Abstract

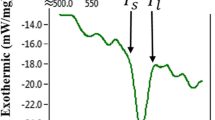

An Al–Ti–Cu–Si solid–liquid dual-phase alloy that exhibits good wettability and appropriate interfacial reaction with SiC at 500–600°C was designed for SiC–metal joining. The microstructure, phases, differential thermal curves, and high-temperature wetting behavior of the alloy were analyzed using scanning electron microscopy, X-ray diffraction analysis, differential scanning calorimetry, and the sessile drop method. The experimental results show that the 76.5Al–8.5Ti–5Cu–10Si alloy is mainly composed of Al–Al2Cu and Al–Si hypoeutectic low-melting-point microstructures (493–586°C) and the high-melting-point intermetallic compound AlTiSi (840°C). The contact angle, determined by high-temperature wetting experiments, is approximately 54°. Furthermore, the wetting interface is smooth and contains no obvious defects. Metallurgical bonding at the interface is attributable to the reaction between Al and Si in the alloy and ceramic, respectively. The formation of the brittle Al4C3 phase at the interface is suppressed by the addition of 10wt% Si to the alloy.

Similar content being viewed by others

References

G.W. Liu, M.L. Muolo, F. Valenza, and A. Passerone, Survey on wetting of SiC by molten metals, Ceram. Int., 36(2010, No. 4, 1177.

X.G. Chen, J.C. Yan, S.C. Ren, J.H. Wei, and Q. Wang, Ultrasonic-assisted brazing of SiC ceramic to Ti–6Al–4V alloy using a novel AlSnSiZnMg filler metal, Mater. Lett., 105(2013, No. 1, 120.

Y. Zhang, D. Fang, Z.Y. He, and X.C. Chen, Progress in joining ceramics to metals, J. Iron Steel Res. Int., 13(2006, No. 2, 1.

J.K. Li, L. Liu, Y.T. Wu, W.L. Zhang, and W.B. Hu, A high temperature Ti–Si eutectic braze for joining SiC, Mater. Lett., 62(2008, No. 17–18), 3135.

Y.H. Yau, A. Hussain, R.K. Lalwani, H.K. Chan, and N. Hakimi, Temperature distribution study during the friction stir welding process of Al2024–T3 aluminum alloy, Int. J. Miner. Metall. Mater., 20(2013, No. 8, 779.

A.A. Nia and A. Shirazi, Effects of different friction stir welding conditions on the microstructure and mechanical properties of copper plates, Int. J. Miner. Metall. Mater., 23(2016, No. 7, 799.

G.F. Sui, J.S. Li, H.W. Li, F. Sun, T.B. Zhang, and H.Z. Fu, Investigation on the explosive welding mechanism of corrosion-resisting aluminum and stainless steel tubes through finite element simulation and experiments, Int. J. Miner. Metall. Mater., 19(2012, No. 2, 151.

G. Çam and M. Koçak, Progress in joining of advanced materials, Int. Mater. Rev., 43(1998, No. 1, 1.

J.Y. Kim, M. Engelhard, J.P. Choi, and K.S. Weil, Effects of atmospheres on bonding characteristics of silver and alumina, Int. J. Hydrogen Energy, 33(2008, No. 14, 4001.

A.K. Jadoon, B. Ralph, and P.R. Hornsby, Metal to ceramic joining via a metallic interlayer bonding technique, J. Mater. Process. Technol., 152(2004, No. 3, 257.

W.F. Ding, J.H. Xu, Z.Z. Chen, H.H. Su, and Y.C. Fu, Brazed joints of CBN grains and AISI 1045 steel with AgCuTi–TiC mixed powder as filler materials, Int. J. Miner. Metall. Mater., 18(2011, No. 6, 717.

Y. Liu, Z.R. Huang, and X.J. Liu, Joining of sintered silicon carbide using ternary Ag–Cu–Ti active brazing alloy, Ceram. Int., 35(2009, No. 8, 3479.

M. Singh, T. Matsunaga, H.T. Lin, R. Asthana, and T. Ishikawa, Microstructure and mechanical properties of joints in sintered SiC fiber-bonded ceramics brazed with Ag–Cu–Ti alloy, Mater. Sci. Eng. A, 557(2012, 69.

