Abstract

Functionalizing foods involve discovering and integrating new candidate health-promoting bacteria into the food matrix. This study aimed (i) to reveal the probiotic potential of autochthonous Lacticaseibacillus paracasei AD22 by a series of in vitro tests and molecular characterization and (ii) to evaluate its application to the matrix of brined white cheese, which is the most common cheese in Türkiye, in terms of survival and stress response. To evaluate in vitro probiotic characteristics, L. paracasei AD22 was exposed to functional, technological, and safety tests. Pilot scale production was conducted to integrate L. paracasei AD22 into the brined white cheese matrix. The expression levels of stress-related genes (dnaK, groES, ftsH, argH, and hsp20) were detected by reverse-transcriptase polymerase chain reaction to determine the transcriptional stress response during ripening. The presence of genes encoding stress-related proteins was determined by whole-genome sequence analysis using a subsystem approach; the presence of antibiotic resistance and virulence genes was determined by ResFinder4.1 and VirulenceFinder 2.0 databases. The BAGEL4 database determined the presence of bacteriocin clusters. L. paracasei AD22 was found to survive in pH 2 and medium with 12% NaCl and did not cause hemolysis. Adhesion of the strain to Caco2 cells was 76.26 ± 4.81% and it had coaggregation/autoaggregation properties. It was determined that L. paracasei AD22 exceeded 7 log cfu/g in the cheese matrix at the end of the ripening period. Total mesophilic aerobes decreased in the cheese inoculated with L. paracasei AD22 after the 45th day of ripening. While hsp20 and groES genes were downregulated during ripening, argH was upregulated. Both downregulation and upregulation were observed in dnaK and ftsH. Fold changes indicating the expression levels of dnaK, groES, ftsH, argH, and hsp20 genes were not statistically significant during ripening (p > 0.05). Whole-genome sequence profiles revealed that the strain did not contain antibiotic and virulence genes but bacteriocin clusters encoding Enterolysin A (Class III bacteriocin), Carnosine CP52 (class II bacteriocin), Enterocin X beta chain (Class IIc bacteriocin), and the LanT region. Subsystems approach manifested that the most functional part of the genomic distribution belonged to metabolism, protein processing, and stress response functions. The study findings highlight that L. paracasei AD22 will provide biotechnological innovation as a probiotic adjunct because it contains tolerance factors and probiotic characteristics to produce new functional foods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recent scientific research has focused on selecting and characterizing new species and more specific probiotic strains that survive in the food matrix and contain functional properties [1, 2]. In particular, the isolation of new probiotic strains from traditional food products such as kefir grains, cheese, fermented olives, meat products, and the possible usage of new isolates in food production has been taken into consideration [3,4,5,6,7]. Probiotics are part of functional foods and are proposed as one of the main mechanisms providing beneficial effects such as protecting mucosal barrier, preventing the proliferation of pathogens, synthesizing immunomodulatory the cellular metabolites in the host [8].

Viability in the product matrix during food production, distribution, and storage is a factor assigning the efficacy of probiotics and starter cultures. Cheese is described as a suitable food matrix for the delivery of probiotics; hence, studies have emphasized the positive effect of probiotic addition on the physicochemical, microbiological, and sensory properties of cheese [9, 10]. Cheese is a decent option for probiotics with advantages in terms of better buffering capacity, less water activity, and low storage temperature over other fermented milk products [11]. However, a strain designated as a starter culture, probiotic, or adjunct culture must be present in sufficient quantities to meet industrial requirements. High survival stability in the cheese production process and before inclusion is important in determining probiotic properties [11]. Therefore, it is essential to reveal the stress response of lactic acid bacteria (LAB) and the molecular regulatory mechanism of the process under environmental stresses to reduce stress-related damage and increase the survival rate of the product.

Research on strains used as probiotics is generally predicated on functional properties, but information on their stress tolerance capacity integrated into food matrix and storage is insufficient. Model food systems are required since when a new strain is incorporated into the cheese production process, it must exhibit appropriate survival behavior and control its effects on carbohydrate, protein, and fat utilization [12].

In this study, the following were aimed: (i) to reveal the probiotic potential of autochthonous L. paracasei AD22 by a series of in vitro tests and molecular characterization and (ii) to evaluate its integration into the matrix of brined white cheese in terms of survival and stress response.

Materials and Methods

Isolation and Identification of L. paracasei AD22

In this experimental study, cheese samples (n: 25) were obtained from the villages of Kayseri province between November and December 2021, which were produced from raw milk and stored in plastic barrels for at least six months to mature. The cheese samples (25 g) were kept anaerobically at 37 °C in 225 mL Man, Rogosa, and Sharpe (MRS; Merck, Germany) broth for overnight incubation. Each inoculum (100 μL) was spread on MRS agar and anaerobically incubated at 37 °C for 48 h [13]. Selected colonies were purified and examined according to gram staining and catalase test. The tolerance properties of the selected isolates were examined and the genomic DNAs (gDNA) of isolates were subjected to 16S rRNA sequence analysis. For identification of L. paracasei AD22, gDNA was amplified by Polymerase Chain Reaction (PCR) using universal primers targeting 16S rRNA gene region (27F:5′-AGAGTTTGATCCTGGCTCAG -3′, 1492R: 5′- GGTTACCTTGTTACGACTT -3′) [14]. The amplicons were subjected to Sanger sequencing by Macrogen (South Korea). Paired nucleotide sequences were assembled using the program Geneious Prime 2020.1 (https://www.geneious.com). It was decided to use L. paracasei AD22 for the pilot scale application and characterize it molecularly. Stock cultures of the isolates are kept at – 80 °C in MRS medium with glycerol (20% v/v) in the culture collection of Food Hygiene and Technology Department Laboratuary, Faculty of Veterinary Medicine.

