Abstract

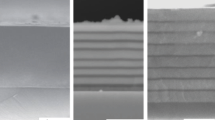

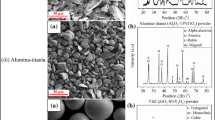

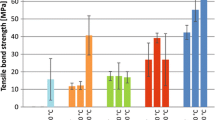

Ceramic materials were investigated as thermal barrier coatings and electrolytes. Electrophoretic deposition (EPD) and physical vapor deposition (PVD) were employed to fabricate samples, and the mechanical properties and microstructure were examined by nanoindentation and microscopy, respectively. Yttria-stabilized zirconia/alumina (YSZ/Al2O3) composite coatings, a candidate for thermal barrier coatings, yield a kinky, rather than smooth, load-displacement curve. Scanning electron microscope (SEM) examination reveals that the kinky curve is because of the porous microstructure and cracks are caused by the compression of the indenter. Li0.34La0.51TiO2.94 (LLTO) on Si/SrRuO3 (Si/SRO) substrates, an ionic conductor in nature, demonstrates electronic performance. Although SEM images show a continuous and smooth microstructure, a close examination of the microstructure by transmission electron microscopy (TEM) reveals that the observed spikes indicate electronic performance. Therefore, we can conclude that ceramic coatings could serve multiple purposes but their properties are microstructure-dependent.

Similar content being viewed by others

References

X.Q. Cao, R. Vassen, and D. Stoever, Ceramic materials for thermal barrier coatings, J. Eur. Ceram. Soc., 24(2004), No. 1, p. 1.

S.M. Naga, Advanced in Ceramic Matrix Composite, Woodhead Publishing Limited, Cambridge, 2014, p. 524.

G.H. Wang, Y. Zhang, D.H. Zhang, and J.P. Fan, Design and calculation of low infrared transmittance and low emissivity coatings for heat radiative applications, Int. J. Miner. Metall. Mater., 19(2012), No. 2, p. 179.

S. Banerjee and A.K. Tyagi, Functional Materials: Preparation, Processing and Applications, Elsevier, London, 2012, p. 639.

W.C. Oliver and G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 7(1992), No. 6, p. 1564.

J.A. Thompson and T.W. Clyne, The effect of heat treatment on the stiffness of zirconia top coats in plasma-sprayed TBCs, Acta Mater., 49(2001), No. 9, p. 1565.

J. Malzbender and R.W. Steinbrech, Determination of the stress-dependent stiffness of plasma-sprayed thermal barrier coatings using depth-sensitive indentation, J. Mater. Res., 18(2003), No. 8, p. 1975.

E. Lugscheider, K. Bobzin, A. Bärwulf, and A. Etzkorn, Mechanical properties of EB-PVD-thermal barrier coatings by nanoindentation, Surf. Coat. Technol., 138(2001), No. 1, p. 9.

R. Ghasemi, R. Shoja-Razavi, R. Mozafarinia, and H. Jamali, Comparison of microstructure and mechanical properties of plasma-sprayed nanostructured and conventional yttria stabilized zirconia thermal barrier coatings, Ceram. Int., 39(2013), No. 8, p. 8805.

P. Carpio, E. Rayón, L. Pawłowski, A. Cattini, R. Benavente, E. Bannier, M.D. Salvador, and E. Sánchez, Microstructure and indentation mechanical properties of YSZ nanostructured coatings obtained by suspension plasma spraying, Surf. Coat. Technol., 220(2013), p. 237.

D.R. Clarke and C.G. Levi, Materials design for the next generation thermal barrier coatings, Annu. Rev. Mater. Res., 33(2003), p. 383.

M.J. Pindera, J. Aboudi, and S.M. Arnold, NASA/TM-2003-210803 Analysis of Plasma-Sprayed Thermal Barrier Coatings with Homogeneous and Heterogeneous Bond Coats under Spatially Uniform Cyclic Thermal Loading, 2003.

Y. Inaguma, C. Liquan, M. Itoh, T. Nakamura, T. Uchida, H. Ikuta, and M. Wakihara, High ionic conductivity in lithium lanthanum titanate, Solid State Commun., 86(1993), No. 10, p. 689.

Y. Inaguma, J.D. Yu, Y.J. Shan, M. Itoh, and T. Nakamuraa, The effect of the hydrostatic pressure on the ionic conductivity in a perovskite lanthanum lithium titanate, J. Electrochem. Soc., 142(1995), No. 1, p. L8.

H. Zhang, X.B. Liu, Y. Qi, and V. Liu, On the La2/3−x Li3x TiO3/Al2O3 composite solid-electrolyte for Li-ion conduction, J. Alloys Compd., 577(2013), p. 57.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, X. Effect of microstructure on the mechanical, thermal, and electronic property measurement of ceramic coatings. Int J Miner Metall Mater 21, 1127–1131 (2014). https://doi.org/10.1007/s12613-014-1018-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-1018-2