H.J. Liu, J.C. Feng, and Y.Y. Qian, Microstructure and strength of SiC/TiAl joints brazed by Ag–Cu–Ti filler metal, J. Mater. Sci. Lett., 19(2000, No. 14, 1241.

J.K. Li, L. Liu, Y.T. Wu, Z.B. Li, W.L. Zhang, and W.B. Hu, Microstructure of high temperature Ti-based brazing alloys and wettability on SiC ceramic, Mater. Des., 30(2009, No. 2, 275.

J.G. Li, Wettability of silicon carbide by liquid silver and binary silver–silicon alloy, Mater. Lett., 18(1994, No. 5–6), 291.

A. Tsoga, S. Ladas, and P. Nikolopoulos, Correlation between the oxidation state of a–SiC and its wettability with non-reactive (Sn) or reactive (Ni) metallic components and their binary Si-alloys, Acta Mater., 45(1997, No. 9, 3515.

X.S. Cong, P. Shen, Y. Wang, and Q.C. Jiang, Wetting of polycrystalline SiC by molten Al and Al–Si alloys, Appl. Surf. Sci., 317(2014, 140.

M. Zeren and E. Karakulak, Influence of Ti addition on the microstructure and hardness properties of near-eutectic Al–Si alloys, J. Alloys Compd., 450(2008, No. 1–2), 255.

T. Gao, P.T. Li, Y.G. Li, and X.F. Liu, Influence of Si and Ti contents on the microstructure, microhardness and performance of TiAlSi intermetallics in Al–Si–Ti alloys, J. Alloys Compd., 509(2011, No. 31, 8013.

Q. Luo, Q. Li, J.Y. Zhang, S.L. Chen, and K.C. Chou, Experimental investigation and thermodynamic calculation of the Al–Si–Ti system in Al-rich corner, J. Alloys Compd., 602(2014, 58.

X.S. Cong, Wettability of Silicon Carbide by Molten Aluminum or Aluminum Alloys and Their Interfacial Microstructures [Dissertation], Jilin University, Changchun, 2014, p. 24.

V. Laurent, C. Rado, and N. Eustathopoulos, Wetting kinetics and bonding of Al and Al alloys on a–SiC, Mater. Sci. Eng. A, 205(1996, No. 1–2), 1.

A. Bahrami, M.I. Pech-Canul, C.A. Gutierrez, and N. Soltani, Effect of rice-husk ash on properties of laminated and functionally graded Al/SiC composites by one-step pressureless infiltration, J. Alloys Compd., 644(2015, 256.

S. Bao, K. Tang, A. Kvithyld, T. Engh, and M. Tangstad, Wetting of pure aluminium on graphite, SiC and Al2O3 in aluminium filtration, Trans. Nonferrous Met. Soc. China, 22(2012, No. 8, 1930.

B. Drevet, S. Kalogeropoulou, and N. Eustathopoulos, Wettability and interfacial bonding in Au–Si/SiC system, Acta Metall. Mater., 41(1993, No. 11, 3119.

S. Kalogeropoulou, L. Baud, and N. Eustathopoulos, Relationship between wettability and reactivity in Fe/SiC system, Acta Metall. Mater., 43(1995, No. 3, 907.

M. Sabisch, P. Krüger, and J. Pollmann, Ab initio calculations of structural and electronic properties of 6H–SiC(0001) surfaces, Phys. Rev. B., 55(1997, No. 16, 10561.

J.C. Lee, J.Y. Byun, S.B. Park, and H.I. Lee, Prediction of Si contents to suppress the formation of Al4C3 in the SiCp/Al composite, Acta Mater., 46(1998, No. 5, 1771.

A.C. Ferro and B. Derby, Wetting behaviour in the Al–Si/SiC system: interface reactions and solubility effects, Acta Metall. Mater., 43(1995, No. 8, 3061.

Acknowledgments

This work was financially supported by the High-Tech Research and Development Program of China (No. SS2013AA031305) and the Key Technologies R&D Program of Tianjin (No. 12ZCDGGX49100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, Cd., Ma, Rn., Wang, W. et al. Microstructure and properties of an Al–Ti–Cu–Si brazing alloy for SiC–metal joining. Int J Miner Metall Mater 24, 557–565 (2017). https://doi.org/10.1007/s12613-017-1437-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1437-y