In Vitro Physiological and Safety Traits of L. paracasei AD22

pH tolerance (pH 2, 3 and 7), bile salt tolerance (0.3% and 0.6% bile of bovine origin) and the simulated gastric juice tolerance (%0.3 pepsin at pH 2.5) tests applied by Zheng et al. and the simulated intestinal juice tolerance (adjusting to pH 8.0 with 1 N NaOH by containing 1 mg/L pancreatin, 0.5%NaCl) tests applied by de Oliveira et al. were followed with slight alterations. pH, simulated gastric and intestinal juice tolerance were tested at the 3rd hour of incubation; bile tolerance was analyzed at the 3rd and 24th hour of incubation [15, 16]. Plate counting assessed cell viability and results were expressed as log cfu/mL. NaCI tolerance was evaluated according to Optical Density (OD) indicating turbidity formation measured at 600 nm (OD: 0.10–0.30 indicated slightly turbid, positive poor growth; OD:0.30–0.50 indicated medium turbidity, good growth; OD > 0.60 indicated very turbid, very good improvement; OD < 0.10 indicated negative growth) [17]. Determination of autoaggregation and cell surface hydrophobicity properties was performed via the method described by Yasmin et al. with minor modifications [18]. A coaggregation test was conducted against Staphylococcus aureus ATCC 25923, Salmonella Typhimurium NCTC 74, Escherichia coli ATCC 25922, and Listeria monocytogenes N7144 by adjusting the bacterial suspension of pathogenic bacteria and L. paracasei AD22 at OD600 to 0.5 ± 0.02 [19]. Bacterial adhesion to Caco2 cells was applied according to the method specified by Xu et al. [20]. Antibacterial activity of cell-free supernatant (CFS, 80 μL) from L. paracasei AD22 against Escherichia coli ATCC 25922, Salmonella Typhimurium NCTC74, Listeria monocytogenes N7144, and Staphylococcus aureus ATCC 25923 adjusted to 0.5 MacFarland turbidity was determined by the agar well diffusion method [19]. CFS was obtained by filtering the supernatant after centrifuging an overnight culture inoculated into MRS broths [21]. Antibacterial activity was also determined against selected pathogens using the spot-on lawn method [22]. Antibiotic susceptibility of L. paracasei AD22 to selected antibiotics [vancomycin (VA, 30 μg; Oxoid, UK), trimethoprim and sulfamethoxazole (SXT, 25 μg; Bioanalyse, Türkiye), ampicillin (AMP, 10 mcg; Bioanalyse, Türkiye), cefotaxime (CTX), 30 mcg; Bioanalyse, Türkiye), clindamycin (DA, 2 μg; Bioanalyse, Türkiye), tetracycline (TE, 30 μg; Bioanalyse, Türkiye), streptomycin (S, 10 mcg; Bioanalyse, Türkiye), ciprofloxacin (CIP, 5 μg; Bioanalyse, Türkiye), and erythromycin (E, 15 μg; Oxoid, UK)] were analyzed by disc diffusion method [23]. Inhibition zone diameters of ≤ 14 mm, ≥ 20 mm, and 15–19 mm were considered as resistant (R), sensitive (S), and intermediate (I), respectively [24]. Hemolytic activity was determined using blood agar containing 5% (w/v) sheep blood and plates were incubated at 37 °C for 48 h. Hemolysis status was classified according to the lysis of red blood cells in the medium around the colonies. Green regions around colonies (α-hemolysis), clear regions around colonies (β-hemolysis), and no regions around colonies (γ-hemolysis) indicated hemolysis status. S. aureus ATCC 25923 strain was used as positive control. L. paracasei AD22 was tested for its proteolytic activity on skimmed milk agar medium. A clear or opaque region surrounding the wells indicated positive protease activity [25].

Pilot Scale Cheese Production

Raw milk (10 L) was obtained thrice from Jersey dairy cows in a local farm. Pilot-scale experimental brined white cheeses were grouped as cheese containing L. paracasei AD22 and culture-free control cheese. After pasteurization (72 °C for 20 s), the milk (10 L) was cooled at 42 °C. Calcium chloride solution (0.2% w/v) was added to the cheese milk, followed by L. paracasei AD22. The culture grown overnight on MRS agar was washed three times with 0.5% saline by centrifugation (4000 rpm, 10 min). The suspension (50 mL), adjusted to 1 (5x108 cfu/mL) with 0.5% saline at OD600, was added to 10 L of milk. Rennet (2 mL/100 L) was added to the milk (pH 6.6) when the milk was at 37 °C and coagulation took place in 90 min. Following coagulation, the clot was cut into cubes (3 to 4 cm3) and rested for 10 min. After leaching of the whey (without pressing), pressure was applied at room temperature for eight hours or until the whey drainage stopped. Next, the weights were removed, and the cheese block cut into cubes (3 to 4 cm3) was placed in autoclaved brine (12% NaCl). Precautions were taken to prevent cross-contamination at all stages of cheese making and the glass jars were autoclaved. Cheese groups were ripened for 60 days at 4 °C.

Total Mesophilic Aerobes and Lactobacilli Counting

Microbiological cultivations were carried out at certain intervals (days 0, 1, 3, 7, 15, 30, 45, and 60) during the ripening of the cheeses. To count the total aerobic mesophilic microorganisms on each test day, serial dilutions were prepared with sterile phosphate buffered saline (1:9, pH 7.3) and inoculated onto Plate Count Agar (PCA; Merck, Germany) and incubated at 30 °C for 48–72 h. To count lactobacilli, serial dilutions were inoculated onto MRS agar (Merck, Germany) and incubated at 37 °C for 48–72 h. Analyses were carried out in two parallels. All cell numbers were expressed as logarithms of average colony-forming units per gram of cheese [10].

