Abstract

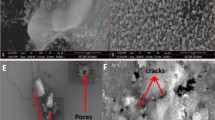

Titanium Nitride (TiN) thin films were deposited by thermal chemical vapor deposition process (CVD) over Si (100) substrate under different substrate temperatures. Morphological, mechanical, and structural properties were characterized by different techniques e.g. SEM, AFM, Nanoindentation and XRD. SEM images reveal the presence of agglomerated particles over the surface and AFM images reveal the enhancement of surface roughness with higher deposition temperature. The analysis of electrochemical polarization and electrochemical properties of TiN coatings reveals decrease in corrosion resistance with increase in process temperature. The nanoindentation analysis has confirmed that TiN coating possess maximum fracture toughness (KC), hardness (H), and Young’s modulus (Ef) when synthesized at the temperature of 1150 °C. For comparative study, an analysis over structural properties using different models e.g. UDM, UDEM, SSP etc. have been used in this study. The data analysis of TiN coatings are carried out by using Origin 9.0 software.

Similar content being viewed by others

References

Van Hove RP, Sierevelt IN, Van Royen BJ, Nolte PA (2015) Titanium-Nitride Coating of Orthopaedic Implants: A Review of the Literature. Biomed Res Int Article ID 485975

Mezger PR, Creugers NHJ (1992) Titanium nitride coatings in clinical dentistry. J Dent 20:342–344

Gotman I, Gutmanas EY (2014) Titanium nitride-based coatings on implantable medical devices. Adv Biom Devices Med 1:53–73

Pandey SK, Pandey SK, Awasthi V, Gupta M, Deshpande UP, Mukherjee S (2013) Influence of in-situ annealing ambient on p-type conduction in dual ion beam sputtered Sb-doped ZnO thin films. Appl Phys Lett 103:072109

Wolfe DE, Singh J (1999) Microstructural evolution of titanium nitride (TiN) coatings produced by reactive ion beam-assisted, electron beam physical vapor deposition (RIBA, EB-PVD). J Mater Sci 34:2997–3006

Shin YH, Shimogaki Y (2004) Chemical vapor deposition of TiAlN film by using titanium tetrachloride, Dimethylethylamine Alane and Ammonia gas for ULSI cu diffusion barrier application. Jap J App Phy 43:8253–8257

Musher JN, Gordon RG (1996) Atmospheric pressure chemical vapor deposition of titanium nitride from Tetrakis (diethylamido) titanium and Ammonia. J Electrochem Soc 143:736

Fix R, Gordon R, Hoffman D (1989) Titanium nitride thin films: properties and Apcvd synthesis using organometallic precursors. MRS Proc 168:357

Huang HH, Hon MH (2002) Effect of N2 addition on growth and properties of titanium nitride films obtained by atmospheric pressure chemical vapor deposition. Thin Solid Films 416:54–61

Halliday D, Resnick R, Krane KS (1992) Physics. John Wiley & Sons, New York

Sears FW, Zemansky MW, Young HD (1987) University physics. Addison–Wesley, London

Huang HH, Hon MH (2001) Effect of H2 addition on characteristics of TiN films deposited by APCVD. J Cryst Growth 225:540–543

Newport A, Carmalt CJ, Parkin IP, Oneill SA (2002) The dual source APCVD of titanium nitride thin films from reaction of hexamethyldisilazane and titanium tetrachloride. J Mater Chem 12:1906–1909

Schneider R, Weigert F, Lesnyak V, Leubner S, Lorenz T, Behnke T, Dubavik A, Joswig JO, Resch-Genger U, Gaponikc N, Eychmüllerc A (2016) pH and concentration dependence of the optical properties of thiol-capped CdTe nanocrystals in water and D2O. Phys Chem Chem Phys 18:19083–19093

Sarkar S, Das R (2018) Shape effect on the elastic properties of Ag nanocrystals. Micro Nano Lett 13:312–315

Thool GS, Singh AK, Singh RS, Gupta A, Susan MABH (2014) Facile synthesis of flat crystal ZnO thin films by solution growth method: a micro-structural investigation. J Saudi Chem Soc 18:712–721

