Abstract

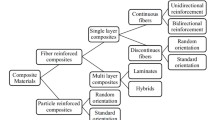

Performance of conventional materials in diverse engineering application is not satisfactory due to the development in products design and engineering materials. In this case, fiber reinforced Polymers (FRPs) have attracted the material engineers with their unique properties and their expansion in various applications. The superior characteristics of the FRPs emphasized their advancement in machining performance. So it becomes more significant to analyze their machinability for further improvement in their machining characteristics and applications. The intention of this paper is to review the machining response of FRPs especially on drilling. Concerning FRPs drilling operation the main aspects were focused on glass, natural and carbon fiber reinforced polymers. Drilling damages such as delamination of plies, thrust force, and surface quality in response to various parameter influences were also discussed in detail.

Similar content being viewed by others

References

Gay D (2014) Composite materials: design and applications, 3rd edn. CRC Press, Boca Raton. ISBN 9781420031683

Nassar MMA, Arunachalam R, Alzebdeh KI (2016) Machinability of natural fiber reinforced composites: a review. Int J Adv Manuf Technol 88:2985–3005

Ismail SO, Dhakal HN, Dimla E et al (2016) Comprehensive study on machinability of sustainable and conventional fibre reinforced polymer composites. Eng Sci Technol, Int J 19:2043–2052

Hejjaji A, Singh D, Kubher S et al (2016) Machining damage in FRPs: laser versus conventional drilling. Compos A: Appl Sci Manuf 82:42–52

Lopresto V, Caggiano A, Teti R et al (2016) High performance cutting of fibre reinforced plastic composite materials. In: Procedia CIRP. 7th HPC—CIRP conference on high performance cutting, Chemnitz

Lazar MB, Xirouchakis P (2011) Experimental analysis of drilling fiber reinforced composites. Int J Mach Tools Manuf 51:937–946

Nasir A, Azmi A, Khalil A (2015) Parametric study on the residual tensile strength of flax natural fibre composites after drilling operation. Procedia Manuf 2:97–101

Sheikh Y, Shinde SR (2016) Machinability of carbon/epoxy composites by electrical discharge machining. Int J Mach Mach Mater 18:3–17

Debnath K, Singh I, Dvivedi A (2014) Evaluation of surface roughness during rotary-mode ultrasonic drilling of glass/epoxy composite laminates. J Prod Eng 17:16–20

Cenna A, Mathew P (2002) Analysis and prediction of laser cutting parameters of fibre reinforced plastics (FRP) composite materials. Int J Mach Tools Manuf 42:105–113

Kalirasu S, Rajini N, Jappes T et al (2015) Mechanical and machining performance of glass and coconut sheath fibre polyester composites using AWJM. J Reinf Plast Compos 34:564–580

Karimi N, Heidary H, Minak G et al (2013) Effect of the drilling process on the compression behavior of glass/epoxy laminates. Compos Struct 98:59–68

Xu J, Mkaddem A, Mansori M (2016) Recent advances in drilling hybrid FRP/Ti composite: a state-of-the-art review. Compos Struct 135:316–338

Arul S, Vijayaraghavan L, Malhotra SK et al (2006) The effect of vibratory drilling on hole quality in polymeric composites. Int J Mach Tools Manuf 46:252–259

Desikan B, Jenarthanan MB (2016) Mathematical modeling of surface roughness during drilling of resin hybrid GFRP composites. Appl Mech Mater 854:18–25

Durão L, Gonçalves D, Tavares JM et al (2010) Drilling process of composite laminates—a tool based analysis. In: 14th European conference on composite materials. Budapest

Mohan NS, Ramachandra A, Kulkarni SM (2005) Influence of process parameters on cutting force and torque during drilling of glass-fiber polyester reinforced composites. Compos Struct 71:407–413

Zitoune R, Collombet F (2007) Numerical prediction of the thrust force responsible of delamination during the drilling of the long-fibre composite structures. Composites: Part A 38:858–866

Ameur MF, Habak M, Kenane M et al (2017) Machinability analysis of dry drilling of carbon/epoxy composites: cases of exit delamination and cylindricity error. Int J Adv Manuf Technol 88:2557–2571

Wang X, Kwon PY, Sturtevant C et al (2013) Tool wear of coated drills in drilling CFRP. J Manuf Process 15:87–95

Rawat S, Attia H (2009) Wear mechanisms and tool life management of WC-Co drills during dry high speed drilling of woven carbon fibre composites. Wear 267:1022–1030

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf 49:1185–1196

Gaugel S, Sripathy P, Haeger A et al (2016) A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers (CFRP). Compos Struct 155:173–183