RNA Extraction, cDNA Synthesis, and Reverse Transcriptase PCR

RNA extraction and determination of RNA concentration (ng/µL), cDNA synthesis and RT-PCR reaction were implemented according to the manufacturer's instructions for the kits mentioned hereinafter. RNA extraction from cheese was performed with the TransZol Up RNA extraction kit (TransGen Biotech, China). The amount of RNA was determined with the Qubit RNA HS Assay Kit (Thermo Fisher Scientific, USA). cDNA was synthesized from two separate RNA extractions concentration adjusted to 30 ng/µL. A high-capacity cDNA Reverse Transcription Kit (Thermo Fisher Scientific, USA) was used for cDNA synthesis. For each reaction, adjusted concentration of 10 μL RNA was added to the mixture containing 10X RT Buffer (2.0 μL), 25X dNTP Mix (100 mM, 0.8 μL), 10X RT Random Primers (2.0 μL), MultiScribeTM Reverse Transcriptase (1 μL), Nuclease-free H2O (4.2 μL). Reverse Transcriptase PCR reaction mixture containing 3.5 µL iQ™ SYBR® Green Supermix (BioRad, USA), 0.5 µL cDNA template, 0.5 µL forward primer (10 µM), 0.5 µL reverse primer (10 µM), and 5 µL sterile water the mixture with a volume of 10 µL was prepared. Each analysis was run with a DNA-free control. Livak and Schmittgen’s 2−ΔΔCT calculation method was used to determine stress-related gene expression level changes [26]. Primer sequences are given in Table 1.

Whole-Genome Sequencing

DNA Extraction and Fragment Analysis

Genomic DNA (gDNA) of Lacticaseibacillus paracasei AD22 was extracted using the Pure Link Genomic DNA Mini Kit (Invitrogen, USA) according to the manufacturer’s instructions. The concentrations of gDNA from the samples and the level of integrity and purity were checked using the Agilent 5400 Fragment Analyzer system. The obtained gDNA was subjected to DNA library preparation using Nextera XT DNA Library Preparation Kit (Illumina, USA) before being transferred to the next-generation sequencing platform. The components other than the fragments to be sequenced in the library were removed following the AMPure XP Bead (Beckman Coulter, UK) kit manufacturer’s instructions. The sequencing process was performed using the NovaSeq 6000 platform (Illumina, USA) with 2 × 150 bp double-ended (PE) chemistry. At the end of the sequencing process, the whole-genome data of the samples were obtained in the “fastq.gz” format.

Bioinformatic Analysis

The Trim Galore open-access program was used to trim adapters and barcodes in the raw readings obtained [27]. In the trimming stage, the -q 10 argument was set to have a base quality score of 10. De novo assembly analyses trimmed.fastq format reads with SPAdes 3.13.0 [28]. Mapping of the isolate with the reference genome was performed with the ProgressiveMauve open-access program using the Lacticaseibacillus paracasei ATCC 27092 (GenBank accession number: NZ_JAMOIQ000000000.1) record as the reference genome [29]. The RAST algorithm was used in the annotation of the strain [30]. The web-based Proksee program was used for the circular graphic representation of the genome assembly and annotation distribution (https://proksee.ca/). Functional subsystems approach was used for the functional genomic distribution of the strain [31]. The BAGEL4 open-access database was used to reveal the bacteriocin clusters [32]. ResFinder4.1 and VirulenceFinder 2.0 databases were used to detect the presence of antibiotic resistance and virulence genes [33, 34].

Statistical Analysis

The statistical significance of the effects of different concentrations and times on the survival profiles of Lacticaseibacillus paracasei AD22 in tested environments was determined by analysis of variance. The effect of ripening time on total mesophilic aerobe count, lactobacilli count, and pH of cheeses was determined by analysis of variance. Additionally, the statistical significance of the difference in total mesophilic aerobe count, lactobacilli count, and pH change between the control and L. paracasei AD22 inoculated cheese groups was determined by analysis of variance. The effect of ripening time on the expression levels of stress-related genes was also examined by analysis of variance. Post hoc analysis was applied to compare intragroup results in each test (Duncan’s multiple comparison, p < 0.05). All statistical analyses were performed using the SPSS 24.0 statistical program [35].

Results

The sequence obtained from the assembly data belonged to 16S rRNA sequencing analysis of the gDNA of Lacticaseibacillus paracasei AD22 has been deposited in GenBank under accession number OR143727.

In Vitro Characterization

Tolerance Characteristics

Tolerance to pH, bile salt, simulated gastric juice, and simulated intestinal juice are shown in Table 2. The effect of different pH exposures on the survival of L. paracasei AD22 was found to be statistically significant (p < 0.05). The effect of different bile salt concentration on the survival rate of L. paracasei AD22 at 3 h was not significant (p > 0.05), but significant at 24 h (p < 0.05). Absorbance values measured at OD600 nm as a result of exposure to environments containing 4%, 8%, and 12% NaCl are shown in Table 2. While moderate turbidity and good growth were detected after exposure to salt-free medium and 4% NaCl medium, less turbidity and weak growth were observed in 8% and 12% NaCl medium. The effect of different salt concentrations on the viability of L. paracasei AD22 was found to be significant (p < 0.05). However, the effect of salt-free medium and 4% NaCl medium on the survival rate was not statistically different from each other (p > 0.05). The effect of 8% and 12% NaCl environments on the survival rate was also statistically insignificant from each other (p > 0.05).

Cell Surface Hydrophobicity, Autoaggregation, Coaggregation, and Bacterial Adhesion to Caco2 Cells

Cell surface hydrophobicity and autoaggregation values were given in Table 3. The effect of time change on the level of autoaggregation was found to be significant (p < 0.05). Coaggregation potential against Staphylococcus aureus ATCC 25923, Salmonella Typhimirium NCTC 74, Escherichia coli ATCC 25922, and Listeria monocytogenes N7144 was given in Table 3. The coaggregation values obtained against each standard pathogen at the 2nd, 20th, and 24th hours were statistically significant (p < 0.05). When standard pathogens were compared, the coaggregation values obtained at each tested time were statistically different (p < 0.05), except for values against Escherichia coli ATCC 25922 and Listeria monocytogenes N7144 at the 24th hour. The adhesion percentage of L. paracasei AD22 to Caco2 cells is given in Table 3.

