Abstract

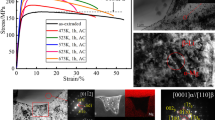

Li addition is verified to be an effective method to increase the room temperature ductility and formability of Mg alloys. In the present study, the microstructure, texture, and tensile properties of the extruded Mg-1Zn-xLi (wt%, x = 0, 1, 3, 5) alloy sheets were studied by X-ray diffraction (XRD), scanning electron microscope (SEM), and electron backscatter diffraction (EBSD). It was found that Li addition resulted in the grain coarsening and the development of new transverse direction (TD)-tilting and 〈\(10\bar{1}0\)〉 parallel to extrusion direction textures, which was related to the improved dynamic recrystallization and the increased prismatic slip during extrusion. The Mg-1Zn−5Li sheet showed the weakest texture, which contained both basal and TD-tilting oriented grains. No additional phase was formed with Li addition. The yield strength of Mg-1Zn-xLi sheets gradually decreased with increasing Li content, which was mainly related to the grain coarsening and texture weakening. In addition, the ductility of the Mg-1Zn-xLi sheet was remarkably enhanced by Li addition. The elongation of the Mg-1Zn-5Li sheet was 30.3% along the TD, which was three times than that of Mg-1Zn sheet. Microstructural analysis implied that this significant ductility enhancement was associated with the improvement activation of prismatic and basal slips during the tensile tests. This study may provide insights into the development of high-ductility, low-density Mg-Zn-Li based alloys.

Similar content being viewed by others

References

Y.Z. Ma, C.L. Yang, Y.J. Liu, F.S. Yuan, S.S. Liang, H.X. Li, and J.S. Zhang, Microstructure, mechanical, and corrosion properties of extruded low-alloyed Mg-xZn−0.2Ca alloys, Int. J. Miner. Metall. Mater., 26(2019), No. 10, p. 1274.

S. Kandemir, S. Gavras, and H. Dieringa, High temperature tensile, compression and creep behavior of recycled short carbon fibre reinforced AZ91 magnesium alloy fabricated by a high shearing dispersion technique, J. Magnes. Alloys, 9(2021), No. 5, p. 1753.

Z. Zhang, J.H. Zhang, J. Wang, Z.H. Li, J.S. Xie, S.J. Liu, K. Guan, and R.Z. Wu, Toward the development of Mg alloys with simultaneously improved strength and ductility by refining grain size via the deformation process, Int. J. Miner. Metall. Mater., 28(2021), No. 1, p. 30.

H.F. Zhang, L. Zhou, W.L. Li, G.H. Li, Y.T. Tang, N. Guo, and J.C. Feng, Effect of tool plunge depth on the microstructure and fracture behavior of refill friction stir spot welded AZ91 magnesium alloy joints, Int. J. Miner. Metall. Mater., 28(2021), No. 4, p. 699.

C. Zhang, L. Wu, Z.L. Zhao, G.S. Huang, B. Jiang, A. Atrens, and F.S. Pan, Effect of the Al-Si eutectic on the microstructure and corrosion behavior of the single-phase Mg alloy Mg-4Li, J. Magnes. Alloys, 9(2021), No. 4, p. 1339.

C.Q. Li, Y.B. He, and H.P. Huang, Effect of lithium content on the mechanical and corrosion behaviors of HCP binary Mg-Li alloys, J. Magnes. Alloys, 9(2021), No. 2, p. 569.

H.T. Son, Y.H. Kim, D.W. Kim, J.H. Kim, and H.S. Yu, Effects of Li addition on the microstructure and mechanical properties of Mg-3Zn−1Sn−0.4Mn based alloys, J. Alloys Compd., 564(2013), p. 130.

B.J. Wang, D.K. Xu, X. Cai, Y.X. Qiao, and L.Y. Sheng, Effect of rolling ratios on the microstructural evolution and corrosion performance of an as-rolled Mg-8 wt%Li alloy, J. Magnes. Alloys, 9(2021), No. 2, p. 560.

Y. Zeng, B. Jiang, Q.R. Yang, G.F. Quan, J.J. He, Z.T. Jiang, and F.S. Pan, Effect of Li content on microstructure, texture and mechanical behaviors of the as-extruded Mg-Li sheets, Mater. Sci. Eng. A, 700(2017), p. 59.

