Abstract

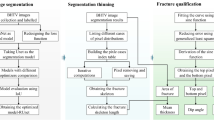

Tensile and shear fractures are significant mechanisms for rock failure. Understanding the fractures that occur in rock can reveal rock failure mechanisms. Scanning electron microscopy (SEM) has been widely used to analyze tensile and shear fractures of rock on a mesoscopic scale. To quantify tensile and shear fractures, this study proposed an innovative method composed of SEM images and deep learning techniques to identify tensile and shear fractures in red sandstone. First, direct tensile and preset angle shear tests were performed for red sandstone to produce representative tensile and shear fracture surfaces, which were then observed by SEM. Second, these obtained SEM images were applied to develop deep learning models (AlexNet, VGG13, and SqueezeNet). Model evaluation showed that VGG13 was the best model, with a testing accuracy of 0.985. Third, the features of tensile and shear fractures of red sandstone learned by VGG13 were analyzed by the integrated gradient algorithm. VGG13 was then implemented to identify the distribution and proportion of tensile and shear fractures on the failure surfaces of rock fragments caused by uniaxial compression and Brazilian splitting tests. Results demonstrated the model feasibility and suggested that the proposed method can reveal rock failure mechanisms.

Similar content being viewed by others

References

B.R. Hacker and J.M. Christie, Brittle/ductile and plastic/cataclastic transitions in experimentally deformed and metamorphosed amphibolite, [in] A.G. Duba, W.B. Durham, J.W. Handin, and H.F. Wang, eds., The Brittle-Ductile Transition in Rocks, vol. 56, 1990, p. 127.

Y.J. Xia, H. Zhou, C.Q. Zhang, S.H. He, Y. Gao, and P. Wang, The evaluation of rock brittleness and its application: A review study, Eur. J. Environ. Civ. Eng., 26(2022), No. 1, p. 239.

D.Y. Li, J.Y. Ma, Q.R. Wan, Q.Q. Zhu, and Z.Y. Han, Effect of thermal treatment on the fracture toughness and subcritical crack growth of granite in double-torsion test, Eng. Fract. Mech., 253(2021), art. No. 107903.

J.M. Ramsey and F.M. Chester, Hybrid fracture and the transition from extension fracture to shear fracture, Nature, 428(2004), No. 6978, p. 63.

H.H. Einstein, Fractures: Tension and shear, Rock Mech. Rock Eng., 54(2021), No. 7, p. 3389.

S. Arshadnejad, K. Goshtasbi, and J. Aghazadeh, A model to determine hole spacing in the rock fracture process by non-explosive expansion material, Int. J. Miner. Metall. Mater., 18(2011), No. 5, p. 509.

R.F. Yuan and Y.H. Li, Fractal analysis on the spatial distribution of acoustic emission in the failure process of rock specimens, Int. J. Miner. Metall. Mater., 16(2009), No. 1, p. 19.

M. Imani, H.R. Nejati, K. Goshtasbi, and A. Nazerigivi, Effect of brittleness on the micromechanical damage and failure pattern of rock specimens, Smart Struct. Syst., 29(2022), No. 4, p. 535.

Z.L. Zhou, L.H. Tan, W.Z. Cao, Z.Y. Zhou, and X. Cai, Fracture evolution and failure behaviour of marble specimens containing rectangular cavities under uniaxial loading, Eng. Fract. Mech., 184(2017), p. 183.

B. Shen, The mechanism of fracture coalescence in compression—Experimental study and numerical simulation, Eng. Fract. Mech., 51(1995), No. 1, p. 73.

Z.T. Bieniawski, Mechanism of brittle fracture of rock: Part I—theory of the fracture process, Int. J. Rock Mech. Min. Sci. Geomech. Abstr., 4(1967), No. 4, p. 395.

H. Wagner, Deep mining: A rock engineering challenge, Rock Mech. Rock Eng., 52(2019), No. 5, p. 1417.

L.J. Dong, X.J. Tong, X.B. Li, J. Zhou, S.F. Wang, and B. Liu, Some developments and new insights of environmental problems and deep mining strategy for cleaner production in mines, J. Clean. Prod., 210(2019), p. 1562.

E. Detournay, Mechanics of hydraulic fractures, Annu. Rev. Fluid Mech., 48(2016), p. 311.

X.L. Su, D.Y. Li, Q.Q. Zhu, and J.Y. Ma, Experimental study of fatigue load effect on the hydraulic fracturing behavior of granite, Fatigue Fract. Eng. Mater. Struct., 46(2023), No. 2, p. 540.

F.Q. Gao, D. Stead, and H.P. Kang, Simulation of roof shear failure in coal mine roadways using an innovative UDEC Trigon approach, Comput. Geotech., 61(2014), p. 33.

T.H. Ma, L. Wang, F.T. Suorineni, and C.N. Tang, Numerical analysis on failure modes and mechanisms of mine Pillars under shear loading, Shock. Vib., 2016(2016), p. 1.

