2019-20.pdf. Accessed 02 Feb 2021

Rastogi A, Paul VK (2020) A critical review of the potential for fly ash utilisation in construction-specific applications in India. Env Res Eng Manag 76:65–75

Davidovits J (1989) Geopolymers and geopolymeric materials. J Therm Anal 35:429–441

Meesala CR, Verma NK, Kumar S (2020) Critical review on fly-ash based geopolymer concrete. Struct Concr 21:1013–1028

Agrawal US, Wanjari SP, Naresh DN (2019) Impact of replacement of natural river sand with geopolymer fly ash sand on hardened properties of concrete. Const Build Mater 209:499–507

Malhotra VM (1999) In: Parameswaran VS (eds) International Conference on Fibre Composites, High-Performance Concrete and Smart Materials, Chennai, India

McCaffrey R (2002) Climate change and the cement industry. GCL: Envir Sp Issu 8:15–19. https://thegreencaiman.files.wordpress.com/2016/03/climate_change_and_the_cement_industry.pdf

Agrawal US, Wanjari SP, Naresh DN (2017) Characteristic study of geopolymer fly ash sand as a replacement to natural river sand. Const Build Mater 150:681–688

Mathew BJ, Sudhakar M, Natarajan C (2013) Strength, economic and sustainability characteristics of coal ash–GGBS based geopolymer concrete. Int J Comput Eng Res 3:207–212

Risdanareni P, Ekaputri JJ, Abdullah Al Bakri MM (2015) Effect of alkaline activator ratio to mechanical properties of geopolymer concrete with trass as filler. Appl Mech Mater 754:406–412

Temuujin J, Van Riessen A, MacKenzie KJD (2010) Preparation and characterisation of fly ash based geopolymer mortars. Const Build Mater 24:1906–1910

Headwaters Resources (2005) Fly ash types& benefits. Utah, USA. http://www.flyash.com/data/upimages/press/TB.1%20Fly%20Ash%20-%20Types%20&%20Benefits.pdf

Thomas M (2007) Optimizing the use of fly ash in concrete. Portland Cement Association, Skokie, vol 5420, p 24

Ekaputri JJ, Bahrul UM, Bayuaji R, Eddy ST, Mustafa M, Bakri A, Ash F (2015) A comprehensive characterization and determination of fly ashes in indonesia using different methods. Appl Mech Mater 754:320–325

Das SK, Mohapatra AK, Rath AK (2014) Geo-polymer concrete – Green concrete for the future — A review. Int J Civ Eng Res 5:21–28

Al Bakri MM, Mohammed H, Kamarudin H, Niza IK, Zarina Y (2011) Review on fly ash-based geopolymer concrete without portland cement. J Eng Technol Res 3(1):1–4

Ryu GS, Lee YB, Koh KT, Chung YS (2013) The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Const Build Mater 47:409–418

Joseph B, Mathew G (2012) Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Scientia Iranica 19:1188–1194

Isabella C, Xu H, Luckey GC, Van Deventer JSJ (2003) In: Mistry V, Azizinamini A, Hooks JM (eds). The effect of aggregate particle size on formation of geopolymeric gel. In: Advanced Materials Proceedings, Davos, Switzerland. https://dc.engconfintl.org/advanced_materials/9/

Ma CK, Awang AZ, Omar W (2018) Structural and material performance of geopolymer concrete: A review. Const Build Mater 186:90–102

Zerfu K, Ekaputri JJ (2016) Review on alkali-activated fly ash based geopolymer concrete. Mater Sci For 841:162–169

Shah MV, Kammula R, Nannapaneni P, Raijiwala PDB (2014) Alkali activated flyash based geopolymer concrete. J Artic 3:159–166

Nematollahi B, Sanjayan J (2014) Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater Des 57:667–672

Li N, Zhang Z, Shi C, Zhang J (2018) In: Alengram UJ, Hung MK, Jumaat MZ, Sulong NHR, Raman SN (eds) Some progresses in the challenges for geopolymer. IOP Conference Series: Material Science and Engineering, Malaysia

Montes C, Gomez SA, Khadka N, Allouche EN (2013) Statistical software to improve the accuracy of geopolymer concrete mix design and proportioning. Proceedings of 2013 world of coal ash conference, Lexington, Kentucky, USA, 22–25 April 2013. American Coal Ash Association, Farmington Hills, Michigan, USA. http://www.flyash.info/2013/123-Montes-2013.pdf