Palanikumar K (2011) Experimental investigation and optimisation in drilling of GFRP composites. Measurement 44:2138–2148

Karimi NZ, Heidary H, Fotouhi M et al (2017) Experimental analysis of GFRP laminates subjected to compression after drilling. Compos Struct 169:144–152

Velayudham A, Krishnamurthy R (2007) Effect of point geometry and their influence on thrust and delamination in drilling of polymeric composites. J Mater Process Technol 185:204–209

Srinivasan T, Palanikumar K, Rajagopal Latha B (2017) Optimization of delamination factor in drilling GFR-polypropylene composites. Mater Manuf Process 32:226–233

Shetty N, Shetty D, Vijay GS et al (2015) Mechanical characterization and evaluation of delamination of polymer composite laminate. Int J Appl Eng Res 10:35757–35769

Hocheng H, Tsao CC (2003) Comprehensive analysis of delamination in drilling of composite materials with various drill bits. Int J Mater Process Technol 140:335–339

Hocheng H, Tsao CC (2005) The path towards delamination-free drilling of composite materials. J Mater Process Technol 167:251–264

Gaitonde VN, Karnik SR, Rubio JC et al (2008) Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J Mater Process Technol 203:431–438

Hocheng H, Tsao CC (2003) The effect of chisel length and associated pilot hole on delamination when drilling composite materials. Int J Mach Tools Manuf 43:1087–1092

Tsao CC, Hocheng H (2005) Effect of eccentricity of twist drill and candle stick drill on delamination in drilling composite materials. Int J Mach Tools Manuf 45:125–130

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44:1085–1090

Khashaba UA (2004) Delamination in drilling GFR-thermoset composites. Compos Struct 63:313–327

Grilo TJ, Paulo RMF, Silva CR et al (2013) Experimental delamination analyses of CFRPs using different drill geometries. Compos Part B Eng 45:1344–1350

Rubio CJ, Abrao AM, Faria PE et al (2008) Effects of high speed in the drilling of glass fibre reinforced plastic: evaluation of the delamination factor. Int J Mach Tools Manuf 48:715–720

Kavad BV, Pandey A, Tadavi MV et al (2014) Review paper on effects of drilling on glass fiber reinforced plastic. Procedia Technol 14:457–464

Tan CL, Azmi AI, Muhammad N (2015) Surface roughness analysis of carbon/glass hybrid polymer composites in drilling process based on Taguchi and response surface methodology. Adv Mater Res 1119:622–627

Teti R (2002) Machining of composite materials. CIRP Ann Manuf Technol 51:2611–634

Davim J, Mata F (2005) Optimisation of surface roughness on turning fibre-reinforced plastics (FRPs) with diamond cutting tools. Int J Adv Manuf Technol 26:319–323

Rajamurugan TV, Shanmugam K, Palanikumar K (2013) Analysis of delamination in drilling glass fiber reinforced polyester composites. Mater Des 45:80–87

Palanikumar K, Karunamoorthy L, Karthikeyan R (2006) Assessment of factors influencing surface roughness on the machining of glass fiber-reinforced polymer composites. Mater Des 27:862–871

Palanikumar K (2008) Application of Taguchi and response surface methodologies for surface roughness in machining glass fiber reinforced plastics by PCD tooling. Int J Adv Manuf Technol 36:19–27

Hutyrová Z, Zajac J, Michalik P et al (2015) Study of surface roughness of machined polymer composite material. Int J Polym Sci Article ID 303517. https://doi.org/10.1155/2015/303517

Ismail SO, Dhakal HN, Dimla E et al (2016) Effects of drilling parameters and aspect ratios on delamination and surface roughness of lingo cellulosic HFRP composite laminates. J Appl Polym Sci 133:1–8

Tan CL, Azmi AI, Muhammad et al (2016) Delamination and surface roughness analyses in drilling hybrid carbon/glass composite. Mater Manuf Process 31:1366–1376

Rubio CJ, Panzera TH, Abrao AM et al (2010) Effects of high speed in the drilling of glass whisker-reinforced polyamide composites (PA66 GF30): statistical analysis of the roughness parameters. J Compos Mater 45:1395–1402

Angadi SB, Melinamani R, Gaitonde VN et al (2015) Experimental investigations on drilling characteristics of cenosphere reinforced epoxy composites. Appl Mech Mater 766:801–811

Mohan NS, Shettar M, Hiremath P (2015) Influence of drilling conditions of Glass Fiber-Reinforced Plastic [GFRP] composite materials. In: 4th world conference on applied sciences, engineering & technology 24–26 October 2015. Kumamoto University, Japan

