Abstract

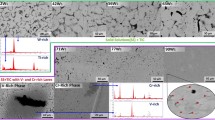

W-based WTaVCr refractory high entropy alloys (RHEA) may be novel and promising candidate materials for plasma facing components in the first wall and diverter in fusion reactors. This alloy has been developed by a powder metallurgy process combining mechanical alloying and spark plasma sintering (SPS). The SPSed samples contained two phases, in which the matrix is RHEA with a body-centered cubic structure, while the oxide phase was most likely Ta2VO6 through a combined analysis of X-ray diffraction (XRD), energy-dispersive spectroscopy (EDS), and selected area electron diffraction (SAED). The higher oxygen affinity of Ta and V may explain the preferential formation of their oxide phases based on thermodynamic calculations. Electron backscatter diffraction (EBSD) revealed an average grain size of 6.2 μm. WTaVCr RHEA showed a peak compressive strength of 2997 MPa at room temperature and much higher micro- and nano-hardness than W and other W-based RHEAs in the literature. Their high Rockwell hardness can be retained to at least 1000°C.

Similar content being viewed by others

References

R.G. Abernethy, Predicting the performance of tungsten in a fusion environment: A literature review, Mater. Sci. Technol., 33(2017), No. 4, p. 388.

K. Huang, L.M. Luo, X. Zan, et al., Microstructure and damage behavior of W–Cr alloy under He irradiation, J. Nucl. Mater., 501(2018), p. 181.

T. Fu, K.K. Cui, Y.Y. Zhang, et al., Oxidation protection of tungsten alloys for nuclear fusion applications: A comprehensive review, J. Alloys Compd., 884(2021), art. No. 161057.

H. Bolt, V. Barabash, W. Krauss, et al, Materials for the plasma-facing components of fusion reactors, J. Nucl. Mater., 329–333(2004), p. 66.

D. Stork, P. Agostini, J.L. Boutard, et al., Developing structural, high-heat flux and plasma facing materials for a near-term DEMO fusion power plant: The EU assessment, J. Nucl. Mater., 455(2014), No. 1–3, p. 277.

J.H. You, Copper matrix composites as heat sink materials for water-cooled divertor target, Nucl. Mater. Energy, 5(2015), p. 7.

R. Neu, C. Hopf, A. Kallenbach, et al., Operational conditions in a W-clad tokamak, J. Nucl. Mater., 367–370(2007), p. 1497.

C.P.C. Wong, C. Baxi, R. Bourque, et al., Helium cooling of fusion reactors, Fusion Eng. Des., 25(1994), No. 1–3, p. 249.

J. Linke, J. Du, T. Loewenhoff, et al., Challenges for plasma-facing components in nuclear fusion, Matter Radiat. Extrem., 4(2019), No. 5, art. No. 056201.

B. Riccardi, P. Gavila, J. Andrade, et al., Progress of the EU activities for the ITER Divertor Inner Vertical Target procurement, Fusion Eng. Des., 146(2019), p. 1524.

J. Schlosser, F. Escourbiac, M. Merola, et al., Technologies for ITER divertor vertical target plasma facing components, Nucl. Fusion, 45(2005), No. 6, p. 512.

K. Krieger, H. Maier, and R. Neu, Conclusions about the use of tungsten in the divertor of ASDEX upgrade, J. Nucl. Mater., 266–269(1999), p. 207.

N.M. Almousa and M. Bourham, Simulation of erosion and re-deposition of plasma facing materials under transient plasma instabilities, IEEE Trans. Plasma Sci., 48(2020), No. 6, p. 1512.

M.I. Patino, D. Nishijima, M. Tokitani, D. Nagata, J.H. Yu, and R.P. Doerner, Material migration in W and Mo during bubble growth and fuzz formation, Nucl. Fusion, 61(2021), No. 7, art. No. 076001.

F. Sefta, K.D. Hammond, N. Juslin, and B.D. Wirth, Tungsten surface evolution by helium bubble nucleation, growth and rupture, Nucl. Fusion, 53(2013), No. 7, art. No. 073015.

P. Gumbsch, J. Riedle, A. Hartmaier, and H.F. Fischmeister, Controlling factors for the brittle-to-ductile transition in tungsten single crystals, Science, 282(1998), No. 5392, p. 1293.

P. Gumbsch, Brittle fracture and the brittle-to-ductile transition of tungsten, J. Nucl. Mater., 323(2003), No. 2–3, p. 304.

E.Y. Ivanov, C. Suryanarayana, and B.D. Bryskin, Synthesis of a nanocrystalline W–25 wt.% Re alloy by mechanical alloying, Mater. Sci. Eng. A, 251(1998), No. 1–2, p. 255.

T. Hwang, A. Hasegawa, K. Tomura, et al., Effect of neutron irradiation on rhenium cluster formation in tungsten and tungsten-rhenium alloys, J. Nucl. Mater., 507(2018), p. 78.

R. Mateus, M. Dias, J. Lopes, et al., Blistering of W-Ta composites at different irradiation energies, J. Nucl. Mater., 438(2013), p. S1032.