Z.L. Liu, C.D. Ma, and X.N. Wei, Electron scanning characteristics of rock materials under different loading methods: A review, Geomech. Geophys. Geo-energy Geo-resour., 8(2022), No. 2, p. 1.

Q.B. Zhang and J. Zhao, Effect of loading rate on fracture toughness and failure micromechanisms in marble, Eng. Fract. Mech., 102(2013), p. 288.

H.H. Einstein and W.S. Dershowitz, Tensile and shear fracturing in predominantly compressive stress fields—A review, Eng. Geol., 29(1990), No. 2, p. 149.

Q.H. Rao, Z.Q. Sun, G.Y. Wang, J.C. Xu, and J.Y. Zhang, Microscopic characteristics of different fracture modes of brittle rock, J. Cent. South Univ. Technol., 8(2001), No. 3, p. 175.

J.Y. Ding, J.D. Liu, C. Li, and H.Y. Yi, Failure mechanism of layered salt rock in three-point bending test, Appl. Mech. Mater., 256–259(2012), p. 48.

Y.L. Chen, S.R. Wang, J. Ni, R. Azzam, and T.M. Fernándezsteeger, An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics, Eng. Geol., 220(2017), p. 234.

T.B. Yin, B.Q. Wu, C. Wang, and Y. Wu, Determination of dynamic tensile strength of microwave-induced basalt using Brazilian test, Rock Mech. Rock Eng., 55(2022), No. 3, p. 1429.

Z.L. Liu, C.D. Ma, X.A. Wei, and W.B. Xie, Experimental study of rock subjected to triaxial extension, Rock Mech. Rock Eng., 55(2022), No. 2, p. 1069.

D.Y. Li, X.L. Su, F.H. Gao, and Z.D. Liu, Experimental studies on physical and mechanical behaviors of heated rocks with prefabricated hole exposed to different cooling rates, Geomech. Geophys. Geo-energy Geo-resour., 8(2022), No. 4, art. No. 125.

L.Q. Huang, J. Wang, A. Momeni, and S.F. Wang, Spalling fracture mechanism of granite subjected to dynamic tensile loading, Trans. Nonferrous Met. Soc. China, 31(2021), No. 7, p. 2116.

G.Y. Wang, R. Yu, D.F. Ma, et al., Failure characteristics and failure process investigation of fine-grained sandstone under impact load by ultrahigh speed DIC and SEM techniques, Int. J. Geomech., 22(2022), No. 7, art. No. 04022108.

C.X. Zhang, D.Y. Li, J.Y. Ma, et al., Dynamic shear fracture behavior of rocks: Insights from three-dimensional digital image correlation technique, Eng. Fract. Mech., 277(2023), art. No. 109010.

Z.G. He, G.S. Li, S.C. Tian, H.Z. Wang, Z.H. Shen, and J.B. Li, SEM analysis on rock failure mechanism by supercritical CO2 jet impingement, J. Petrol. Sci. Eng., 146(2016), p. 111.

D.Y. Li, Z. Sun, T. Xie, X.B. Li, and P.G. Ranjith, Energy evolution characteristics of hard rock during triaxial failure with different loading and unloading paths, Eng. Geol., 228(2017), p. 270.

Z.L. Zhou, X. Cai, D. Ma, L. Chen, S.F. Wang, and L.H. Tan, Dynamic tensile properties of sandstone subjected to wetting and drying cycles, Constr. Build. Mater., 182(2018), p. 215.

A. Keneti and B.A. Sainsbury, Characterization of strain-burst rock fragments under a scanning electron microscope—An illustrative study, Eng. Geol., 246(2018), p. 12.

R. Tao, M. Sharifzadeh, Y. Zhang, and X.T. Feng, Analysis of Mafic rocks Microstructure damage and failure Process under Compression Test Using Quantitative Scanning Electron Microscopy and Digital Images Processing, Eng. Fract. Mech., 231(2020), art. No. 107019.

Q. Jiang, B. Yang, F. Yan, D.P. Xu, G.L. Feng, and S.J. Li, Morphological features and fractography analysis for in situ spalling in the China Jinping underground laboratory with a 2400 m burial depth, Tunn. Undergr. Space Technol., 118(2021), art. No. 104194.

L.T. Dou, K. Yang, and X.L. Chi, Fracture behavior and acoustic emission characteristics of sandstone samples with inclined precracks, Int. J. Coal Sci. Technol., 8(2021), No. 1, p. 77.

S. Liu, J.Y. Xu, S.H. Liu, and P. Wang, Fractal study on the dynamic fracture of red sandstone after F–T cycles, Environ. Earth Sci., 81(2022), No. 5, p. 1.

K.Q. Liu and M. Ostadhassan, Multi-scale fractal analysis of pores in shale rocks, J. Appl. Geophys., 140(2017), p. 1.

Y.M. Lai, K. Zhao, Z.W. He, et al., Fractal characteristics of rocks and mesoscopic fractures at different loading rates, Geomech. Energy Environ., 33(2023), art. No. 100431.