Kumar D, Singh KK, Zitoune R (2016) Experimental investigation of delamination and surface roughness in the drilling of GFRP composite material with different drills. Adv Manuf: Polym Compos Sci 2:47–56

Prabhu P, Jawahar, Balasubramanian M et al (2013) Machinability study of hybrid nanoclay-glass fibre reinforced polyester composites. Int J Polym Sci Article ID 416483. https://doi.org/10.1155/2013/416483

Ramesh M, Palanikumar K, Reddy KH (2014) Experimental investigation and analysis of machining characteristics in drilling hybrid glass-sisal-jute fiber reinforced polymer composites. In: 5th international & 26th all india manufacturing technology, design and research conference AIMTDR 2014, December 12th–14th 2014. IIT Guwahati, Assam

El-Sonbaty I, Khashaba UA, Machaly T (2004) Factors affecting the machinability of GFR/epoxy composites. Compos Struct 63:329–338

Krishnaraj V (2008) Effects of drill points on glass fibre reinforced plastic composite while drilling at high spindle speed. In: Proceedings of the world congress on engineering

Adam Khan M, Senthil Kumar A (2011) Machinability of glass fibre reinforced plastic (GFRP) composite using alumina-based ceramic cutting tools. J Manuf Process 13:67–73

Verma R, Abhishek K, Datta S et al (2011) Fuzzy rule based optimization in machining of FRP composites. Turk J Fuzzy Syst 2:1309–1190

Brn M, Rodrigues L, Devineni A (2012) Process parameters optimization in GFRP drilling through integration of Taguchi and response surface methodology. Res J Recent Sci 1:7–15

Davim J, Reis P (2003) Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos Struct 59:481–487

Ariffin M, Ali M, Sapuan S et al (2009) An optimise drilling process for an aircraft composite structure using design of experiments. Sci Res Essays 4:1109–1116

Ali HM, Iqbal A, Liang LA (2013) Comparative study on the use of drilling and milling processes in hole making of GFRP composite. Sadhana - Acad Proc Eng Sci 38:743–760

Uysal A, Altan M, Altan E (2012) Effects of cutting parameters on tool wear in drilling of polymer composite by Taguchi method. Int J Adv Manuf Technol 58:915–921

Ramesh B, Sharan SC, Kavialagan R (2013) Experimental investigation and optimization in drilling GFRP polymeric composites using Taguchi and ANOVA. Int J Mech Prod Eng 2:52–60

El-Sonbaty UA, Khashaba I, Selmy AI et al (2010) Machinability analysis in drilling woven GFR/epoxy composites: part I - Effect of drill wear. Compos A: Appl Sci Manuf 41:391–400

Khashaba UA, El-Sonbaty I, Selmy AI et al (2010) Machinability analysis in drilling woven GFR/epoxy composites: part II - effect of drill wear. Compos A: Appl Sci Manuf 41:1130–1137

Dhawan V, Singh I, Singh S et al (2016) Prediction of forces during drilling of composite laminates using artificial neural network: a new approach. FME Trans 44:36–42

Capello E (2004) Workpiece damping and its effect on delamination damage in drilling thin composite laminates. J Mater Process Technol 148:186–195

Davim P, Mata F (2007) New machinability study of glass fibre reinforced plastics using polycrystalline diamond and cemented carbide (K15) tools. Mater Des 28:1050–1054

Bhatnagar N, Singh I, Nayak D (2004) Materials and manufacturing processes damage investigation in drilling of glass fiber reinforced plastic composite laminates. Mater Manuf Process 196:995–1007

Singh I, Bhatnagar N (2006) Drilling of uni-directional glass fiber reinforced plastic (UD-GFRP) composite laminates. Int J Adv Manuf Technol 27:870–876

Kishore RA, Tiwari R, Dvivedi A et al (2009) Taguchi analysis of the residual tensile strength after drilling in glass fiber reinforced epoxy composites. Mater Des 30:2186–2190

Babu DG, Babu DK, Uma B et al (2013) Effect of machining parameters on milled natural fiber- reinforced plastic composites. J Adv Mech Eng 1:1–12

Babu DG, Babu SK, Gowd UMB (2013) Optimization of machining parameters in drilling hemp fiber reinforced composites to maximize the tensile strength using design experiments. Indian J Eng Mater Sci 20:385–390

Naveen PN, Yasaswi M, Prasad RV (2012) Experimental investigation of drilling parameters on composite materials. J Mech Civil Eng 2:30–37

Velumani S, Krishnan NP, Jayabal S (2013) Mathematical modeling and prediction of the thrust force and torque in drilling of sisal/glass-vinyl ester hybrid composite using the RSM, MLPNN, RBFN and ENN methods. Indian J Eng Mater Sci 20:289–298

