Abstract

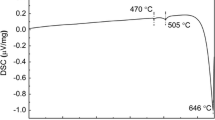

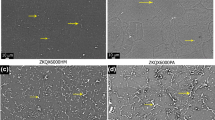

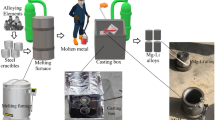

Mg–8Li–3Al+xCe alloys (x = 0.5wt%, 1.0wt%, and 1.5wt%) were prepared through a casting route in an electric resistance furnace under a controlled atmosphere. The cast alloys were characterized by X-ray diffraction, optical microscopy, scanning electron microscopy, and energy-dispersive X-ray spectroscopy. The corrosion behavior of the as-cast Mg–8Li–3Al+xCe alloys were studied under salt spray tests in 3.5wt% NaCl solution at 35°C, in accordance with standard ASTM B–117, in conjunction with potentiodynamic polarization (PDP) tests. The results show that the addition of Ce to Mg–8Li–3Al (LA83) alloy results in the formation of Al2Ce intermetallic phase, refines both the α-Mg phase and the Mg17Al12 intermetallic phase, and then increases the microhardness of the alloys. The results of PDP and salt spray tests reveal that an increase in Ce content to 1.5wt% decreases the corrosion rate. The best corrosion resistance is observed for the LA83 alloy sample with 1.0wt% Ce.

Similar content being viewed by others

References

T. Wang, M.L. Zhang, and R.Z. Wu, Microstructure and properties of Mg–8Li–1Al–1Ce alloy, Mater. Lett., 62(2008), No. 12-13, p. 1846.

P. Crawford, R. Barrosa, J. Mendez, J. Foyos, and O.S. Es-Said, On the transformation characteristics of LA141A (Mg–Li–Al) alloy, J. Mater. Process. Technol., 56(1996), No. 1-4, p. 108.

H. Haferkamp, M. Niemeyer, R. Boehm, U. Holzkamp, C. Jaschik, and V. Kaese, Development, processing and applications range of magnesium lithium alloys, Mater. Sci. Forum, 350-351(2000), No. 7, p. 31.

T. Wang, M.L. Zhang, Z.Y. Niu, and B. Liu, Influence of rare earth elements on microstructure and mechanical properties of Mg−Li alloys, J. Rare Earths, 24(2006), No. 6, p. 797.

J.A. Jensen and L.S. Chumbley, Processing and mechanical properties of magnesium−lithium composites containing steel fibers, Metall. Mater. Trans. A, 29(1998), p. 863.

H. Takuda, S. Kikuchi, T. Tsukada, K. Kubota, and N. Hatta, Effect of strain rate on deformation behaviour of a Mg–8.5Li–1Zn alloy sheet at room temperature, Mater. Sci. Eng. A, 271(1999), No. 1-2, p. 251.

H. Takuda, T. Enami, K. Kubota, and N. Hatta, The formability of a thin sheet of Mg–8.5Li–1Zn alloy, J. Mater. Process. Technol., 101(2000), No. 1-3, p. 281.

N. Hara, Y. Kobayashi, D. Kagaya, and N. Akao, Formation and breakdown of surface films on magnesium and its alloys in aqueous solutions, Corros. Sci., 49(2007), No. 1, p. 166.

J.H. Nordlien, K. Nisancioglu, S. Ono, and N. Masuko, Morphology and structure of water-formed oxides on ternary MgAl alloys, J. Electrochem. Soc., 144(1997), No. 2, p. 461.

J.L. Wang, R.L. Liao, L.D. Wang, Y.M. Wu, Z.Y. Cao, and L.M. Wang, Investigations of the properties of Mg−5Al−0.3Mn−xCe (x=0−3,wt.%) alloys, J. Alloys Compd., 477(2009), No. 1, p. 341.

M.L. Zhang, R.Z. Wu, and T. Wang, Microstructure and mechanical properties of Mg−8Li−(0−3)Ce alloys, J. Mater. Sci., 44(2009), No. 5, p. 1237.

H. Yan, R.S. Chen, and E.H. Han, Microstructures and mechanical properties of cold rolled Mg−8Li and Mg−8Li−2Al−2RE alloys, Trans. Nonferrous Met. Soc. China, 20(2010), Suppl. 2, p. s550.

B. Liu, M.L. Zhang, and R.Z. Wu, Influence of Ce on microstructure and mechanical properties of LA141 alloys, Trans. Nonferrous Met. Soc. China, 17(2007), Suppl. 1, p. s376.

Z.K. Qu, L.B. Wu, R.Z. Wu, J.H. Zhang, M.L. Zhang, and B. Liu, Microstructures and tensile properties of hot extruded Mg–5Li–3Al–2Zn–xRE (rare earths) alloys, Mater. Des., 54(2014), p. 792.

Y.W. Song, D.Y. Shan, R.S. Chen, and E. Han, Corrosion characterization of Mg–8Li alloy in NaCl solution, Corros. Sci., 51(2009), No. 5, p. 1087.

L.B. Wu, X.H. Liu, R.Z. Wu, C.L. Cui, J.H. Zhang, and M.L. Zhang, Microstructure and tensile properties of Mg−Li−Al− Zn based alloys with Ce addition, Trans. Nonferrous Met. Soc. China, 22(2012), No. 4, p. 779.

ASTM B117–11, Standard Practice for Operating Salt Spray (Fog) Apparatus, ASTM International, West Conshohocken, 2011.

ASTM G31–72, Standard Practices for Laboratory Immersion Corrosion Testing of Metals, ASTM International, West Conshohocken, 2004.

L.B. Wu, C.L. Cui, R.Z. Wu, J.Q. Li, H.B. Zhan, M.L. Zhang, Effects of Ce-rich RE additions and heat treatment on the microstructure and tensile properties of Mg–Li–Al–Zn-based alloy, Mater. Sci. Eng. A, 528(2011), No. 4-5, p. 2174.

M. Easton and D. StJohn, Grain refinement of aluminum alloys: Part II. Confirmation of, and a mechanism for, the solute paradigm, Metall. Mater. Trans. A, 30(1999), No. 6, p. 1625.

H.H. Uhlig and R.W. Revie, Corrosion and Corrosion Control, 3rd Ed., John Wiley and Sons, New York, 1985.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manivannan, S., Dinesh, P., Mahemaa, R. et al. Corrosion behavior of as-cast Mg–8Li–3Al+xCe alloy in 3.5wt% NaCl solution. Int J Miner Metall Mater 23, 1196–1203 (2016). https://doi.org/10.1007/s12613-016-1339-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1339-4