W.C. Liu, S. Feng, Z.Q. Li, J. Zhao, G.H. Wu, X.F. Wang, L. Xiao, and W.J. Ding, Effect of rolling strain on microstructure and tensile properties of dual-phase Mg-8Li−3Al−2Zn−0.5Y alloy, J. Mater. Sci. Technol., 34(2018), No. 12, p. 2256.

J.S. Leu, C.T. Chiang, S. Lee, Y.H. Chen, and C.L. Chu, Strengthening and room temperature age-softening of superlight Mg-Li alloys, J. Mater. Eng. Perform., 19(2010), No. 9, p. 1235.

J. Guo, L.L. Chang, Y.R. Zhao, and Y.P. Jin, Effect of Sn and Y addition on the microstructural evolution and mechanical properties of hot-extruded Mg-9Li−3Al alloy, Mater. Charact., 148(2019), p. 35.

G.Y. Sha, X.G. Sun, T. Liu, Y.H. Zhu, and T. Yu, Effects of Sc addition and annealing treatment on the microstructure and mechanical properties of the as-rolled Mg-3Li alloy, J. Mater. Sci. Technol., 27(2011), No. 8, p. 753.

H.Y. Wang, J. Rong, G.J. Liu, M. Zha, C. Wang, D. Luo, and Q.C. Jiang, Effects of Zn on the microstructure and tensile properties of as-extruded Mg-8Al−2Sn alloy, Mater. Sci. Eng. A, 698(2017), p. 249.

H. Ji, G.H. Wu, W.C. Liu, X.L. Liang, G.L. Liao, and D.H. Ding, Microstructure characterization and mechanical properties of the as-cast and as-extruded Mg-xLi−5Zn−0.5Er (x = 8, 10 and 12wt%) alloys, Mater. Charact., 159(2020), art. No. 110008.

Y. Tang, Q.C. Le, R.D.K. Misra, G.Q. Su, and J.Z. Cui, Influence of extruding temperature and heat treatment process on microstructure and mechanical properties of three structures containing Mg-Li alloy bars, Mater. Sci. Eng. A, 712(2018), p. 266.

Y.H. Sun, R.C. Wang, J. Ren, C.Q. Peng, and Z.Y. Cai, Microstructure, texture, and mechanical properties of as-extruded Mg-xLi−3Al−2Zn−0.2Zr alloys (x = 5, 7, 8, 9, 11 wt%), Mater. Sci. Eng. A, 755(2019), p. 201.

Y.H. Sun, R.C. Wang, C.Q. Peng, and Z.Y. Cai, Microstructure and corrosion behavior of as-extruded Mg-xLi−3Al−2Zn−0.2Zr alloys (x = 5, 8, 11wt.%), Corros. Sci., 167(2020), art. No. 108487.

A. Ahmadieh, J. Mitchell, and J.E. Dorn, Lithium alloying and dislocation mechanisms for prismatic slip in magnesium, Trans. Metall. Soc. AIME, 233(1965), p. 1130.

T. Al-Samman, Comparative study of the deformation behavior of hexagonal magnesium-lithium alloys and a conventional magnesium AZ31 alloy, Acta Mater., 57(2009), No. 7, p. 2229.

Y. Zeng, B. Jiang, R.H. Li, J.J. He, X.S. Xia, and F.S. Pan, Effect of Li content on microstructure, texture and mechanical properties of cold rolled Mg-3Al−1Zn alloy, Mater. Sci. Eng. A, 631(2015), p. 189.

Q.S. Yang, B. Jiang, B. Song, Z.J. Yu, D.W. He, Y.F. Chai, J.Y. Zhang, and F.S. Pan, The effects of orientation control via tension-compression on microstructural evolution and mechanical behavior of AZ31 Mg alloy sheet, J. Magnes. Alloys, 10(2022), No. 2, p. 411.

Y.F. Chai, Y. Song, B. Jiang, J. Fu, Z.T. Jiang, Q.S. Yang, H.R. Sheng, G.S. Huang, D.F. Zhang, and F.S. Pan, Comparison of microstructures and mechanical properties of composite extruded AZ31 sheets, J. Magnes. Alloys, 7(2019), No. 4, p. 545.