Li N, Shi C, Zhang Z, Wang H, Liu Y (2019) A review on mixture design methods for geopolymer concrete. Compos Part B Eng 178:107490

Xie T, Visintin P, Zhao X, Gravina R (2020) Mix design and mechanical properties of geopolymer and alkali activated concrete: Review of the state-of-the-art and the development of a new unified approach. Constr Build Mater 256:119380

Rangan B (2007) Concrete construction engineering handbook. CRC Press, Boca Raton

Diaz-Loya EI, Allouche EN, Vaidya S (2011) Mechanical properties of fly-ash-based geopolymer concrete. ACI Mater J 108:300

Diaz EI, Allouche EN, Eklund S (2010) Factors affecting the suitability of fly ash as source material for geopolymers. Fuel 89:992–996

Junaid MT, Narong T, Pichai N (2006) Reducing bleeding in mix for bored pile application without affecting other fresh concrete properties: methodology and procedure. In: Proceedings of the tenth East Asia-Pacific conference on structural engineering and construction. Bangkok, Thailand

Nawy EG (2008) Concrete construction engineering handbook. CRC Press, Boca Raton

Lloyd N, Rangan V (2010) In: Zachar J, Claisse P, Naik TR, Ganjian E (eds) Geopolymer concrete with fly ash. ASCE, Italy

Kong DL, Sanjayan JG (2008) Damage behavior of geopolymer composites exposed to elevated temperatures. Cem Conc Comp 30:986–991

Li N, Shi C, Wang Q, Zhang Z, Ou Z (2017) Composition design and performance of alkali-activated cements. Mater Struct 50:178

Aughenbaugh KL, Williamson T, Juenger MCG (2015) Critical evaluation of strength prediction methods for alkali-activated fly ash. Mater Struc 48:607–620

RSN 336-84 (1984) Republican building norms for production and use of slag alkaline binders, concretes and structures. The National Committee Ukrainian Republic of the USSR for construction, Kiev, USSR

Rangan BV (2008) Design and manufacture of flyash-based geopolymer concrete. Conc Aust 34:37–43

Anuradha R, Sreevidya V, Venkatasubramani R, Rangan BV (2012) Modified guidelines for geopolymer concrete mix design using Indian standard. Asian J Civ Eng (Build Hous) 13:353–364

Ferdous MW, Kayali O, Khennane A (2013) A detailed procedure of mix design for fly ash based geopolymer concrete. In: Proceedings of the fourth Asia-Pacific conference on FRP in structures. Melbourne, Australia https://researchbank.swinburne.edu.au/file/552b44c9-7cb9-4509-8229-ec0f1f9bba0c/1/PDF%20%28Published%20version%29.pdf

Ferdous W, Manalo A, Khennane A, Kayali O (2015) Geopolymer concrete-filled pultruded composite beams–concrete mix design and application. Cem Conc Comp 58:1–13

Pavithra PE, Reddy MS, Dinakar P, Rao BH, Satpathy BK, Mohanty AN (2016) A mix design procedure for geopolymer concrete with fly ash. J Clean Prod 133:117–125

Li N, Shi C, Zhang Z, Zhu D, Hwang HJ, Zhu Y, Sun T (2018) A mixture proportioning method for the development of performance-based alkali-activated slag-based concrete. Cem Conc Comp 93:163–174

Bondar D, Nanukuttan S, Provis JL, Soutsos M (2019) Efficient mix design of alkali activated slag concretes based on packing fraction of ingredients and paste thickness. J Clean Prod 218:438–449

Bellum RR, Nerella R, Madduru SRC, Indukuri CSR (2019) Mix design and mechanical properties of fly ash and GGBFS-synthesized Alkali-Activated Concrete (AAC). Infrastructures 4:20

Rao GM, Kumar KS, Poloju KK, Srinivasu K (2020) In: Kumar SV, Jena SP, Vardhan MV (eds) An emphasis of geopolymer concrete with single activator and conventional concrete with recycled aggregate and data analyzing using artificial neural network. IOP Conference Series: Materials Science and Engineering, India