Mahmood NB, Al-Shakarchi EK (2011) Three techniques used to produce BaTiO3 fine powder. J Mod Phys 2:1420–1428

Cullity BD, Stock SR (2001) Elements of X-ray diffraction. Addison-Wesley Publishing Company, Boston

Guinier A (1994) Imperfect crystals and amorphous bodies. Dover, New York

Das S, Guha S, Das PP, Ghadai RK (2020) Analysis of morphological, microstructural, electrochemical and nano mechanical characteristics of TiCN coatings prepared under N2 gas flow rate by chemical vapour deposition (CVD) process at higher temperature. Ceram Int 46:10292–10298

Das S, Guha S, Ghadai R, Kumar D, Swain BP (2017) Structural and mechanical properties of CVD deposited titanium aluminium nitride (TiAlN) thin films. Appl Phys A Mater Sci Process 123:412–416

Guha S, Das S, Bandyopadhyay A, Das S, Swain BP (2018) Investigation of mechanical properties of CVD grown titanium silicon nitride thin films under reduced atmosphere. Appl Phys A Mater Sci Process 124:35–43

Das S, Guha S, Ghadai R, Swain BP (2020) A comparative analysis over different properties of TiN, TiAlN and TiAlSiN thin film coatings grown in nitrogen gas atmosphere. Mater Chem Phy 258:123866

Amirzada MR, Tatzel A, Viereck V (2016) Surface roughness analysis of SiO2 for PECVD, PVD and IBD on different substrates. Appl Nanosci 6:215–222

Delhez R, de Keijser TH, Mittemeijer EJ (1982) Determination of crystallite size and lattice distortions through X-ray diffraction line profile analysis. Fresenius Z Anal Chem 312:1–16

Das R, Nath SS, Bhattacharjee R (2010) Preparation of linoleic acid capped gold nanoparticles and their spectra. Phys E 43:224–227

Dey PC, Das R (2018) Effect of silver doping on the elastic properties of CdS nanoparticles. Indian J Phys 92:1099–1108

Yogamalara R, Srinivasan R, Vinu A, Ariga K, Bose AC (2009) X-ray peak broadening analysis in ZnO nanoparticles. Solid State Commun 149:1919–1923

Schumacher G, Dittrich M (2014) Evolution of crystallite size, lattice parameter and internal strain in Al precipitates during high energy ball milling of partly amorphous Al87Ni8La5 alloy. Mater Sci Eng A 604:27–33

Vashista M, Paul S (2013) Correlation between full width at half maximum (FWHM) of XRD peak with residual stress on ground surfaces. Philos Mag 92:4194–4204

Hall WH (1949) X-ray line broadening in metals. Proc Phys Soc Sect A 62:741–743. https://doi.org/10.1088/0370-1298/62/11/110

Nath D, Singh F, Das R (2020) X-ray diffraction analysis by Williamson-Hall, Halder-Wagner and size-strain plot methods of CdSe nanoparticles- a comparative study. Mater Chem Phys 239:122021

Sarkar S, Das R (2018) Determination of structural elements of synthesized silver nanohexagon from X-ray diffraction analysis. Indian J Pure Appl Phys 56:765–772

Wang A, Shang SL, He M, Du Y et al (2014) Temperature-dependent elastic stiffness constants of fcc-based metal nitrides from first-principles calculations. J Mater Res 49:424–432

Mote VD, Purushotham Y, Dole BN (2012) Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J Theor Appl Phys 6:6–14

Balzar D, Ledbetter H (1993) Voigt-function modeling in fourier analysis of size- and strain-broadened X-ray diffraction peaks. J Appl Crystallogr 26:97–103

Hepp A, Baerlocher C (1988) Learned peak shape functions for powder diffraction data. Aust J Phys 41:229–236

Halder NC, Wagner CNJ (1966) Separation of particle size and lattice strain in integral breadth measurements. Acta Crystallogr 20(2):312–331

Motevalizadeh L, Heidary Z, Abrishami ME (2014) Facile template-free hydrothermal synthesis and microstrain measurement of ZnO nanorods. Bull Mater Sci 37(3):397–405