Antimicrobial Activity

The inhibition effect of L. paracasei AD22 on E. coli ATCC 25922, S. Typhimurium NCTC 74, S. aureus ATCC 25923, and L. monocytogenes ATCC N7144 were determined as 13.5 ± 0.7 mm, 14.5 ± 0.7 mm, 11 ± 0.3 mm, and 13.5 ± 0.7 mm, respectively. Also, according to the spot-on lawn test, zone formation was observed against each standard pathogen examined.

Antibiotic Susceptibility

The sensitivity of L. paracasei AD22 against antibiotics is indicated in Table 4.

Hemolytic and Proteolytic Activity

As a result of the hemolytic activity test, it was observed that L. paracasei AD22 did not form a zone. On skim milk agar medium, L. paracasei AD22 formed zone indicating the proteolytic activity.

Microbiological Enumeration and pH Change

The total mesophilic aerobe and lactobacilli counts of samples on the 1st, 3rd, 7th, 30th, 45th, and 60th days of the ripening period are given in Table 5. There is a statistically significant difference among the groups in the total aerobic mesophilic microorganisms and the lactobacilli counts (log cfu/g) throughout ripening (p < 0.05). A decrease in total aerobic mesophilic microorganisms was observed in the cheese inoculated with L. paracasei AD22 after the 45th day. The pH values measured on the 1st, 3rd, 7th, 30th, 45th, and 60th days of the ripening period are also given in Table 5. The pH change between the groups was statistically significant (p < 0.05) from the first day.

Expression Profile of Stress-Related Genes

The time-dependent variation of the fold changes is shown in Table 6. During ripening, the time-dependent changes of hsp20, dnaK, groES, ftsH, and argH target genes were not statistically significant (p > 0.05).

Whole-Genome Sequencing

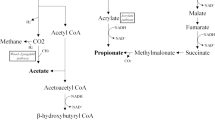

The Lacticaseibacillus paracasei AD22 genome sequencing project has been deposited in GenBank under the accession number JAQPCD000000000. This project’s BioProject and BioSample numbers are PRJNA929671 and SAMN32967350, respectively. De novo assembly read results of L. paracasei AD22 are indicated in Table 7. Figure 1 illustrates a circular graphic representation of the genome annotation distribution of the strain. Subsystem groups and related gene numbers of subsystems according to the functional genomic distribution obtained after whole-genome sequencing and assembly are shown in Fig. 2. Comparative heat maps of heat-cold stress gene and osmotic stress gene presence with reference genomes are given in Fig. 3. ResFinder4.1 database determined that L. paracasei AD22 did not have an antibiotic-resistance gene. VirulenceFinder 2.0 database manifested that L. paracasei AD22 did not carry virulence gene. Four regions of interest for bacteriocin production in the L. paracasei AD22 genome have been determined. Specifically, these genetic clusters encode the production of Enterolysin A (Class III bacteriocin), carnosine CP52 (class II bacteriocin), Enterocin X beta chain (Class IIc bacteriocin), and the LanT region.

Discussion

Evaluation of L. paracasei AD22 in Terms of In Vitro Physiological and Safety Traits

To qualify as a probiotic, the potential candidate must possess certain functional and safety characteristics, including the stomach (low pH, gastric juice, and pepsin) and intestines (pancreatin and bile salts) conditions, adhesion capacity, hemolytic activity, and sensitivity to antibiotics [20, 36]. L. paracasei AD22 showed good probiotic properties, showing remarkable growth in the acidic pH 2 milieu. Kumar et al. and M’hamed et al. reported that no growth occurred due to the incubation of isolated lactobacilli at pH 2 [37, 38]. Adaptation to bile salts is affected by changes in carbohydrate fermentation and glycosidase activity [39], exopolysaccharide production [40], the composition of membrane proteins and fatty acids [41], and human intestinal mucosa and the inhibition of the attachment of pathogens [42]. Like the survival of L. paracasei AD22, Xu et al. stated that L. paracasei L1 strain exhibited 99.8%, 99.2%, and 98.3% tolerance to various levels of exposure to bile salts [20]. Tolerance to pepsin and pancreatic enzymes is also a critical factor in the survival of probiotics after entry into the host [19]. Lu et al. found the survival rate of L. paracasei X11 strain in the simulated gastric and intestinal environment close to the current study [43], while Yilmaz et al. reported the survival rate of L. paracasei KS-199 as 64.1%. L. paracasei AD22 showed tolerance to all NaCl concentrations tested, indicating that the strain withstands the adverse effects of high osmotic pressure in the high salt environment of the gastrointestinal tract and maintains osmotic pressure balance [44].

Adhesion of probiotics is a phenomenon that begins with contact with host enterocytes and continues through various surface interactions [45]. Adhesive strains exhibit an elevated level of hydrophobicity, and the degree of adhesion depends on the surface potential [46]. L. paracasei AD22 is thought to have specific cell surface molecules that play a role in its adhesion ability. While autoaggregation appears to be associated with attachment to epithelial cells [47], coaggregation exhibits antipathogenic traits by forming a defensive barrier against the colonization of pathogenic microorganisms [48]. Coaggregation properties have been found to control a microenvironment around pathogens of probiotic strains and increase the concentration of antimicrobial substances released during aggregation [49]. Similar to the current study, Xu et al. found that the surface hydrophobicity of L. paracasei L1 was 38.1%, and its autoaggregation ability increased significantly with incubation time [20] Xu et al. stated that L. paracasei ATCC 25598 could coaggregate against L. monocytogenes (38.7%) and S. Typhimurium (44.7%) [50]. Amini et al. found the coaggregation level of L. paracasei AS20 to L. monocytogenes to be 56.7% at the end of the 24th hour [51]. Breyer et al. reported the coaggregation percentages of L. paracasei LB 6.4 to E. coli ATCC 25922 and S. aureus ATCC 25923 as 56.3 and 65.5, respectively [52]. According to the findings of our study, L. paracasei AD22 is thought to be beneficial for the competitive elimination of enteropathogens. Caco2 and HT-29 cell lines are the most widely used cell lines for evaluating bacterial strains’ adhesion and anti-adhesion properties [53]. Krausova et al. stated that the adhesion level of L. paracasei E3TA to Caco2 cells was ~ 35% [53]. Unlike L. paracasei strains studied by Xu et al., Xu et al. and Breyer et al., L. paracasei AD22 has a high adhesion ability to Caco2 cell lines [20, 50, 52]. Yasmin et al. stated that cell surface properties still need to be studied in vivo to understand the interaction within the host cell better [18].