Longos A, Tigue AA, Dollente IJ, Malenab RA, Bernardo-Arugay I, Hinode H, Kurniawan W, Promentilla MA (2020) Optimization of the mix formulation of geopolymer using nickel-laterite mine waste and coal fly ash. Mine 10:1144

Bondar D, Ma Q, Soutsos M, Basheer M, Provis JL, Nanukuttan S (2018) Alkali activated slag concretes designed for a desired slump, strength and chloride diffusivity. Const Build Mater 190:191–199

Türkmen İ, Gül R, Çelik C (2008) A Taguchi approach for investigation of some physical properties of concrete produced from mineral admixtures. Build Env 43:1127–1137

Hadi MN, Farhan NA, Sheikh MN (2017) Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Const Build Mater 140:424–431

Mehta A, Siddique R, Singh BP, Aggoun S, Łagód G, Barnat-Hunek D (2017) Influence of various parameters on strength and absorption properties of fly ash based geopolymer concrete designed by Taguchi method. Const Build Mater 150:817–824

Zain MFM, Abd SM (2009) Multiple regression model for compressive strength prediction of high performance concrete. J App Sci 9:155–160

Lokuge W, Wilson A, Gunasekara C, Law DW, Setunge S (2018) Design of fly ash geopolymer concrete mix proportions using Multivariate Adaptive Regression Spline model. Const Build Mater 166:472–481

Hadi MN, Zhang H, Parkinson S (2019) Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J Build Eng 23:301–313

Dao DV, Ly HB, Trinh SH, Le TT, Pham BT (2019) Artificial intelligence approaches for prediction of compressive strength of geopolymer concrete. Mater 12:983

Ling Y, Wang K, Wang X, Li W (2019) Prediction of engineering properties of fly ash-based geopolymer using artificial neural networks. Neur Comp Appl 3:1–21

Gao Y, Xu J, Luo X, Zhu J, Nie L (2016) Experiment research on mix design and early mechanical performance of alkali-activated slag using response surface methodology (RSM). Ceram Int 42:11666–11673

Zahid M, Shafiq N, Isa MH, Gil L (2018) Statistical modeling and mix design optimization of fly ash based engineered geopolymer composite using response surface methodology. J Clean Prod 194:483–498

CEN/TR PD (2013) Principles of the equivalent durability procedure. CEN, Brussels, p 16563

El-Hassan H, Ismail N (2018) Effect of process parameters on the performance of fly ash/GGBS blended geopolymer composites. J Sustain Cem Based Mater 7:122–140

Khayat KH, Ghezal A, Hadriche MS (2000) Utility of statistical models in proportioning self-consolidating concrete. Mater Str 33:338–344

Cihan MT, Güner A, Yüzer N (2013) Response surfaces for compressive strength of concrete. Constr Build Mater 40:763–774

Aldahdooh MAA, Bunnori NM, Johari MM (2013) Evaluation of ultra-high-performance-fiber reinforced concrete binder content using the response surface method. Mater Des 52:957–965

Mohammed BS, Achara BE, Nuruddin MF, Yaw M, Zulkefli MZ (2017) Properties of nano-silica-modified self-compacting engineered cementitious composites. J Clean Prod 162:1225–1238

Joshi SV, Kadu MS (2012) Role of alkaline activator in development of eco-friendly fly ash based geo polymer concrete. Int J Environ Sci Dev 3:417

Motorwala A, Shah V, Kammula R, Nannapaneni P, Raijiwala DB (2013) Alkali activated fly-ash based geopolymer concrete. Int J Emerg Technol Adv Eng 3:159–166

Vijai K, Kumutha R, Vishnuram BG (2010) Effect of types of curing on strength of geopolymer concrete. Int J Phys Sci 5:1419–1423

Adam AA, Horianto (2014) The effect of temperature and duration of curing on the strength of fly ash based geopolymer mortar. Proc Eng 95:410–414

Patil AA, Chore HS, Dode PA (2014) Effect of curing condition on strength of geopolymer concrete. Adv Conc Const 2:029

Venkateswara Rao J, Srinivasa Rao K, Rambabu K (2019) Performance of heat and ambient cured geopolymer concrete exposed to acid attack. Proc Inst Civ Eng Const Mater 172:192–200

