Abstract

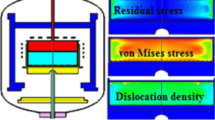

This paper uses the finite element method for numerical simulation and builds a transient global model to simulate polycrystalline silicon ingot growing process in CGsim software. The transient global model is verified through experiments. In addition, the influence of the width and height of the bottom of the side insulation on the temperature field, power consumption and melt-crystal interface (m/c interface) of the solidification process are analyzed. And a new hot zone design method is proposed to protect seed crystal silicon. The results show that the residual height of the seed crystal is increased by 4.5 mm through this design. And increasing the width and height of the side insulation bottom can effectively reduce the power consumption by 5 kW and improve the crystal growth interface, which helps to improve the crystal quality and reduce the cost. This study will provide some references for the optimization of polycrystalline silicon ingot growing process.

Similar content being viewed by others

References

Zhou JC, Ke HY, Deng X (2018) Experimental and CFD investigation on temperature distribution of a serpentine tube type photovoltaic/thermal collector[J]. Sol Energy 174:735–742. https://doi.org/10.1016/j.solener.2018.09.063

Zhou JC, Zhang Z, Ke HY (2018) PV module temperature distribution with a novel segmented solar cell absorbance model[J]. Renew Energy:1071–1080. https://doi.org/10.1016/j.renene.2018.09.014

Gu X, Yu XG, Guo KX et al (2012) Seed-assisted cast quasi-single crystalline silicon for photovoltaic application: Towards high efficiency and low cost silicon solar cells[J]. Solar Energy Materials & Solar Cells 101(2):95–101. https://doi.org/10.1016/j.solmat.2012.02.024

Nguyen THT, Liao SH, Chen JC et al (2016) Effects of the hot zone design during the growth of large size multi-crystalline silicon ingots by the seeded directional solidification process[J]. J Cryst Growth 452:27–34. https://doi.org/10.1016/j.jcrysgro.2015.12.045

Yang YM, Yu A, Hsu B et al (2015) Development of high-performance multicrystalline silicon for photovoltaic industry[J]. Prog Photovolt Res Appl 23(3):340–351. https://doi.org/10.1002/pip.2437

Ding C, Huang M, Zhong G et al (2014) A Design of Crucible Susceptor for the seeds preservation during a seeded directional solidification process[J]. J Cryst Growth 387:73–80. https://doi.org/10.1016/j.jcrysgro.2013.08.039

Q.H. Yu, L.J. Li, W.C Ma, et al. Local design of the hot-zone in an industrial seeded directional solidification furnace for quasi-single crystalline silicon ingots[J]. J Cryst Growth, 2012, 358: 5–11. https://doi.org/10.1016/j.jcrysgro.2012.07.039

Ma WC, Zhong GX, Sun L et al (2012) Influence of an insulation partition on a seeded directional solidification process for quasi-single crystalline silicon ingot for high-efficiency solar cells[J]. Sol Energy Mater Sol Cells 100:231–238. https://doi.org/10.1016/j.solmat.2012.01.024

Wu ZY, Zhong GX, Zhang ZY et al (2015) Optimization of the high-performance multi-crystalline silicon solidification process by insulation partition design using transient global simulations[J]. J Cryst Growth 426:110–116. https://doi.org/10.1016/j.jcrysgro.2015.05.021

Qi XF, Zhao WH, Li LJ et al (2014) Optimization via simulation of a seeded directional solidification process for quasi-single crystalline silicon ingots by insulation partition design[J]. J Cryst Growth 398(18):5–12. https://doi.org/10.1016/j.jcrysgro.2014.04.011

Liu LJ, Yu QH, Qi XF et al (2015) Controlling solidification front shape and thermal stress in growing quasi-single-crystal silicon ingots: process Design for Seeded Directional Solidification[J]. Appl Therm Eng 91:225–233. https://doi.org/10.1016/j.applthermaleng.2015.08.023