H.X. Li, S.K. Qin, Y.Z. Ma, J. Wang, Y.J. Liu, and J.S. Zhang, Effects of Zn content on the microstructure and the mechanical and corrosion properties of as-cast low-alloyed Mg-Zn-Ca alloys, Int. J. Miner. Metall. Mater., 25(2018), No. 7, p. 800.

M.G. Jiang, C. Xu, H. Yan, G.H. Fan, T. Nakata, C.S. Lao, R.S. Chen, S. Kamado, E.H. Han, and B.H. Lu, Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion, Acta Mater., 157(2018), p. 53.

S. Ando and H. Tonda, Non-basal slips in magnesium and magnesium-lithium alloy single crystals, Mater. Sci. Forum, 350–351(2000), p. 43.

L.W.F. Mackenzie and M. Pekguleryuz, The influences of alloying additions and processing parameters on the rolling microstructures and textures of magnesium alloys, Mater. Sci. Eng. A, 480(2008), No. 1–2, p. 189.

J. Zhao, B. Jiang, Y. Yuan, A.T. Tang, H.R. Sheng, T.H. Yang, G.S. Huang, D.F. Zhang, and F.S. Pan, Influence of Zn addition on the microstructure, tensile properties and work-hardening behavior of Mg-1Gd alloy, Mater. Sci. Eng. A, 772(2020), art. No. 138779.

N. Hansen, Hall-Petch relation and boundary strengthening, Scripta. Mater., 51(2004), No. 8, p. 801.

J. Xu, T.H. Yang, B. Jiang, J.F. Song, J.J. He, Q.H. Wang, Y.F. Chai, G.S. Huang, and F.S. Pan, Improved mechanical properties of Mg-3Al-1Zn alloy sheets by optimizing the extrusion die angles: Microstructural and texture evolution, J. Alloys Compd., 762(2018), p. 719.

Q.H. Wang, Y.Q. Shen, B. Jiang, A.T. Tang, J.F. Song, Z.T. Jiang, T.H. Yang, G.S. Huang, and F.S. Pan, A micro-alloyed Mg-Sn-Y alloy with high ductility at room temperature, Mater. Sci. Eng. A, 735(2018), p. 131.

J. Zhao, B. Jiang, Y. Yuan, Q.H. Wang, M. Yuan, A.T. Tang, G.S. Huang, D.F. Zhang, and F.S. Pan, Understanding the enhanced ductility of Mg-Gd with Ca and Zn microalloying by slip trace analysis, J. Mater. Sci. Technol., 95(2021), p. 20.

Y.B. Chun and C.H.J. Davies, Investigation of prism 〉a〈 slip in warm-rolled AZ31 alloy, Metall. Mater. Trans. A, 42(2011), p. 4113.

S. Nandy, S.P. Tsai, L. Stephenson, D. Raabe, and S. Zaefferer, The role of Ca, Al and Zn on room temperature ductility and grain boundary cohesion of magnesium, J. Magnes. Alloys, 9(2021), No. 5, p. 1521.

R.H. Li, F.S. Pan, B. Jiang, H.W. Dong, and Q.S. Yang, Effect of Li addition on the mechanical behavior and texture of the as-extruded AZ31 magnesium alloy, Mater. Sci. Eng. A, 562(2013), p. 33.

J. Zhao, B. Jiang, A.T. Tang, Y.F. Chai, B. Liu, H.R. Sheng, T.H. Yang, G.S. Huang, D.F. Zhang, and F.S. Pan, Deformation behavior and texture evolution in an extruded Mg-Li sheet with non-basal texture during tensile deformation, Mater. Charact., 159(2020), art. No. 110041.

D.B. Xia, G.S. Huang, Q.Y. Deng, B. Jiang, S.S. Liu, and F.S. Pan, Influence of stress state on microstructure evolution of AZ31 Mg alloy rolled sheet during deformation at room temperature, Mater. Sci. Eng. A, 715(2018), p. 379.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. U1764253, U2037601, U1910213, 51971044, and 52001037) and the Qinghai Science and Technology Program, China (No. 2018-GX-A1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhao, J., Jiang, B., Wang, Q. et al. Effects of Li addition on the microstructure and tensile properties of the extruded Mg-1Zn-xLi alloy. Int J Miner Metall Mater 29, 1380–1387 (2022). https://doi.org/10.1007/s12613-021-2340-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2340-0