L. paracasei AD22 does not show hemolytic activity. Regarding the safety of probiotics, lack of hemolytic activity is essential in selecting probiotic strains, as virulence is not observed among hemolysin-deficient bacterial strains [54]. It has been demonstrated that L. paracasei AD22 exhibits proteolytic activity. The hydrolysis site produced in skimmed milk agar may be related to the amount of protease produced by the organism. Proteolytic enzymes are a group of enzymes that catalyze many different biochemical reactions and can be used in many industries. In particular, in the dairy industry, the proteolytic system of lactic acid bacteria provides essential amino acids to cells during their growth, is involved in the utilization of casein, and plays a remarkable role in regulating the organoleptic properties of fermented milk products [55]. L. paracasei AD22 showed resistance to vancomycin, streptomycin, and ciprofloxacin while showing sensitivity to other antibiotics tested. Anisimova et al. and Liu et al. reported that all lactobacilli tested showed intrinsic resistance to streptomycin, kanamycin, vancomycin, and ciprofloxacin [19, 56]. The resistance of lactobacilli to antibiotics such as aminoglycosides and the absence of electron transfer enzymes mediated by the cytochrome responsible for the metabolism of the antibiotic cannot be taken into the cell, and this is considered as natural resistance [57]. Resistance to vancomycin has been attributed to the presence of D-Ala-D-lactate in its peptidoglycans instead of D-Ala-D-Ala, which is the target of the antibiotic [57]. The European Food Safety Authority (EFSA, 2012) considered the evaluation of vancomycin on L. paracasei as ‘not required’ in the guideline on the antimicrobial susceptibility assessment [58]. Resistance to ciprofloxacin is thought to be due to natural features such as the impermeability of the cell wall or the flow mechanism. Natural resistance to antibiotics is not seen as a threat to the health of animals or humans [59]. One of the crucial mechanisms of probiotics’ action is their antagonistic effect against microbial pathogens with their antimicrobial metabolites. Our study findings comply with Miao et al., Cizeikiene and Jagelaviciute, and Qureshi and Li [60,61,62]. The main compounds responsible for the antimicrobial activity of CFS are lactic and acetic acids, long-chain fatty acids and esters, and proteinaceous compounds [63].

Evaluation of L. paracasei AD22 in Cheese Matrix

It is critical for white-brined cheese to maintain a concentration level of 107 cfu/g for probiotics [64]. It was observed that L. paracasei AD22 achieved this criterion by reaching 7.11 log. Lactobacillus growth was observed on MRS agar plates in the control group. Non-starter LAB can be found in cheese by maintaining its viability from milk pasteurization or post-pasteurization contamination in the dairy [65]. Leeuwendaal et al. reported that the cultures used as adjuncts with probiotic properties continued at 107–108 cfu/g levels in cheese during ripening [66]. Buriti et al. emphasized that the lactobacilli count in Minas cheese produced with commercial starter culture and L. paracasei increased from 6.66 to 8.44 log cfu/g in 21 days and that protocooperation/symbiosis might have occurred between cultures [67]. The differences detected between cheeses in the study were attributed to the initiating microorganism rather than L. paracasei. When the total mesophilic aerobe counts were examined, there were differences from the first day between the control group and the cheese with added L. paracasei AD22. However, the total aerobic mesophilic microorganism count was suppressed in L. paracasei AD22 added cheese after day 45. Similar to the present study, Buriti et al. concluded that the pH value of cheese with probiotics was lower than the control group. Bruti et al. reported that using additional cultures, such as Lactobacillus paracasei, for producing fresh Minas cheese can potentially improve the health properties and quality of the product [67]. However, adding probiotic microorganisms and lactic cultures can solve the problem of weak acidification.

Evaluation of Stress Responses in Cheese Matrix of L. paracasei AD22

In the current study, L. paracasei AD22 was kept at 4 °C during the ripening of brined white cheese and was exposed to a brine environment containing 12% salt and a pH change. Examining the argH, ftsH, hsp20, dnaK, and groES genes was deemed appropriate because the main stress responses result from cold shock, osmotic, and acidity changes. The present study determined the downregulation of genes encoding groES chaperone proteins and hsp20 at refrigerator temperature. The fold changes of these genes during ripening were not statistically significant. However, the stress response of the dnaK shifted to upregulation, which is thought to be due to the cross-protection mechanism during ripening. Liu et al. found that dnaK as a cold stress response is significantly downregulated due to complex translational rearrangements in L. plantarum [68]. Duru evaluated the expression of heat shock response genes such as chaperone genes, Clp protease genes, and the chaperone-binding gene grpE [69]. All these genes have been reported to be downregulated in cold environments in Leuconostoc gelidum, Lactococcus piscium, and Lactobacillus oligofermentans. GroES/GroEL and DnaK/DnaJ have been reported to be induced during environmental conditions such as osmotic and saline stresses, oxidative stress, pH extremes, UV radiation, and the presence of toxic compounds, as well as heat shock stress [70,71,72,73]. Adu et al. emphasized that the Hsp20 family heat shock protein is highly upregulated in response to heat stress compared to other molecular chaperones and that this protein can serve as a valuable biomarker for L. casei GCRL163 in revealing long-term heat stress [74]. ftsH is regulated under the osmotic stress response and heat shock cross-resistance [75]. Expression of ftsH in Oenococcus oeni increased with elevated temperatures and osmotic shock. Bagon et al. emphasized that ftsH is involved in tolerance of L. plantarum WCFS1 and promotes bacterial survival, thus increasing survival under elevated levels of biliary stress [76]. argG and argH are critical genes involved in aspartate and arginine metabolism [77]. Breyer et al. emphasized that overexpression of atpD and argH genes is related to the response to acid and maintaining the presence of LAB in this environment [52]. Huang et al. reported that the expression of argH and argJ in the arginine biosynthesis pathway of Streptococcus thermophilus T1C2 was almost fourfold upregulated compared to control, indicating that S. thermophilus T1C2 began to synthesize arginine to meet growth or survival requirements [78]. In our study, the argH gene for the L. paracasei AD22 showed an upregulation profile over time during cheese ripening. The difference between the fold changes over time was not significant. However, it is thought that L. paracasei AD22, resistant to pH 2.5 in MRS broth, will be a suitable probiotic candidate in cases where the pH drop is high in industrial use.