T.H.T Nguyen, J.C. Chen, C. Hu, et al. Numerical analysis of thermal stress and dislocation density distributions in large size multi-crystalline silicon ingots during the seeded growth process[J]. J Cryst Growth, 2016, 468:316–320. https://doi.org/10.1016/j.jcrysgro.2016.09.061

Chen L, Dai B (2012) Optimization of power consumption on silicon directional solidification system by using numerical simulations[J]. J Cryst Growth 354:86–92. https://doi.org/10.1016/j.jcrysgro.2012.06.010

S.G. Nagarajan, M. Srinivasan, K. Aravinth, P. Ramasamy Improving heat transfer properties of DS furnace by the geometrical modifications for enhancing the multi crystalline silicon ingot (mc-Si) quality using transient simulation[J]. Silicon, 2018:1–11. https://doi.org/10.1007/s12633-018-9870-8

Nagarajan SG, Sanmugavel S, Kesavan V et al (2019) Influence of additional insulation block on multi-crystalline silicon ingot growth process for PV appilications[J]. J Cryst Growth 516:10–16. https://doi.org/10.1016/j.jcrysgro.2019.03.017

Kesavan V, Srinivasan M, Ramasamy P (2019) Numerical investigation of directional solidification process for improving multi-crystalline silicon ingot quality for photovoltaic applications[J]. Mater Lett 241:180–183. https://doi.org/10.1016/j.matlet.2018.12.129

Chen WL, Wu ZY, Zhong GX et al (2016) Optimization of heat transfer by adjusting power ratios between top and side heaters for casting high-performance multi-crystalline silicon ingots[J]. J Cryst Growth 451:155–160. https://doi.org/10.1016/j.jcrysgro.2016.07.031

Smirnova OV, Mamedov VM, Kalaev VV (2014) Numerical modeling of stress and dislocations in Si ingots grown by seed-directional solidification and comparison to experimental data[J]. Cryst Growth Des 14(11):5532–5536. https://doi.org/10.1021/cg500736j

Wu ZY, Zhong GX, Zhou XC et al (2016) Upgrade of the hot zone for large-size high-performance multi-crystalline silicon ingot casting[J]. J Cryst Growth 441:58–63. https://doi.org/10.1016/j.jcrysgro.2016.02.012

Yang X, Ma WH, Lv GQ et al (2014) A modified vacuum directional solidification system of multicrystalline silicon based on optimizing for heat transfer[J]. J Cryst Growth 400:7–14. https://doi.org/10.1016/j.jcrysgro.2014.04.025

Ma W, Zhong G, Sun L et al (2012) Influence of an insulation partition on a seeded directional solidification process for quasi-single crystalline silicon ingot for high-efficiency solar cells[J]. Sol Energy Mater Sol Cells 100:231–238. https://doi.org/10.1016/j.solmat.2012.01.024

Wei J, Zhang H, Zheng LL et al (2009) Modeling and improvement of silicon ingot directional solidification for industrial production systems[J]. Sol Energy Mater Sol Cells 93(9):1531–1539. https://doi.org/10.1016/j.solmat.2009.04.001

Li J, Chen YF, Hong RJ (2016) Modeling and optimization of the feedstock melting for industrial photovoltaic multi-crystalline silicon ingot[J]. Sol Energy 139:108–115. https://doi.org/10.1016/j.solener.2016.09.024

Ma X, Zheng LL, Zhang H et al (2011) Thermal system design and optimization of an industrial silicon directional solidification system[J]. J Cryst Growth 318(1):288–292. https://doi.org/10.1016/j.jcrysgro.2010.10.102

Acknowledgments

This work was funded by Hunan Province Science and Technology Department ‘Innovative Venture Technology Investment Project’ number 2017GK5002 and by Fundamental Research Funds for the Central Universities of Central South University ‘key project’ CX20190199. We thank B.X. Zhao and X.W. Cai for discussions and experimental and technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, J., Ren, Y., Cao, Y. et al. Effect of Hot Zone Design on Polycrystalline Silicon Ingot Growth Process by Seeded Directional Solidification. Silicon 13, 523–530 (2021). https://doi.org/10.1007/s12633-020-00450-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00450-0