Karunanithi S, Anandan S (2014) Flexural toughness properties of reinforced steel fibre incorporated alkali activated slag concrete. Adv Civ Eng 4(3):1–12

Srinivasan K, Sivakumar A (2015) Chemical activation and curing regime of geopolymer concretes. Proc Inst Civ Eng Const Mater 168:24–34

Yewale VV, Shirsath MN, Hake SL (2016) Evaluation of efficient type of curing for geopolymer concrete. Int J New Technol Sci Eng 3:10–14

Azarsa P, Gupta R (2020) Comparative study involving effect of curing regime on elastic modulus of geopolymer concrete. Buildings 10:101

Kumaravel S (2014) Development of various curing effect of nominal strength Geopolymer concrete. J Eng Sci Technol Rev 7:116–119

Rao GM, Venu M (2020). In: Sunramaniam KVL, Khan AM (eds) Mix design methodology for fly ash and GGBS-based geopolymer concrete. Springer, Singapore

Chindaprasirt P, Rattanasak U, Taebuanhuad S (2013) Role of microwave radiation in curing the fly ash geopolymer. Adv Powder Technol 24:703–707

Hong S, Kim H (2019) Effects of microwave energy on fast compressive strength development of coal bottom ash-based geopolymers. Sci Rep 9:1–17

Kastiukas G, Ruan S, Liang S, Zhou X (2020) Development of precast geopolymer concrete via oven and microwave radiation curing with an environmental assessment. J Clean Prod 255:120290

Hardjito D, Wallah SE, Sumajouw DM, Rangan BV (2004) Factors influencing the compressive strength of fly ash-based geopolymer concrete. Civ Eng Dimens 6:88–93

Rangan BV, Wallah S, Sumajouw D, Hardjito D (2006) Heat-cured, low-calcium, fly ash-based geopolymer concrete. Ind Conc J 80:47–52

Memon FA, Nuruddin MF, Demie S, Shafiq N (2012) Effect of superplasticizer and extra water on workability and compressive strength of self-compacting geopolymer concrete. Res J Appl Sci Eng Technol 4:407–414

Sanni SH, Khadiranaikar RB (2012) Performance of geopolymer concrete under severe environmental conditions. Int J Civ Struct Eng 3:396–407

Nath P, Sarker PK (2015) Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem Conc Comp 55:205–214

Deb PS, Nath P, Sarker PK (2014) The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater Des 62:32–39

Yasir S, Iftekar G (2015) Study of properties of Fly ash based geopolymer concrete. Inter J of Eng Res 3(3):74–79 http://www.ijoer.in/3.1.15/Yasir%2074-79.pdf

Singhal D, Junaid MT, Jindal BB, Mehta A (2018) Mechanical and microstructural properties of fly ash based geopolymer concrete incorporating alccofine at ambient curing. Const Build Mater 180:298–307

Jamkar SS, Ghugal YM, Patankar SV (2013) Effect of fly ash fineness on workability and compressive strength of geopolymer concrete. The Ind Conc J 87:57–62

Gomaa E, Sargon S, Kashosi C, Gheni A, El Gawady MA (2020) Mechanical properties of high early strength class C fly ash-based alkali activated concrete. Trans Res Rec J Transp Res Board 2674:430–443

Hardjito D, Rangan BV (2005) Development and properties of low-calcium fly ash-based geopolymer concrete. Report, Curtin University of Technology, Perth

Olivia M, Nikraz H (2011) Strength and water penetrability of fly ash geopolymer conrete. J Eng Appl Sci 6:70–78

Shetty KK, Gopinatha N, Pandit P, Karkera J, Kiran Kumara SS (2015) Strength and shrinkage characteristics of geo-polymer concrete. Int J Earth Sci Eng 8:169–172

Abdullah MMAB, Hussin K, Bnhussain M, Ismail KN, Yahya Z, Abdul Razak R (2012) Fly ash-based geopolymer lightweight concrete using foaming agent. Int J Mol Sci 13(6):7186–7198

Omar AA, Al Bakri Abdullah MM, Hussin K, Khairul Nizar I (2013) Lightweight fly ash-based geopolymer concrete. Adv Mater Res 626:781–785