Whole-Genome Sequencing of L. paracasei AD22

The suitability of the candidate species for use as probiotics is supported by their lack of antibiotic resistance and virulence factors and their ability to produce bacteriocins [79]. No resistance gene was found for L. paracasei AD22. Likewise, Tarrah et al. stated that there are no potential negative features such as antibiotic resistance and virulence factors for L. paracasei DTA93 and reported that it can be evaluated in food products within the scope of health-promoting cultures [80]. The most functional part of the genomic distribution of L. paracasei AD22, showing its potential biological functions, consists of metabolism, protein processing, and stress response functions. Genomic analysis provides in-depth information on the functional mechanisms involved in potential probiotics and their adaptation to the environment. Zheng et al. reported that the immune system process, adhesion, amino acid, and carbohydrate metabolism constitute the majority of the functional genomic features of L. rhamnosus CY12 and stated that the strain has metabolic ability and tolerance [15]. Comparative heat maps with reference genomes identified genes conferring heat and cold shock tolerance, such as heat shock proteins and members of the cold shock protein family. Accordingly, L. paracasei AD22 encodes the DnaK and DnaJ chaperone system that helps protein folding under stress conditions. The protein repair function of DnaK, GrpE, and especially DnaJ is likely to be part of the role of these proteins in regulating the heat shock response [81]. The gene yabA, which encodes DNA replication-initiating protein, has a functional relationship with the replication mechanism [82]. While HSPs are essential for cell development, their catalytic activity becomes particularly important under stress conditions that lead to the accumulation of unfolded or misfolded proteins. These include genes encoding the chaperone protein (DnaK, DnaJ) and the nucleoside 5′-triphoaphate RdgB, essential in adaptations to psychrophilic lifestyles [83]. LepA induces back-translocation of tRNAs on the ribosome [84, 85], which is formed by progressing from the post-translocation complex to the pre-translocation complex [86]. A thorough understanding of the cold-adaptation process can be used to optimize low-temperature fermentations. It can provide insight into methods of controlling the growth of pathogenic bacteria and spoilage, which affect the shelf life and safety of foods stored in the refrigerator [87]. On the other hand, cold shock refers to the reaction of mesophilic or psychrotrophic microorganisms to a sudden and significant drop in temperature. Protein-encoding genes facilitating glycerol uptake are necessary for the intracellular transport of glycerol and metabolism functions in bacteria [88]. When osmotic stress responses were examined, it was concluded that L. paracasei AD22 contains opuBA-opuBB-opuBC-opuBD operons that are involved in the transport of osmoprotectants such as glycine betaine, proline, choline, or carnitine [89]. The expression of opuB operons is regulated in response to the increased osmolality of the growth medium [90]. Kiousi et al. stated that L. paracasei SP5 contains genes necessary to produce glycine betaine binding factors and osmolyte transporters that accumulate in the cell under hypertonic shock [91]. In addition, it has been reported that the synergistic activity of GrpE with DnaK and DnaJ during hyperosmotic shock reduces the damage to the macromolecular mechanism of the cell. The BAGEL4 analysis revealed the existence of Enterolysin A, Carnosine CP52, Enterocin X beta chain interested in bacteriocin production in the L. paracasei AD22 genome. In addition, the lantibiotic transporter LanT region identified in its genome can be evidence of the possible existence of new clusters for lantibiotic production [92].

In conclusion, L. paracasei AD22 can be used in developing new functional products and producing fermented foods since it has the structural features that a probiotic culture should have. Considering L. paracasei AD22 more comprehensively within the framework of omics approaches will enable it to be evaluated in terms of revealing the characteristics and capabilities of the strain, obtaining scientific data regarding health-promoting studies.

Data Availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdel Tawab FI, Abd Elkadr MH, Sultan AM, Hamed EO, El-Zayat AS, Ahmed MN (2023) Probiotic potentials of lactic acid bacteria isolated from Egyptian fermented food. Sci Rep 13(1):16601. https://doi.org/10.1038/s41598-023-43752-0

Soleimani H, Shokri R, Nami Y, Khandaghi J, Panahi B (2023) Potential probiotic characterization of lactic acid bacteria isolated from Duimaj, an Iranian traditional snack food, using biochemical, molecular, and computational approaches. LWT-Food Sci Technol 184:115091. https://doi.org/10.1016/j.lwt.2023.115091

Saxami G, Karapetsas A, Lamprianidou E, Kotsianidis I, Chlichlia A, Tassou C, Galanis A (2016) Two potential probiotic lactobacillus strains isolated from olive microbiota exhibit adhesion and anti-proliferative effects in cancer cell lines. J Funct Foods 24:461–471. https://doi.org/10.1016/j.jff.2016.04.036

Gangoiti MV, Puertas AI, Hamet MF, Peruzzo PJ, Llamas MG, Medrano M, Abraham AG (2017) Lactobacillus plantarum CIDCA 8327: an α-glucan producing-strain isolated from kefir grains. Carbohydr Polym 170:52–59. https://doi.org/10.1016/j.carbpol.2017.04.053

