Abstract

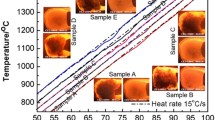

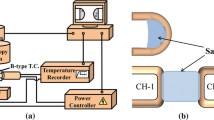

Mold flux serves the crucial metallurgical function of absorbing inclusions, directly impacting the smoothness of the casting process as well as the cast slab quality. In this study, the dissolution behavior and mechanism of TiO2 and TiN inclusions in molten CaO–SiO2–B2O3-based fluorine-free mold flux were explored by in situ single hot thermocouple technology combined with X-ray photoelectron spectroscopy. The results showed that TiO2 inclusions are effectively dissolved by the molten slag within 76 s, during which the original octahedral [TiO6]8− structures are destroyed and convert to the networker tetrahedral [TiO4]4− structures. However, the dissolution rate is much lower for TiN inclusions than for TiO2 inclusions. This can be attributed to the fact that the TiN particles need to be oxidized and then dissolved in the molten slag to form tetrahedral [TiO4]4− and octahedral [TiO6]8− structures during the TiN inclusion dissolution process, which is accompanied by the generation of a large amount of N2 gas. Moreover, CaTiO3 crystals tend to nucleate and grow on bubble surfaces with sufficient octahedral [TiO6]8− structures and Ca2+ ions, eventually resulting in the molten slag being in a solid–liquid mixed state.

Similar content being viewed by others

References

H.W. Yen, C.Y. Chen, T.Y. Wang, C.Y. Huang, and J.R. Yang, Orientation relationship transition of nanometre sized interphase precipitated TiC carbides in Ti bearing steel, Mater. Sci. Technol., 26(2010), No. 4, p. 421.

L.D. Xing, J.L. Guo, X. Li, et al., Control of TiN precipitation behavior in titanium-containing micro-alloyed steel, Mater. Today Commun., 25(2020), art. No. 101292.

Y.F. Shen, C.M. Wang, and X. Sun, A micro-alloyed ferritic steel strengthened by nanoscale precipitates, Mater. Sci. Eng. A, 528(2011), No. 28, p. 8150.

Z. Chen, M. Li, X.F. Wang, S.P. He, and Q. Wang, Mechanism of floater formation in the mold during continuous casting of Ti-stabilized austenitic stainless steels, Metals, 9(2019), No. 6, art. No. 635.

T.F. Zhao, X. Zheng, D.J. Huang, Z.H. Zhu, and Z.H. Yin, Thermodynamic research on the precipitation of Ti2O3, TiN and TiC in continuous casting of titanium microalloyed steel, J. Phys.: Conf. Ser., 2076(2021), No. 1, art. No. 012077.

J.Y. Li, G.G. Cheng, Q. Ruan, J.X. Pan, and X.R. Chen, Characteristics of nozzle clogging and evolution of oxide inclusion for Al-killed Ti-stabilized 18Cr stainless steel, Metall. Mater. Teans. B, 50(2019), No. 6, p. 2769.

L.M. Cheng, L.F. Zhang, Y. Ren, and W. Yang, Clogging behavior of a submerged entry nozzle for the casting of Ca-treated Al-killed Ti-bearing steel, Metall. Mater. Trans. B, 52(2021), No. 3, p. 1186.

H. Cui, Y.P. Bao, M. Wang, and W.S. Wu, Clogging behavior of submerged entry nozzles for Ti-bearing IF steel, Int. J. Miner. Metall. Mater., 17(2010), No. 2, p. 154.

S. Basu, S.K. Choudhary, and N.U. Girase, Nozzle clogging behaviour of Ti-bearing Al-killed ultra low carbon steel, ISIJ Int., 44(2004), No. 10, p. 1653.

L.J. Zhou, Z.H. Pan, W.L. Wang, et al., Interfacial interactions between inclusions comprising TiO2 or TiN and the mold flux during the casting of titanium-stabilized stainless steel, Metall. Mater. Trans. B, 51(2020), No. 1, p. 85.

Z.H. Pan, L.J. Zhou, and W.L. Wang, Study on the interaction process between mold flux and TiN/TiO2 by sessile drop method, [in] TMS 2020 149th Annual Meeting & Exhibition Supplemental Peoceedings, The Minerals, Metals & Materials Series, Springer, Cham., 2020, p. 67.

W.L. Wang, D.X. Cai, L. Zhang, and I. Sohn, Effect of TiO2 and TiN on the viscosity, fluidity, and crystallization of fluorine-free mold fluxes for casting Ti-bearing steels, Steel Res. Int., 92(2021), No. 2, art. No. 2000314.