K. Arshad, M.Y. Zhao, Y. Yuan, et al., Effects of vanadium concentration on the densification, microstructures and mechanical properties of tungsten vanadium alloys, J. Nucl. Mater., 455(2014), No. 1–3, p. 96.

P.B. Kemp and R.M. German, Grain growth in liquid-phase-sintered W–Mo–Ni–Fe alloys, J. Less Common Met., 175(1991), No. 2, p. 353.

C.L. Chen and Y. Zeng, Synthesis and characteristics of W–Ti alloy dispersed with Y2Ti2O7 oxides, Int. J. Refract. Met. Hard Mater., 56(2016), p. 104.

O. El-Atwani, N. Li, M. Li, et al., Outstanding radiation resistance of tungsten-based high-entropy alloys, Sci. Adv., 5(2019), No. 3, art. No. eaav2002.

O.A. Waseem and H.J. Ryu, Powder metallurgy processing of a WxTaTiVCr high-entropy alloy and its derivative alloys for fusion material applications, Sci. Rep., 7(2017), No. 1, art. No. 1926.

O.A. Waseem, J. Lee, H.M. Lee, and H.J. Ryu, The effect of Ti on the sintering and mechanical properties of refractory high-entropy alloy TixWTaVCr fabricated via spark plasma sintering for fusion plasma-facing materials, Mater. Chem. Phys., 210(2018), p. 87.

D.B. Miracle and O.N. Senkov, A critical review of high entropy alloys and related concepts, Acta Mater., 122(2017), p. 448.

J.M. Torralba, P. Alvaredo, and A. García-Junceda, High-entropy alloys fabricated via powder metallurgy. A critical review, PowderMetall., 62(2019), No. 2, p. 84.

Y. Zhang, T.T. Zuo, Z. Tang, et al., Microstructures and properties of high-entropy alloys, Prog. Mater. Sci., 61(2014), p. 1.

O.N. Senkov, D.B. Miracle, K.J. Chaput, and J.P. Couzinie, Development and exploration of refractory high entropy alloys—A review, J. Mater. Res., 33(2018), No. 19, p. 3092.

W. Xiong, A.X.Y. Guo, S. Zhan, C.T. Liu, and S.C. Cao, Refractory high-entropy alloys: A focused review of preparation methods and properties, J. Mater. Sci. Technol., 142(2023), p. 196.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Refractory high-entropy alloys, Intermetallics, 18(2010), No. 9, p. 1758.

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys, Inter-metallics, 19(2011), No. 5, p. 698.

S. Alvi and F. Akhtar, High temperature tribology of Cu-MoTaWV high entropy alloy, Wear, 426.

B. Kang, J. Lee, H.J. Ryu, and S.H. Hong, Ultra-high strength WNbMoTaV high-entropy alloys with fine grain structure fabricated by powder metallurgical process, Mater. Sci. Eng. A, 712(2018), p. 616.

A.X. Lin-Vines, J.A. Wilson, A. Fraile, et al., Defect behaviour in the MoNbTaVW high entropy alloy (HEA), Results Mater., 15(2022), art. No. 100320.

X.L. Yan, X. Zhang, F. Wang, et al., Fabrication of ODS austenitic steels and CoCrFeNi high-entropy alloys by spark plasma sintering for nuclear energy applications, JOM, 71(2019), No. 8, p. 2856.

C.S. Bonifacio, T.B. Holland, and K. van Benthem, Evidence of surface cleaning during electric field assisted sintering, Scripta Mater., 69(2013), No. 11–12, p. 769.

R. Orrù, R. Licheri, A.M. Locci, A. Cincotti, and G. Cao, Consolidation/synthesis of materials by electric current activated/assisted sintering, Mater. Sci. Eng. R, 63(2009), No. 4–6, p. 127.

X. Zhang, F. Wang, X.L. Yan, X.Z. Li, K. Hattar, and B. Cui, Nanostructured oxide-dispersion-strengthened CoCrFeMnNi high-entropy alloys with high thermal stability, Adv. Eng. Mater., 23(2021), No. 9, art. No. 2100291.

Y.F. Ye, Y.H. Zhang, Q.F. He, et al., Atomic-scale distorted lattice in chemically disordered equimolar complex alloys, Acta Mater., 150(2018), p. 182.

Q.F. He and Y. Yang, On lattice distortion in high entropy alloys, Front. Mater., 5(2018), art. No. 42.

L. Backman and E.J. Opila, Thermodynamic assessment of the group IV, V and VI oxides for the design of oxidation resistant multi-principal component materials, J. Eur. Ceram. Soc., 39(2019), No. 5, p. 1796.

A. Mittal, G.J. Albertsson, G.S. Gupta, S. Seetharaman, and S. Subramanian, Some thermodynamic aspects of the oxides of chromium, Metall. Mater. Trans. B, 45(2014), No. 2, p. 338.

Z. Cao, S. Li, W. Xie, G. Du, and Z. Qiao, Critical evaluation and thermodynamic optimization of the V-O system, Calphad, 51(2015), p. 241.