Plessas S, Nouska C, Karapetsas A, Kazakos S, Alexopoulos A, Mantzourani I, Bezirtzoglou E (2017) Isolation, characterization, and evaluation of the probiotic potential of a novel Lactobacillus strain isolated from Feta-type cheese. Food Chem 226:102–108. https://doi.org/10.1016/j.foodchem.2017.01.052

Hernández-Alcántara AM, Wacher C, Llamas MG, López P, Pérez-Chabela ML (2018) Probiotic properties and stress response of thermotolerant lactic acid bacteria isolated from cooked meat products. LWT-Food Sci Technol 91:249–257. https://doi.org/10.1016/j.lwt.2017.12.063

Novak J, Butorac K, Leboš Pavunc A, Banić M, Butorac A, Lepur A, Kos B (2021) A lactic acid bacteria consortium impacted the content of casein-derived biopeptides in dried fresh cheese. Molecules 27(1):160. https://doi.org/10.3390/molecules27010160

Damián MR, Cortes-Perez NG, Quintana ET, Ortiz-Moreno A, Garfias Noguez C, Cruceño-Casarrubias CE, Bermúdez-Humarán LG (2022) Functional foods, nutraceuticals and probiotics: a focus on human health. Microorganisms 10(5):1065. https://doi.org/10.3390/microorganisms10051065

Terpou A, Gialleli AI, Bosnea L, Kanellaki M, Koutinas AA, Castro GR (2017) Novel cheese production by incorporation of sea buckthorn berries (Hippophae rhamnoides L) supported probiotic cells. LWT-Food Sci Technol 79:616–624. https://doi.org/10.1016/j.lwt.2016.11.021

Terpou A, Mantzourani I, Galanis A, Kanellaki M, Bezirtzoglou E, Bekatorou A, Plessas S (2018) Employment of L paracasei K5 as a novel potentially probiotic freeze-dried starter for Feta-type cheese production. Microorganisms 7(1):3. https://doi.org/10.3390/microorganisms7010003

Castro JM, Tornadijo ME, Fresno JM, Sandoval H (2015) Biocheese: a food probiotic carrier. Biomed Res Int 2015:723056. https://doi.org/10.1155/2015/723056

Aguirre-Ezkauriatza EJ, Aguilar-Yáñez JM, Ramírez-Medrano A, Alvarez MM (2010) Production of probiotic biomass (Lactobacillus casei) in goat milk whey: comparison of batch continuous and fed-batch cultures. Bioresour Technol 101(8):2837–2844. https://doi.org/10.1016/j.biortech.2009.10.047

Mulaw G, Sisay Tessema T, Muleta D, Tesfaye A (2019) In vitro evaluation of probiotic properties of lactic acid bacteria isolated from some traditionally fermented Ethiopian food products. Int J Microbiol 2019:7179514. https://doi.org/10.1155/2019/7179514

Suzuki M, Giovannoni SJ (1996) Bias caused by template annealing in the amplification of mixtures of 16S rRNA genes by PCR. Appl Environ Microbiol 62(2):625–630. https://doi.org/10.1128/aem.62.2.625-630.1996

Zheng J, Du M, Jiang W, Zhan J, Shen W, Ma X, Ding X (2021) In vitro probiotic characteristics and whole genome sequence analysis of lactobacillus strains isolated from cattle-yak milk. Biology 11(1):44. https://doi.org/10.3390/biology11010044

de Oliveira CB, Fiorda-Mello F, de Melo Pereira GV, Thomaz-Soccol V, Rakshi SK, de Carvalho JC, Soccol CR (2019) In vitro probiotic properties and DNA protection activity of yeast and lactic acid bacteria isolated from a honey-based kefir beverage. Foods 8(10):485. https://doi.org/10.3390/foods8100485

Bozdemir M (2021) Bozadan izole edilmiş laktik asit bakterilerinin bazı teknolojik ve fonksiyonel özellikleri. University of Tekirdağ Namık Kemal (Master Thesis)

Yasmin I, Saeed M, Khan WA, Khaliq A, Chughtai MFJ, Iqbal R, Tanweer S (2020) In vitro probiotic potential and safety evaluation (hemolytic, cytotoxic activity) of Bifidobacterium strains isolated from raw camel milk. Microorganisms 8(3):354. https://doi.org/10.3390/microorganisms8030354

Liu C, Xue WJ, Ding H, An C, Ma SJ, Liu Y (2022) Probiotic potential of Lactobacillus strains isolated from fermented vegetables in shaanxi. China. Front Microbiol 12:774903. https://doi.org/10.3389/fmicb.2021.774903

Xu Y, Tian Y, Cao Y, Li J, Guo H, Su Y, Zhang L (2019) Probiotic properties of Lactobacillus paracasei subsp paracasei L1 and its growth performance-promotion in chicken by improving the intestinal microflora. Front Physiol 10:937. https://doi.org/10.3389/fphys.2019.00937

Kaewchomphunuch T, Charoenpichitnunt T, Thongbaiyai V, Ngamwongsati N, Kaeoket K (2022) Cell-free culture supernatants of Lactobacillus spp and Pediococcus spp inhibit growth of pathogenic Escherichia coli isolated from pigs in Thailand. BMC Vet Res 18(1):1–13. https://doi.org/10.1186/s12917-022-03140-8

Akbar A, Sadiq MB, Ali I, Anwar M, Muhammad N, Muhammad J, Anal AK (2019) Lactococcus lactis subsp lactis isolated from fermented milk products and its antimicrobial potential CyTA-J Food 17(1):214–220. https://doi.org/10.1080/19476337.2019.1575474

Hudzicki J (2009) Kirby-Bauer disk diffusion susceptibility test protocol. ASM 15:55–63