K.C. Mills, A.B. Fox, Z. Li, and R.P. Thackray, Performance and properties of mould fluxes, Ironmaking Steelmaking, 32(2005), No. 1, p. 26.

W.L. Wang, D.X. Cai, and L. Zhang, A review of fluorine-free mold flux development, ISIJ Int., 58(2018), No. 11, p. 1957.

B. Ozturk, Solubility of TiN in continuous casting powders, Metall. Teans. B, 23(1992), No. 4, p. 523.

E.B. Pretorius and R.C. Nunnington, Stainless steel slag fundamentals: From furnace to tundish, Ironmaking Steelmaking, 29(2002), No. 2, p. 133.

Z.S. Ren, X.J. Hu, X.M. Hou, X.X. Xue, and K.C. Chou, Dissolution and diffusion of TiO2 in the CaO–Al2O3–SiO2 slag, Int. J. Miner. Metall. Mater., 21(2014), No. 4, p. 345.

H. Park, J.Y. Park, G.H. Kim, and I. Sohn, Effect of TiO2 on the viscosity and slag structure in blast furnace type slags, Steel Res. Int., 83(2012), No. 2, p. 150.

L.F. Sun, H.P. Wang, M.F. Jiang, Q.Z. Lin, C.L. Liu, and Y. Zou, Effects of TiO2 on the viscocity and solidification temperature of mold fluxes for the stainless steel, Adv. Mater. Res., 189–193(2011), p. 107.

R.C. Nunnington and N. Sutcliffe, The steelmaking and casting of Ti stabilized stainless steels, [in] 59th Electric Furnace Conference and 19th Process Technology Conference, Arizona, 2001, p. 361.

M. Hasegawa, S. Maruhashi, Y. Muranaka, and F. Hoshi, Mechanism of formation of surface defects in continuously cast stainless steel slabs containing titanium, Tetsu-to-Hagane, 73(1987), No. 3, p. 505.

B.Y. Li, X. Geng, Z.H. Jiang, Y. Hou, and W. Gong, Effects of BaO and B2O3 on the absorption of Ti inclusions for high titanium steel, Metals, 11(2021), No. 1, art. No. 165.

Z.S. Bi, K.J. Li, C.H. Jiang, et al., Effects of B2O3 on the structure and properties of blast furnace slag by molecular dynamics simulation, J. Non-Cryst. Solids, 551(2021), art. No. 120412.

F.F. Lai, W. Yao, and J.L. Li, Effect of B2O3 on structure of CaO–Al2O3–SiO2–TiO2–B2O3 glassy systems, ISIJ Int., 60(2020), No. 8, p. 1596.

L.T. Bian and Y.H. Gao, Influence of B2O3 and basicity on viscosity and structure of medium titanium bearing blast furnace slag, J. Chem., 2016(2016), art. No. 6754593

Y.Q. Sun, J.L. Liao, K. Zheng, X.D. Wang, and Z.T. Zhang, Effect of B2O3 on the structure and viscous behavior of Ti-bearing blast furnace slags, JOM, 66(2014), No. 10, p. 2168.

L. Zhang and W.L. Wang, Growth mechanism and structure evolution during nucleation of calcium borosilicate crystal in CaO–SiO2–B2O3 based fluorine-free mold flux, ISIJ Int., 59(2019), No. 6, p. 1041.

L. Zhang, W.L. Wang, and I. Sohn, Crystallization behavior and structure analysis for molten CaO–SiO2–B2O3 based fluorine-free mold fluxes, J. Non-Cryst. Solids, 511(2019), p. 41.

L. Zhang, W.L. Wang, B.Y. Zhai, and I. Sohn, The evolution of the mold flux melt structure during the process of fluorine replacement by B2O3, J. Am. Ceram. Soc., 103(2020), No. 1, p. 112.

J.J. Zhang, B.Y. Zhai, L. Zhang, and W.L. Wang, A comparison study on interfacial properties of fluorine-bearing and fluorine-free mold flux for casting advanced high-strength steels, J. Iron Steel Res. Int., 29(2022), No. 10, p. 1613.

T.M. Yeo, J.W. Cho, M. Alloni, S. Casagrande, and R. Carli, Structure and its effect on viscosity of fluorine-free mold flux: Substituting CaF2 with B2O3 and Na2O, J. Non-Cryst. Solids, 529(2020), art. No. 119756.