Khalil WI, Abbas WA, Nasser IF (2019) Dynamic modulus of elasticity of geopolymer lightweight aggregate concrete. In: IOP Conference Series: Materials Science and Engineering, Iraq

Top S, Vapur H, Altiner M, Kaya D, Ekicibil A (2020) Properties of fly ash-based lightweight geopolymer concrete prepared using pumice and expanded perlite as aggregates. J Mol Struct 1202:127236

Leung CK, Pheeraphan T (1995) Very high early strength of microwave cured concrete. Cem Conc Res 25:136–146

Palomo A, Grutzeck MW, Blanco MT (1999) Alkali-activated fly ashes: A cement for the future. Cem Conc Res 29:1323–1329

Ahmed MF, Nuruddin MF, Shafiq N (2011) Compressive strength and workability characteristics of low-calcium fly ash-based self-compacting geopolymer concrete. Int J Civ Env Eng 5:64–70

Duxson P, Lukey GC, Separovic F, Van Deventer JSJ (2005) Effect of alkali cations on aluminum incorporation in geopolymeric gels. Ind Eng Chem Res 44:832–839

Sagoe-Crentsil K, Weng L (2007) Dissolution processes, hydrolysis and condensation reactions during geopolymer synthesis: Part II. High Si/Al ratio systems. J Mater Sci 42:3007–3014

Weng L, Sagoe-Crentsil K (2007) Dissolution processes, hydrolysis and condensation reactions during geopolymer synthesis: Part I—Low Si/Al ratio systems. J Mater Sci 42:2997–3006

Hou Y, Wang D, Zhou W, Lu H, Wang L (2009) Effect of activator and curing mode on fly ash-based geopolymers. J Wuhan Univ Tech Mater Sci Ed 24:711

Panias D, Giannopoulou IP, Perraki T (2007) Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Coll Surf A: Phys Eng Asp 301:246–254

Fernández-Jiménez A, Palomo A (2005) Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem Conc Res 35:1984–1992

Jaydeep S, Chakravarthy BJ (2013) Study on fly ash based geo-polymer concrete using admixtures. Int J Eng Trends Technol 4:4614–4617

Chindaprasirt P, Chareerat T, Sirivivatnanon V (2007) Workability and strength of coarse high calcium fly ash geopolymer. Cem Concr Compos 29:224–229

Nagalia G, Park Y, Abolmaali A, Aswath P (2016) Compressive strength and microstructural properties of fly ash–based geopolymer concrete. J Mater Civ Eng 28:04016144

Van Dao D, Trinh SH (2020) In: Cuong H-M, Van Dao D, Benboudjema F, Sybil D, Huynh DVK, Tang AM (eds) Mechanical properties of fly ash based geopolymer concrete using only steel slag as aggregate. Springer, Singapore

Hardjasaputra H, Cornelia M, Gunawan Y, Surjaputra IV, Lie HA, Ng GP (2019) In: Lie HA, Garrecht H, Sharma A, Hardjasaputra H (eds) Study of mechanical properties of fly ash-based geopolymer concrete. In IOP Conference Series: Materials Science and Engineering, Germany

Ganesh AC, Muthukannan M (2019) In: Muthusamy R (eds) Experimental study on the behaviour of hybrid fiber reinforced geopolymer concrete under ambient curing condition. In IOP Conference Series: Materials Science and Engineering, India

Moradikhou AB, Esparham A, Avanaki MJ (2020) Physical & mechanical properties of fiber reinforced metakaolin-based geopolymer concrete. Constr Build Mater 251:118965

Nematollahi B, Sanjayan J, Chai JXH, Lu TM (2014) Properties of fresh and hardened glass fiber reinforced fly ash based geopolymer concrete. Key Eng Mater 594:629–633

Łach M, Hebdowska-Krupa M, Mierzwiński D, Korniejenko K (2019) In: Lach M (eds) Mechanical properties of geopolymers reinforced with carbon and aramid long fibers. In IOP Conference Series: Materials Science and Engineering, Uruguay

Sukmak P, De Silva P, Horpibulsuk S, Chindaprasirt P (2015) Sulfate resistance of clay-portland cement and clay high-calcium fly ash geopolymer. J of Mater in Civi Eng 27:04014158

Nguyen KT, Lee YH, Lee J, Ahn N (2013) Acid resistance and curing properties for green fly ash-geopolymer concrete. J Asian Archit Build Eng 12:317–322

