Abstract

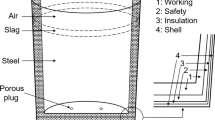

A three-dimensional computational fluid dynamics (CFD) model was developed to simulate a 150-t top-blown converter. The effect of different lance heights on the cavity shape was investigated using the volume of fluid (VOF) method. Numerical simulation results can reflect the actual molten bath surface waves impinged by the supersonic oxygen jets. With increasing lance height, the cavity depth decreases, and the cavity area, varying like a parabola, increases and then decreases. The cavity area maximizes at the lance height of 1.3 m. Under the three different lance heights simulated in this study, all of the largest impact velocities at the molten bath surface are between 50 m/s and 100 m/s.

Similar content being viewed by others

Abbreviations

- c p :

-

Heat capacity

- d t :

-

Throat diameter

- f σ :

-

Surface tension force per unit volume

- \(\vec g\) :

-

Vector of gravitational acceleration

- h :

-

Cavity depth formed by the impinging gas

- H :

-

Lance height

- M :

-

Molecular weight

- P :

-

Pressure of gas

- P amb :

-

Ambient pressure

- P 0 :

-

Oxygen stagnation pressure

- R :

-

Gas constant

- T :

-

Temperature

- \(\vec u\) :

-

Velocity vector

- x :

-

Distance of the smallest control volume

- α :

-

Volume fraction

- ɛ :

-

Turbulence dissipation

- κ:

-

Turbulence kinetic energy

- µ:

-

Molecular viscosity

- µe :

-

Effective molecular viscosity

- µt :

-

Turbulent eddy molecular viscosity

- θ :

-

Inclination angle of lance nozzles

- ρ :

-

Density

- τ :

-

Time

- l:

-

Molten liquid

- g:

-

Gas

- i, j :

-

i and j direction in the axis, respectively

- ox, st, sl:

-

Oxygen, steel, slag, respectively

References

J. Feng, Y.P. Bao, X. Wu, and H. Cui, Mathematical model of deoxidization with post stirring in a combined blowing converter, Int. J. Miner. Metall. Mater., 17(2010), No. 5, p. 541.

G.H. Li, B. Wang, Q. Liu, X.Z. Tian, R. Zhu, L.N. Hu, and G.G. Cheng, A process model for BOF process based on bath mixing degree, Int. J. Miner. Metall. Mater., 17(2010), No. 6, p. 715.

Y. Higuchi and Y. Tago, Effect of lance design on jet behavior and spitting rate in top blown process, ISIJ Int., 41(2001), No. 12, p. 1454.

J. Solórzano-López, R. Zenit, and M.A. Ramírez-Argáez, Mathematical and physical simulation of the interaction between a gas jet and a liquid free surface, Appl. Math. Model, 35(2011), No. 10, p. 4991.

A. Nordquist, N. Kumbhat, L. Jonsson, and P. Jönsson, The effect of nozzle diameter, lance height and flow rate on penetration depth in a top-blown water model, Steel Res. Int.,77(2006), No. 2, p. 82.

B.K. Li, H.B. Yin, C.Q. Zhou, and F. Tsukihashi, Modeling of three-phase flows and behavior of slag/steel interface in an argon gas stirred ladle, ISIJ Int., 48(2008), No. 12, p. 1704.

M. Ersson, L. Höglund, A. Tilliander, L. Jonsson, and P. Jönsson, Dynamic coupling of computational fluid dynamics and thermodynamics software: applied on a top blown converter, ISIJ Int., 48(2008), No. 2, p. 147.

S.C. Koria and K.W. Lange, Penetrability of impinging gas jets in molten steel bath, Steel Res., 58(1987), No. 9, p. 421.

Y. Tago and Y. Higuchi, Fluid flow analysis of jets from nozzles in top blown process, ISIJ Int., 43(2003), No. 2, p. 209.

O. Olivares, A. Elias, R. Sanchez, M. Diaz-Cruz, and R.D. Morales, Physical and mathematical models of gas-liquid fluid dynamics in LD converters, Steel Res., 73(2002), No. 2, p. 44.

M. Alam, J. Naser, G. Brooks, and A. Fontana, A computational fluid dynamics model of shrouded supersonic jet impingement on a water surface, ISIJ Int., 52(2012), No. 6, p. 1026.

J. Szekely and S. Asai, Turbulent fluid flow phenomena in metals processing operations: mathematical description of the fluid flow field in a bath caused by an impinging gas jet, Metall. Trans., 5(1974), p. 463.

N. Asahara, K. Naito, I. Kitagawa, M. Matsuo, M. Kumakura, and M. Iwasaki, Fundamental study on interaction between top blown jet and liquid bath, Steel Res. Int., 82(2011), No. 5, p. 587.

Z.F. Yuan and Y.F. Fan, The Technology of Oxygen Lance in Steelmaking, Metallurgy Industry Press, Beijing, 2007, p. 89.

F. Qian, R. Muthasaran, and B. Farouk, Studies of interface deformations in single- and multi-layered liquid baths due to an impinging gas jet, Metall. Mater. Trans. B, 27(1996), No. 6, p. 911.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, K., Zhu, R., Gao, W. et al. Simulation of three-phase flow and lance height effect on the cavity shape. Int J Miner Metall Mater 21, 523–530 (2014). https://doi.org/10.1007/s12613-014-0938-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0938-1