The Materials Project. Materials Data Materials Project for TiO2 (mp-2657) from Database Version v2021 [2022-10-28]. https://doi.org/10.17188/1184648

The Materials Project. Materials Data Materials Project for TiN (mp-492) from Database Version v2021 [2022-10-28]. https://doi.org/10.17188/1208488

X. Wu, S.X. Zhao, L. Wei, E.L. Zhao, J.W. Li, and C.W. Nan, Improved structural reversibility and cycling stability of Li2MnSiO4 cathode material by the pillar effect of [TiOx] polyanions, ChemistrySelect, 3(2018), No. 15, p. 4047.

S.Q. Jin, Z.D. Wang, G.J. Tao, et al., UV resonance Raman spectroscopic insight into titanium species and structure-performance relationship in boron-free Ti-MWW zeolite, J. Catal., 353(2017), p. 305.

Z. Wang, Q.F. Shu, and K. Chou, Structure of CaO-B2O3-SiO2-TiO2 glasses: A Raman spectral study, ISIJ Int., 51(2011), No. 7, p. 1021.

Z. Wang, Q.F. Shu, and K. Chou, Study on structure characteristics of B2O3 and TiO2-bearing F-free mold flux by Raman spectroscopy, High Temp. Mater. Processes, 32(2013), No. 3, p. 265.

X.H. Zhang, Z. Du, H.T. Wu, and Y.L. Yue, Effect of TiO2 on structure and dielectric properties of RO-Al2O3-B2O3-SiO2 (R = Ca, Mg) glasses, Surf. Rev. Lett., 20(2013), No. 03n04, art. No. 1350030.

E. Kleebusch, C. Patzig, T. Hoeche, and C. Russel, The evidence of phase separation droplets in the crystallization process of a Li2O–Al2O3–SiO2 glass with TiO2 as nucleating agent - An X-ray diffraction and (S)TEM-study supported by EDX-analysis, Ceram. Int., 44(2018), No. 3, p. 2919.

G.S. Back, M.J. Yoon, and W.G. Jung, Effect of the Cr2O3 and TiO2 as nucleating agents in SiO2–Al2O3–CaO–MgO glass-ceramic system, Met. Mater. Int., 23(2017), No. 4, p. 798.

Q. Wang, Y.J. Lu, S.P. He, K.C. Mills, and Z.S. Li, Formation of TiN and Ti(C,N) in TiO2 containing, fluoride free, mould fluxes at high temperature, Ironmaking Steelmaking, 38(2011), No. 4, p. 297.

Y.H. Hua and B.J. Zhao, Phase equilibria in the system Al2O3–MnO–SiO2: Thermodynamic and application, [in] 11th International Symposium on High-Temperature Metallurgical Processing, California, 2020, p. 183.

M. Wittmer, J. Noser, and H. Melchior, Oxidation kinetics of TiN thin films, J. Appl. Phys., 52(1981), No. 11, p. 6659.

K. Kusabiraki, Infrared spectra of vitreous silica and sodium silicates containing titanium, J. Non-Cryst. Solids, 79(1986), No. 1–2, p. 208.

D. Yang, H.H. Zhou, J. Wang, et al., Influence of TiO2 on viscosity, phase composition and structure of chromium-containing high-titanium blast furnace slag, J. Mater. Res. Technol., 12(2021), p. 1615.

K. Yan and D.F. Che, A coupled model for simulation of the gas–liquid two-phase flow with complex flow patterns, Int. J. Multiphase Flow, 36(2010), No. 4, p. 333.

S.P. Gu, G.H. Wen, Z.Q. Ding, J.L. Guo, P. Tang, and Q. Liu, Effect of bubbles on crystallization behavior of CaO–SiO2 based slags, Metals, 9(2019), No. 2, art. No. 193.

Acknowledgements

This work was financially supported by the Fellowship of China National Postdoctoral Program for Innovative Talents (No. BX20220357) and the National Science Foundation of China (No. 52130408).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Il Sohn is an editorial board member for this journal and was not involved in the editorial review or the decision to publish this article. The authors state no conflict of interest in publishing this work.

Rights and permissions

About this article

Cite this article

Cai, D., Zhang, L., Wang, W. et al. Dissolution of TiO2 and TiN inclusions in CaO–SiO2–B2O3-based fluorine-free mold flux. Int J Miner Metall Mater 30, 1740–1747 (2023). https://doi.org/10.1007/s12613-023-2622-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2622-9