Wallah E, Rangan BV (2006) Low-calcium fly ash-based geopolymer concrete: Long-term properties. Report, Curtin University of Technology, Perth

Rendell F, Jauberthie R, Grantham M (2002) Deteriorated concrete: Inspection and physicochemical analysis. Thomas Telford, Scotland

Bhutta MAR, Hussin WM, Azreen M, Tahir MM (2014) Sulphate resistance of geopolymer concrete prepared from blended waste fuel ash. J Mater Civ Eng 26:04014080

Wallah SE (2009) Drying shrinkage of heat-cured fly ash-based geopolymer concrete. Mod Appl Sci 3:14–21

Davidovits J (1999) In: Davidovits J (ed) Chemistry of geopolymeric systems terminology. Proceedings of International Conference on Geopolymers, France, p 1999. https://www.tib.eu/en/search/id/BLCP:CN057039461/Chemistry-of-Geopolymeric-Systems-Terminology-pp?cHash=e692c081d1b646aed83bdb4a07970e96

Davidovits J (2013) Geopolymer cement. A review. Geop Insti Tech Pap 21:1–11

Sakthidoss DD, Senniappan T (2020) A study on high strength geopolymer concrete with alumina-silica materials using manufacturing sand. Silicon 12:735–746

Zhao R, Yuan Y, Cheng Z, Wen T, Li J, Li F, Ma ZJ (2019) Freeze-thaw resistance of class F fly ash-based geopolymer concrete. Const Build Mater 222:474–483

Abdelmseeh VA, Jofriet JC, Negi SC, Hayward GL (2005) Corrosion of reinforced concrete specimens exposed to hydrogen sulphide and sodium sulphate. Agric Eng Int CIGR J 7:1–15

Kishan LJ, Radhakrishna (2013) Comparative study of cement concrete and Geopolymer masonry blocks. Int J of Res in Eng Tech:361–365. https://ijret.org/volumes/2013v02/i13/IJRET20130213068.pdf

Oyebisi S, Ede A, Olutoge F, Omole D (2020) Geopolymer concrete incorporating agro-industrial wastes: Effects on mechanical properties, microstructural behaviour and mineralogical phases. Const Build Mater 256:119390

Ostwal T, Chitawadagi MV (2014) Experimental investigations on strength, durability, sustainability and economic characteristics of geopolymer concrete blocks. Int J Res Eng Technol 3:115–122

Ojha A, Gupta L (2020) In: Chauhan A, Sehgal S (eds) Comparative study on mechanical properties of conventional and geo-polymer concrete with recycled coarse aggregate. Materials Today: Proceedings, Chandigarh, Punjab, India

Mathew BJ, Sudhakar M, Natarajan C (2013) Strength, economic and sustainability characteristics of coal ash–GGBS based geopolymer concrete. Int J Comp Eng Res 3:207–212

Sun P, Wu HC (2008) Transition from brittle to ductile behavior of fly ash using PVA fibers. Cem Conc Comp 30:29–36

Yunsheng Z, Wei S, Zongjin L, Xiangming Z, Chungkong C (2008) Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr Build Mater 22:370–383

Andrews-Phaedonos F (2014) Specification and use of geopolymer concrete. Austroads bridge conference, 9th, 2014, Sydney, New South Wales, Australia (no. 6.2). https://trid.trb.org/view/1341131

Goriparthi MR (2017) Effect of fly ash and GGBS combination on mechanical and durability properties of GPC. Adv Conc Const 5:313

Acknowledgements

The principal author acknowledges the contribution of co-author in preparing the manuscript.

Author information

Authors and Affiliations

Contributions

Literature search, data analysis and drafting are performed by principal author. Idea for the article and critical revision is provided by co-author.

Corresponding author

Ethics declarations

Conflicts of competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to participate

The author(s) declare that no humans or participants are involved in this study.

Consent for publication

The author(s) declare that the figures and tables used in this paper are original and are not published anywhere.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ojha, A., Aggarwal, P. Fly Ash Based Geopolymer Concrete: a Comprehensive Review. Silicon 14, 2453–2472 (2022). https://doi.org/10.1007/s12633-021-01044-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01044-0