Jayabal S, Natarajan U (2011) Drilling analysis of coir–fibre-reinforced polyester composites. Bull Mater Sci 34:1563–1567

Jayabal S, Natarajan U (2010) Optimization of thrust force, torque, and tool wear in drilling of coir fiber-reinforced composites using Nelder-Mead and genetic algorithm methods. Int J Adv Manuf Technol 51:371–381

Durão LP, Gonçalves D, Tavares JR et al (2013) Drilling delamination outcomes on glass and sisal reinforced plastics. Mater Sci Forum 730:301–306

Sridharan V, Muthukrishnan N (2013) Optimization of machinability of polyester/modified jute fabric composite using grey relational analysis (GRA). Procedia Eng 64:1003–1012

Yallew TB, Kumar P, Singh I (2016) A study about hole making in woven jute fabric-reinforced polymer composites. Proc Inst Mech Eng Part L: J Mater: Des Appl 230:888–898

Bajpai KP, Debnath K, Singh I (2015) Hole making in natural fiber-reinforced polylactic acid laminates: an experimental investigation. J Thermoplast Compos Mater 30:30–46

Aravindh VS, Umanath K (2015) Delamination in drilling of natural fibre reinforced polymer composites produced by compression moulding. Appl Mech Mater 766:796–800

Abilash N, Sivapragash M (2016) Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J King Saud Univ—Eng Sci 28:92–102

Vinayagamoorthy R, Rajeswari N, Karthikeyan S (2015) Investigations of damages during drilling of natural sandwich composites. Appl Mech Mater 766:812–817

Uhlmann E, Sammler F, Richarz S et al (2014) Machining of carbon fibre reinforced plastics. Procedia CIRP 24:19–24

Jia Z, Fu R, Niu B et al (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tools Manuf 110:55–65

Hocheng H, Tsao CC (2006) Effects of special drill bits on drilling-induced delamination of composite materials. Int J Mach Tools Manuf 46:1403–1416

Lachaud F, Piquet R, Collombet F et al (2011) Drilling of composite structures. Compos Struct 52:511–516

Eneyew ED, Ramulu M (2014) Experimental study of surface quality and damage when drilling unidirectional CFRP composites. J Mater Res Technol 3:354–362

Li N, Li Y, Zhou J et al (2015) Drilling delamination and thermal damage of carbon nanotubes /carbon fiber reinforced epoxy composites processed by micro wave curing. Int J Mach Tools Manuf 97:11–17

Seif MA, Khashaba UA, Oviedo R (2007) Measuring delamination in carbon/epoxy composites using a shadow moire laser based imaging technique. Compos Struct 79:113–118

Shyha IS, Aspinwall DK, Soo S et al (2009) Drill geometry and operating effects when cutting small diameter holes in CFRP. Int J Mach Tools Manuf 49:1008–1014

Phadnis VA, Makhdum F, Roy A et al (2013) Drilling in carbon/epoxy composites: experimental investigations and finite element implementation. Compos A: Appl Sci Manuf 47:41–51

Feito N, Díaz-Álvarez J, Díaz-Álvarez A et al (2014) Experimental analysis of the influence of drill point angle and wear on the drilling of woven CFRPs. Materials 7:4258–4271

Merino-Pérez JL, Royer R, Merson E et al (2016) Influence of workpiece constituents and cutting speed on the cutting forces developed in the conventional drilling of CFRP composites. Compos Struct 140:621–629

Iliescu D, Gehin D, Gutierrez M et al (2010) Modeling and tool wear in drilling of CFRP. Int J Mach Tools Manuf 50:204–213

Mayuet P, Gallo A, Portal A et al (2013) Damaged area based study of the break-IN and break-OUT defects in the dry drilling of carbon fiber reinforced plastics (CFRP). Procedia Eng 63:743–751

Karpat Y, Deger B, Bahtiyar O (2012) Drilling thick fabric woven CFRP laminates with double point angle drills. J Mater Process Technol 212:2117–2127

Karnik SR, Gaitonde VN, Rubio JC et al (2008) Delamination analysis in high speed drilling of carbon fiber reinforced plastics (CFRP) using artificial neural network model. Mater Des 29:1768–1776

Mata F, Gaitonde VN, Karnik SR et al (2009) Influence of cutting conditions on machinability aspects of PEEK, PEEK CF 30 and PEEK GF 30 composites using PCD tools. J Mater Process Technol 209:1980–1987

Schorník V, Dana M, Zetková I (2015) The influence of the cutting conditions on the machined surface quality when the CFRP is machined. Procedia Eng 100:1270–1276