B.X. Li, S. Yu, L. Yang, et al., Multiscale fracture characteristics and failure mechanism quantification method of cracked rock under true triaxial compression, Eng. Fract. Mech., 262(2022), art. No. 108257.

Y.F. Jiang, Z.M. Zhu, L.Y. Yu, L. Zhou, R.F. Zhang, and L.J. Ma, Investigation of the fracture characteristics of granite and green sandstone under different thermal treatments, Theor. Appl. Fract. Mech., 118(2022), art. No. 103217.

J.C. Chen, J.T. Li, J. Wang, Z.M. Shi, H. Lin, and X. Zhang, Investigation on the characteristics of fracture process zone under cyclic loading: Insights from macro-mesoscopic analysis, Theor. Appl. Fract. Mech., 122(2022), art. No. 103616.

Y. Liu, T.S. Ma, H. Wu, and P. Chen, Investigation on mechanical behaviors of shale cap rock for geological energy storage by linking macroscopic to mesoscopic failures, J. Energy Storage, 29(2020), art. No. 101326.

S.C. Wu, L. Chen, and Z.Q. Cheng, Macro and meso research on the zonal disintegration phenomenon and the mechanism of deep brittle rock mass, Eng. Fract. Mech., 211(2019), p. 254.

A. Krizhevsky, I. Sutskever, and G.E. Hinton, ImageNet classification with deep convolutional neural networks, Commun. ACM, 60(2017), No. 6, p. 84.

K. Simonyan and A. Zisserman, Very deep convolutional networks for large-scale image recognition, arXiv, (2014), art. No. 1409.1556.

F.F. Li, A.R. He, Y. Song, et al., Deep learning for predictive mechanical properties of hot-rolled strip in complex manufacturing systems, Int. J. Miner. Metall. Mater., 30(2023), No. 6, p. 1093.

F.N. Iandola, S. Han, M.W. Moskewicz, K. Ashraf, W.J. Dally, and K. Keutzer, SqueezeNet: AlexNet-level accuracy with 50x fewer parameters and <0.5MB model size, arXiv, (2016), art. No. 1602.07360.

A. Paszke, S. Gross, F. Massa, et al., PyTorch: An imperative style, high-performance deep learning library, arXiv, (2019), art. No. 1912.01703.

Z.D. Liu and D.Y. Li, Intelligent hybrid model to classify failure modes of overstressed rock masses in deep engineering, J. Cent. South Univ., 30(2023), No. 1, p. 156.

M. Sundararajan, A. Taly, and Q.Q. Yan, Axiomatic attribution for deep networks, [in] Proceedings of the 34th International Conference on Machine Learning, Sydney, 2017, p. 3319.

Z.D. Liu, D. Jahed Armaghani, P. Fakharian, et al., Rock strength estimation using several tree-based ML techniques, Comput. Model. Eng. Sci., 133(2022), No. 3, p. 799.

A. Basu, D.A. Mishra, and K. Roychowdhury, Rock failure modes under uniaxial compression, Brazilian, and point load tests, Bull. Eng. Geol. Environ., 72(2013), No. 3, p. 457.

E. Hoek and C.D. Martin, Fracture initiation and propagation in intact rock—A review, J. Rock Mech. Geotech. Eng., 6(2014), No. 4, p. 287.

W.R. Wawersik and C. Fairhurst, A study of brittle rock fracture in laboratory compression experiments, Int. J. Rock Mech. Min. Sci. Geomech. Abstr., 7(1970), No. 5, p. 561.

C.A. Tang, H. Liu, P.K.K. Lee, Y. Tsui, and L.G. Tham, Numerical studies of the influence of microstructure on rock failure in uniaxial compression—Part I: Effect of heterogeneity, Int. J. Rock Mech. Min. Sci., 37(2000), No. 4, p. 555.

D.Y. Li, B. Li, Z.Y. Han, Q.Q. Zhu, and M. Liu, Evaluation of Bi-modular behavior of rocks subjected to uniaxial compression and Brazilian tensile testing, Rock Mech. Rock Eng., 54(2021), No. 8, p. 3961.

D.Y. Li and L.N.Y. Wong, The Brazilian disc test for rock mechanics applications: Review and new insights, Rock Mech. Rock Eng., 46(2013), No. 2, p. 269.

D.W. Hobbs, The tensile strength of rocks, Int. J. Rock Mech. Min. Sci. Geomech. Abstr., 1(1964), No. 3, p. 385.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 52074349) and the Fundamental Research Funds for the Central Universities of Central South University (No. 2023zzts0726).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Supplementary Information

Rights and permissions

About this article

Cite this article

Liu, Z., Li, D., Zhu, Q. et al. Intelligent method to experimentally identify the fracture mechanism of red sandstone. Int J Miner Metall Mater 30, 2134–2146 (2023). https://doi.org/10.1007/s12613-023-2668-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2668-8