C.B. Hamilton and H.A. Wilhelm, The preparation of tantalum metal by the carbon reduction of tantalum pentoxide, [in] Proceedings of the Iowa Academy of Science, Iowa, 1961, p. 189.

N. Senthilnathan, A.R. Annamalai, and G. Venkatachalam, Synthesis of tungsten through spark plasma and conventional sintering processes, Mater. TodayProc., 5(2018), No. 2, p. 7954.

O. El-Atwani, D.V. Quach, M. Efe, et al., Multimodal grain size distribution and high hardness in fine grained tungsten fabricated by spark plasma sintering, Mater. Sci. Eng. A, 528(2011), No. 18, p. 5670.

X.H. An, Structural hierarchy defeats alloy cracking, Science, 373(2021), No. 6557, p. 857.

P.J. Shi, R.G. Li, Y. Li, et al., Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys, Science, 373(2021), No. 6557, p. 912.

D.Q. Chen, G.Y. Zhou, Z.P. Liu, and S.T. Tu, Nanoindentation experimental study on mechanical properties of As-cast BNi-2 solder alloy, Procedia Eng., 130(2015), p. 652.

R.S. Ganji, P. Sai Karthik, K. Bhanu Sankara Rao, and K.V. Rajulapati, Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro-and nanoindentation methods, Acta Mater., 125(2017), p. 58.

L.M. Qian, M. Li, Z.R. Zhou, H. Yang, and X.Y. Shi, Comparison of nano-indentation hardness to microhardness, Surf. Coat. Technol., 195(2005), No. 2–3, p. 264.

S. Alvi, D.M. Jarzabek, M.G. Kohan, et al., Synthesis and mechanical characterization of a CuMoTaWV high-entropy film by magnetron sputtering, ACS Appl. Mater. Interfaces, 12(2020), No. 18, p. 21070.

A. Poulia, E. Georgatis, A. Lekatou, and A.E. Karantzalis, Microstructure and wear behavior of a refractory high entropy alloy, Int. J. Refract. Met. HardMater., 57(2016), p. 50.

H. Jiang, H.Z. Zhang, T.D. Huang, Y.P. Lu, T.M. Wang, and T.J. Li, Microstructures and mechanical properties of Co2MoxNi2VWx eutectic high entropy alloys, Mater. Des., 109(2016), p. 539.

Q.Y. Li, H. Zhang, D.C. Li, et al., WxNbMoTa refractory high-entropy alloys fabricated by laser cladding deposition, Materials, 12(2019), No. 3, art. No. 533.

Z. Wang, Y. Yuan, K. Arshad, et al., Effects of tantalum concentration on the microstructures and mechanical properties of tungsten-tantalum alloys, Fusion Eng. Des., 125(2017), p. 496.

T. Gräning, M. Klimenkov, M. Rieth, C. Heintze, and A. Möslang, Long-term stability of the microstructure of austenitic ODS steel rods produced with a carbon-containing process control agent, J. Nucl. Mater., 523(2019), p. 111.

J. Svoboda, P. Boril, J. Holzer, et al., Substantial improvement of high temperature strength of new-generation nano-oxide-strengthened alloys by addition of metallic yttrium, Materials, 15(2022), No. 2, art. No. 504.

S. Ukai, S. Ohtsuka, T. Kaito, et al., High-temperature strength characterization of advanced 9Cr–ODS ferritic steels, Mater. Sci. Eng. A, 510–511(2009), p. 115.

L. Fave, M.A. Pouchon, M. Döbeli, M. Schulte-Borchers, and A. Kimura, Helium ion irradiation induced swelling and hardening in commercial and experimental ODS steels, J. Nucl. Mater., 445(2014), No. 1–3, p. 235.

C.Y. Lu, Z. Lu, X. Wang, et al., Enhanced radiation-tolerant oxide dispersion strengthened steel and its microstructure evolution under helium-implantation and heavy-ion irradiation, Sci. Rep., 7(2017), art. No. 40343.

Acknowledgements

This material is based upon work supported by the National Science Foundation under Grant No. CMMI-1762190. The research was performed in part in the Nebraska Nano-scale Facility: National Nanotechnology Coordinated Infrastructure and the Nebraska Center for Materials and Nanoscience (and/or NERCF), which are supported by the National Science Foundation under Award ECCS: 2025298, and the Nebraska Research Initiative. This work was supported by the U.S. Department of Energy, Office of Nuclear Energy under DOE Idaho Operations Office Contract DE-AC07-051D14517 as part of a Nuclear Science User Facilities experiment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Bai Cui is an editorial board member for this journal and was not involved in the editorial review or the decision to publish this article. The authors declare no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Yoo, Y., Zhang, X., Wang, F. et al. Spark plasma sintering of tungsten-based WTaVCr refractory high entropy alloys for nuclear fusion applications. Int J Miner Metall Mater 31, 146–154 (2024). https://doi.org/10.1007/s12613-023-2711-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2711-9