Abstract

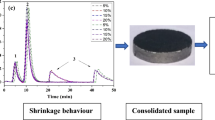

An FeMo-alloy-doped β-SiAlON (FeMo/β-SiAlON) composite was fabricated via a reaction-bonding method using raw materials of Si, Al2O3, AlN, FeMo, and Sm2O3. The effects of FeMo on the microstructure and mechanical properties of the composite were investigated. Some properties of the composite, including its bending strength at 700°C and after oxidization at 700°C for 24 h in air, thermal shock resistance and corrosion resistance to molten aluminum, were also evaluated. The results show that the density, toughness, bending strength, and thermal shock resistance of the composite are obviously improved with the addition of an FeMo alloy. In addition, other properties of the composite such as its high-temperature strength and oxidized strength are also improved by the addition of FeMo alloy, and its corrosion resistance to molten aluminum is maintained. These findings indicate that the developed FeMo/β-SiAlON composite exhibits strong potential for application to molten aluminum environments.

Similar content being viewed by others

References

K.H. Jack, Sialons and related nitrogen ceramics, J. Mater. Sci., 11(1976), No. 6, p. 1135.

A.R. Bahramian, M. Kokabi, and F.P. Soorbaghi, Carbon fiber reinforced β-SiAlON for ultra high temperature ablative heat shields, Int. J. Appl. Ceram. Technol., 10(2013), No. 2, p. 203.

F. Çaliskan, Z. Tatli, A. Genson, and S. Hampshire, Pressureless sintering of β-SiAlON ceramic compositions using fluorine and oxide additive system, J. Eur. Ceram. Soc., 32(2012), No. 7, p. 1337.

X.M. Hou, X. Lu, B. Peng, B.J. Zhao, M. Zhang, and K.C. Chou, A new approach to interpreting the parabolic and non-parabolic oxidation behaviour of hot-pressed β-SiAlON ceramics, Corros. Sci., 58(2012), p. 278.

H. Hyuga, K. Yoshida, N. Kondo, H. Kita, J. Sugai, H. Okano, and J. Tsuchida, Fabrication of pressureless sintered dense β-SiAlON via a reaction-bonding route with ZrO2 addition, Ceram. Int., 35(2009), No. 5, p. 1927.

F.L. Riley, Silicon nitride and related materials, J. Am. Ceram. Soc., 83(2000), No. 2, p. 245.

V.A. Izhevskiy, L.A. Genova, J.C. Bressiani, and F. Aldinger, Progress in SiAlON ceramics, J. Eur. Ceram. Soc., 20(2000), No. 13, p. 2275.

T. Ekström and M. Nygren, SiAlON ceramics, J. Am. Ceram. Soc., 75(1992), No. 2, p. 259.

H. Banno, T. Asaka, and K. Fukuda, Electron density distribution and disordered crystal structure of 8H-SiAlON, Si3−xAl1+xOxN5−x (x~2.2), J. Solid State Chem., 213(2014), p. 169.

B. Joshi, H.H. Lee, H. Wang, Z.Y. Fu, K. Niihara, and S.W. Lee, The effect of different rare earth oxides on mechanical and optical properties of hot pressed α/β-sialon ceramics, J. Eur. Ceram. Soc., 32(2012), No. 13, p. 3603.

I. Ganesh, N. Thiyagarajan, D.C. Jana, Y.R. Mahajan, and G. Sundararajan, Influence of chemical composition and Y2O3 on sinterability, dielectric constant, and CTE of β-SiAlON, J. Am. Ceram. Soc., 91(2008), No. 1, p. 115.

O. Eser and S. Kurama, A comparison of sintering techniques using different particle sized β-SiAlON powders, J. Eur. Ceram. Soc., 32(2012), No. 7, p. 1343.

J.F. Yang, G.J. Zhang, J.H. She, T. Ohji, and S. Kanzaki, Improvement of mechanical properties and corrosion resistance of porous β-SiAlON ceramics by low Y2O3 additions, J. Am. Ceram. Soc., 87(2004), No. 9, p. 1714.

T. Ekström, P.O. Käll, M. Nygren, and P.O. Olsson, Dense single-phase β-sialon ceramics by glass-encapsulated hot isostatic pressing, J. Mater. Sci., 24(1989), No. 5, p. 1853.

Z.H. Huang, J.Z. Yang, Y.G. Liu, M.H. Fang, J.T. Huang, H.R. Sun, and S.F. Huang, Novel sialon-based ceramics toughened by ferro-molybdenum alloy, J. Am. Ceram. Soc., 95(2012), No. 3, p. 859.

J.Z. Yang, Z.H. Huang, M.H. Fang, Y.G. Liu, J.T. Huang, and J.H. Hu, Preparation and mechanical properties of Fe/Mo-Sialon ceramic composites, Scripta Mater., 61(2009), No. 6, p. 632.

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall, A critical evaluation of indentation techniques for measuring fracture toughness: I. Direct crack measurements, J. Am. Ceram. Soc., 64(1981), No. 9, p. 533.

N.C. Acikbas, S. Tegmen, S. Ozcan, and G. Acikbas, Thermal shock behaviour of a:β-SiAlON-TiN composites, Ceram. Int., 40(2014), No. 2, p. 3611.