Chan YC, Chen HW, Chao PS, Duh JG, Lee JW (2013) Microstructure control in TiAlN/SiNx multilayers with appropriate thickness ratios for improvement of hardness and anti-corrosion characteristics. Vacuum 87:195–199

Jung DH, Moon KI, Shin SY, Lee CS (2013) Influence of ternary elements (X = Si, B, Cr) on TiAlN coating deposited by magnetron sputtering process with single alloying targets. Thin Solid Films 546:242–245

Guha S, Das S, Bandyopadhyay A, Das S, Swain BP (2018) Investigation of structural network and mechanical properties of titanium silicon nitride (TiSiN) thin films. J Alloy Compd 731:347–353

Chang L, Zhang LC (2009) Deformation mechanism at pop-out in monocrystalline silicon under nanoindentation. Acta Mater 57:2148–2153

Sneddon IN (1965) The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3:47–57

Li X, Bhusan B (2002) A review of nanoindentation continuous stiffness measurement technique and its applications. Mater Charact 48:11–36

Maxwell AS, Owen-Jones S, Jennett NM (2004) Measurement of Young’s modulus and Poisson’s ratio of thin coatings using impact excitation and depth-sensing indentation. Rev Sci Instrum 75:970–975

Lee JH, Nathanael AJ, Hong SI (2012) Effect of nitrogen flow rate on the structure and properties of TiN thin films deposited onto β-type Ti-15Mo-3Nb-3Al-0.2Si alloy substrates by reactive magnetron sputtering. Adv Mater Res 557–559:1998–2001

Pellicer E, Pane S, Sivaraman KM, Ergeneman O, Suri S, Bar MD, Nelson BJ, Sort J (2011) Effects of the anion in glycine-containing electrolytes on the mechanical properties of electrodeposited co-Ni films. Mater Chem Phys 130:1380–1386

Medeiros BB, Medeiros MM, Fornell J, Sort J, Baro MD, Jorge Junior AM (2015) Nanoindentation response of cu-Ti based metallic glasses: comparison between as-cast, relaxed and de vitrified states. J Non-Cryst Solids 425:103–109

Hynowska A, Pellicer E, Fornell J, Gonzalez S, Steenberge N, Surinach S, Gebert A, Calin M, Eckert J, Baro MD, Sort J (2012) Nanostructured ß-phase Ti-31.0Fe-9.0Sn and sub-mm structured Ti-39.3Nb-13.3Zr-10.7Ta alloys for biomedical applications: microstructure benefits on the mechanical and corrosion performances. Mater Sci Eng C 32:2418–2425

Bao YW, Wang W, Zhou YC (2004) Investigation of the relationship between elastic modulus and hardness based on depth-sensing indentation measurements. Acta Mater 52:5397–5404

Zhang S (2010) Nanostructured thin films and coatings: mechanical properties. CRC Press, USA

Mott PH, Roland CM (2009) Limits to Poisson’s ratio in isotropic materials. Phys Rev B 80:132104

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J Am Ceram Soc 64:533–538

Nihara K, Morena R, Hasselman DPH (1982) Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. J Mater Sci Lett 1:13–16

Casellas D, Feder A, Llanes L, Anglada M (2001) Fracture toughness and mechanical strength of Y-TZP/PSZ ceramics. Scripta Mater 45:213–220

Laugier MT, Palmqvist (1991) Indentation crack analyses for toughness determination in WC-co composites. J Mater Sci Lett 32:77–84

Ouchterlony F (1977) Symmetric cracking of a wedge by concentrated loads. Int J Eng Sci 15:109–116

Pharr GM (1998) Measurement of mechanical properties by ultra-low load indentation. Mat Sci Eng A 253:151–159

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, S., Guha, S., Ghadai, R. et al. Morphological, Mechanical Property Analysis and Comparative Study over Structural Properties of CVD TiN Film Grown under Different Substrate Temperature in Nitrogen Gas Atmosphere. Silicon 14, 183–199 (2022). https://doi.org/10.1007/s12633-020-00807-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00807-5