Feito N, Diaz-Álvarez J, López-Puente J et al (2016) Numerical analysis of the influence of tool wear and special cutting geometry when drilling woven CFRPs. Compos Struct 138:285–294

Krishnaraj V, Prabukarthi A, Ramanathan A et al (2012) Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B Eng 43:1791–1799

Li MJ, Soo SL, Aspinwall DK et al (2014) Influence of lay-up configuration and feed rate on surface integrity when drilling carbon fibre reinforced plastic (CFRP) composites. Procedia CIRP 13:399–404

Heisel U, Pfeifroth T (2012) Influence of point angle on drill hole quality and machining forces when drilling CFRP. Procedia CIRP 1:471–476

Henerichs M, Voß R, Kuster F, Wegener K (2015) Machining of carbon fiber reinforced plastics: influence of tool geometry and fiber orientation on the machining forces. CIRP J Manuf Sci Technol 9:136–145

Koenig W, Wulf C, Willerscheid H (1985) Machining of fiber reinforced plastics manufact. Tech CIRP Ann 34:537–548

Vigneshwaran S, Uthayakumar M, Arumugaprabu V (2017) Abrasive water jet machining of fiber-reinforced composite materials. J Reinf Plast Compos. https://doi.org/10.1177/0731684417740771

Phapale K, Singh R, Patil S et al (2016) Delamination characterization and comparative assessment of delamination control techniques in abrasive water jet drilling of CFRP. Procedia Manuf 5:521–553

Kumaran ST, Ko TJ, Kurniawan R et al (2017) ANFIS modeling of surface roughness in abrasive waterjet machining of carbon fiber reinforced plastics. J Mech Sci Technol 31(8):3949–3954

Wang J, Guo D (2002) A predictive depth of penetration model for abrasive waterjet cutting of polymer matrix composites. J Mater Process Technol 121:390–394

Shanmugam DK, Nguyen T, Wang J (2008) A study of delamination on graphite/epoxy composites in abrasive water jet machining. Compos A: Appl Sci Manuf 39:923–929

Kumaran ST, Ko TJ, Uthayakumar M et al (2017) Prediction of surface roughness in abrasive water jet machining of CFRP composites using regression analysis. J Alloys Compd 724:s1037–s1045

Hocheng H, Hsu CC (1995) Preliminary study of ultrasonic drilling of fiber-reinforced plastics. J Mater Process Technol 48:255–266

Dam H, Quist P (1995) Productivity, surface quality and tolerances in ultrasonic machining of ceramics. J Mater Process Technol 51:358–368

Kurniawan R, Kumaran ST, Prabu V et al (2017) Measurement of burr removal rate and analysis of machining parameters in ultrasonic assisted dry EDM (US-EDM) for deburring drilled holes in CFRP composite. Measurement 110:98–115

Kumaran ST, Ko TJ, Li C et al (2017) Rotary ultrasonic machining of woven CFRP composite in a cryogenic environment. J Alloys Compd 698:984–993

Pan CT, Hocheng H (2001) Evaluation of anistropic thermal conductivity for unidirectional 119 fiber-reinforced plastics in laser machining of uni-directionally fiber-reinforced plastics. Compos Part A 32:1657–1667

Tuersley IP, Hoult TP, Pashby IR (1998) Nd-YAG laser machining of SiC fibre/borosilicate glass composites. Part II—the effect of process variables. Compos Part A 29:955–964

Rodden WSO, Kudesia SS, Hand DP et al (2002) A comprehensive study of the long pulse Nd:YAG laser drilling of multi-layer carbon fibre composites. Opt Commun 210:319–328

Islam MM, Li CP, Won SJ et al (2017) A deburring strategy in drilled hole of CFRP composites using EDM process. J Alloys Compd 703:477–485

Mausam K, Singh PK, Sharma K et al (2016) Investigation of process parameter of EDM using Genetic Algorithm (GA) approach for carbon fiber based two phase epoxy composites. Mater Today: Proc 3:4102–4108

Ramulu M, Spaulding M (2016) Drilling of hybrid titanium composite laminate (HTCL) with electrical discharge machining. Materials 9:746

Acknowledgments

The authors would like to express their sincere thanks to Ministry of environment forest and climatic change (MOEF & CC), Government of India for the financial support (Project No 168/2016/RE (F No 19-20/2012-RE)).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vigneshwaran, S., Uthayakumar, M. & Arumugaprabu, V. Review on Machinability of Fiber Reinforced Polymers: A Drilling Approach. Silicon 10, 2295–2305 (2018). https://doi.org/10.1007/s12633-018-9764-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-9764-9