P. Pettersson, M. Johnsson, and Z. Shen, Parameters for measuring the thermal shock of ceramic materials with an indentation-quench method, J. Eur. Ceram. Soc., 22(2002), No. 11, p. 1883.

P. Pettersson, Z. Shen, M. Johnsson, and M. Nygren, Thermal shock properties of β-sialon ceramics, J. Eur. Ceram. Soc., 22(2002), No. 8, p. 1357.

M. Collin and D. Rowcliffe, Analysis and prediction of thermal shock in brittle materials, Acta Mater., 48(2000), No. 8, p. 1655.

W. Song, J.L. Sun, Y. Li, and J.H. Chen, Effect of synthesis process on phase composition and structure of ferro-silicon nitride, J. Chin. Ceram. Soc., 38(2010), No. 7, p. 1281.

S.J. Zhu, J.L. Sun, and Y.R. Hong, Computer simulation of flash combustion synthesis of ferro-silicon nitride, Refractories, 39(2005), No. 4, p. 274.

F. Weitzer and J.C. Schuster, Phase diagrams of the ternary systems Mn, Fe, Co, Ni-Si-N, J. Solid State Chem., 70(1987), No. 2, p. 178.

S. Singh, M.M. Godkhindi, R.V. Krishnarao, and B.S. Murty, Synthesis of Si3N4-MoSi2 in situ composite from mechanically activated (Mo+Si3N4) powders, J. Alloys Compd., 381(2004), No. 1–2, p. 254.

R.M. Spriggs, Expression for effect of porosity on elastic modulus of polycrystalline refactory materials, particularly aluminium oxide, J. Am. Ceram. Soc., 44(1961), No. 12, p. 628.

L.S. Wang, Z.F. Zhang, Y. Fan, and B.Y. Yin, Influence of sintering aids on pressureless sintering of sialon ceramics, Chin. J. Nonferrous Met., 11(2001), No. 3, p. 386.

L.S. Wang, Y.C. Wang, Y. Fan, and F. Wu, The pressureless sintering of sialon ceramics, J. Cent. South Univ. Technol. Nat. Sci., 32(2001), No. 3, p. 277.

R.M. German, P. Suri, and S.J. Park, Review: liquid phase sintering, J. Mater. Sci., 44(2009), No. 1, p. 1.

W.D. Kingery, H.K. Bowen, and D.R. Uhlmann, Introduction to Ceramics, Wiley-Interscience, New York, USA, 1976.

M. Madhan and G. Prabhakaran, Self-healing ability of structural ceramics: a review, Trends Intell. Rob. Autom. Manuf., 330(2012), p. 466.

W. Nakao, S. Mori, J. Nakamura, K. Takahashi, K. Ando, and M. Yokouchi, Self-crack-healing behavior of mullite/SiC particle/SiC whisker multi-composites and potential use for ceramic springs, J. Am. Ceram. Soc., 89(2006), No. 4, p. 1352.

Y.H. Zhang, L. Edwards, and W.J. Plumbridge, Crack healing in a silicon nitride ceramic, J. Am. Ceram. Soc., 81(1998), No. 7, p. 1861.

Y.H. Zhang and L. Edwards, Cyclic fatigue crack growth behaviour of silicon nitride at 1400°C, Mater. Sci. Eng. A, 256(1998), No. 1–2, p. 144.

D.P.H. Hasselman, Unified theory of thermal shock fracture initiation and crack propagation in brittle ceramics, J. Am. Ceram. Soc., 52(1969), No. 11, p. 600.

Y. Yu, J.G. Cheng, L. Wan, B. Liang, and J. Liu, Fabrication and properties of Al/AlN composites by a pressureless infiltration process, Acta Mater. Compos. Sin., 28(2011), No. 6, p. 166.

Y.L. Shen, Thermal expansion of metal-ceramic composites: a three-dimensional analysis, Mater. Sci. Eng. A, 252(1998), No. 2, p. 269.

C. dos Santos, S. Ribeiro, K. Strecker, and C.R.M. da Silva, Characterization of Si3N4-Al interface after corrosion tests, Cerâmica, 49(2003), No. 312, p. 223.

L. Mouradoff, P. Tristant, J. Desmaison, J.C. Labbe, M. Desmaison-Brut, and R. Rezakhanlou, Interaction between liquid aluminium and non-oxide ceramics (AlN, Si3N4, SiC), Key Eng. Mater., 113(1996), p. 177.

G.C. Li, X.S. Ning, K.X. Chen, and H.P. Zhou, Interaction of Si3N4 ceramics and liquid aluminum at interface without oxidation, Rare Met. Mater. Eng., 38(2009), No. z2, p. 186.

C. Chatillon, L. Coudurier, and N. Eustathopoulos, Stability of oxide films on liquid metals under vacuum: influence on wetting of metals on ceramic surfaces, Mater. Sci. Forum, 251–254(1997), p. 701.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Yj., Yu, Hl., Jin, Hy. et al. Properties of a reaction-bonded β-SiAlON ceramic doped with an FeMo alloy for application to molten aluminum environments. Int J Miner Metall Mater 22, 530–536 (2015). https://doi.org/10.1007/s12613-015-1103-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1103-1