Singla V, Mandal S, Sharma P, Anand S, Tomar SK (2018) Antibiotic susceptibility profile of Pediococcus spp. from diverse sources. 3 Biotech 8(12):489. https://doi.org/10.1007/s13205-018-1514-6

Raveschot C, Cudennec B, Deracinois B, Frémont M, Vaeremans M, Dugersuren J, Flahaut C (2020) Proteolytic activity of Lactobacillus strains isolated from Mongolian traditional dairy products: a multiparametric analysis. Food Chem 304:125415. https://doi.org/10.1016/j.foodchem.2019.125415

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2- ΔΔCT method. Methods 25(4):402–408. https://doi.org/10.1006/meth.2001.1262

Krueger F (2012) Trim Galore: a wrapper tool around Cutadapt and FastQC to consistently apply quality and adapter trimming to FastQ files, with some extra functionality for MspI-digested RRBS-type (reduced representation Bisufite-Seq) libraries. http://www.bioinformatics.babraham.ac.uk/projects/trim_galore/. Accessed 15 July 2022

Bankevich A, Nurk S, Antipov D, Gurevich AA, Dvorkin M, Kulikov AS, Pevzner PA (2012) SPAdes: a new genome assembly algorithm and its applications to single-cell sequencing. J Comput Biol 19(5):455–477. https://doi.org/10.1089/cmb.2012.0021

Darling AE, Mau B, Perna NT (2010) ProgressiveMauve: multiple genome alignment with gene gain, loss and rearrangement. PloS One 5(6):e11147. https://doi.org/10.1371/journal.pone.0011147

Brettin T, Davis JJ, Disz T, Edwards RA, Gerdes S, Olsen GJ, Xia F (2015) RASTtk: a modular and extensible implementation of the RAST algorithm for building custom annotation pipelines and annotating batches of genomes. Sci Rep 5(1):8365. https://doi.org/10.1038/srep08365

Overbeek R, Begley T, Butler RM, Choudhuri JV, Chuang HY, Cohoon M, Vonstein V (2005) The subsystems approach to genome annotation and its use in the project to annotate 1000 genomes. Nucleic Acids Res 33(17):5691–5702. https://doi.org/10.1093/nar/gki866

van Heel AJ, de Jong A, Song C, Viel JH, Kok J, Kuipers OP (2018) BAGEL4: a user-friendly web server to thoroughly mine RiPPs and bacteriocins. Nucleic Acids Res 46(W1):W278–W281. https://doi.org/10.1093/nar/gky383

Joensen KG, Scheutz F, Lund O, Hasman H, Kaas RS, Nielsen EM, Aarestrup FM (2014) Real-time whole-genome sequencing for routine typing, surveillance, and outbreak detection of verotoxigenic Escherichia coli. J Clin Microbiol 52(5):1501–1510. https://doi.org/10.1128/JCM.03617-13

Bortolaia V, Kaas RS, Ruppe E, Roberts MC, Schwarz S, Cattoir V, Aarestrup FM (2020) ResFinder 40 for predictions of phenotypes from genotypes. J Antimicrob Chemother 75(12):3491–3500. https://doi.org/10.1093/jac/dkaa345

Duzgunes O, Kesici T, Gurbuz F (1983) İstatistik Metodlari. Ankara Universitesi Ziraat Fakultesi Yayinlari, Ankara

de Melo Pereira GV, de Oliveira Coelho B, Júnior AIM, Thomaz-Soccol V, Soccol CR (2018) How to select a probiotic? A review and update of methods and criteria. Biotechnol Adv 36(8):2060–2076. https://doi.org/10.1016/j.biotechadv.2018.09.003

Kumar A, Kumar D (2015) Characterization of Lactobacillus isolated from dairy samples for probiotic properties. Anaerobe 33:117–123. https://doi.org/10.1016/j.anaerobe.2015.03.004

M’hamed ac, Ncib k, Merghni A, Migaou M, Lazreg H, Snoussi M, Maaroufi RM (2022) Characterization of probiotic properties of Lacticaseibacillus paracasei L2 isolated from a traditional fermented food “Lben.” Life 13(1):21. https://doi.org/10.3390/life13010021

Taheri HR, Moravej H, Tabandeh F, Zaghari M, Shivazad M (2009) Screening of lactic acid bacteria toward their selection as a source of chicken probiotic. Poult Sci 88(8):1586–1593. https://doi.org/10.3382/ps.2009-00041

Shazali N, Foo HL, Loh TC, Choe DW, Abdul Rahim R (2014) Prevalence of antibiotic resistance in lactic acid bacteria isolated from the faeces of broiler chicken in Malaysia. Gut pathogens 6(1):1–7. https://doi.org/10.1186/1757-4749-6-1

Fairbrother JM, Nadeau É, Gyles CL (2005) Escherichia coli in postweaning diarrhea in pigs: an update on bacterial types, pathogenesis, and prevention strategies. Anim Health Res Rev 6(1):17–39. https://doi.org/10.1079/ahr2005105

Venkatesan S, Kirithika M, Roselin I, Ganesan R, Muthuchelian K (2012) Comparative invitro and invivo study of three probiotic organisms, Bifidobacterium sp, Lactobacillus sp, S cerevisiae and analyzing its improvement with the supplementation of prebiotics. Ichnos 2:94–106

Lu Y, Zhang J, Zhou X, Guan M, Zhang Z, Liang X, Zhang L (2021) The edible Lactobacillus paracasei X11 with Konjac glucomannan promotes intestinal motility in zebrafish. Neurogastroenterol Motil 33(12):e14196. https://doi.org/10.1111/nmo.14196

Yilmaz MT, Taylan O, Karakas CY, Dertli E (2020) An alternative way to encapsulate probiotics within electrospun alginate nanofibers as monitored under simulated gastrointestinal conditions and in kefir. Carbohydr Polym 244:116447. https://doi.org/10.1016/j.carbpol.2020.116447

Reuben RC, Roy PC, Sarkar SL, Alam ARU, Jahid IK (2020) Characterization and evaluation of lactic acid bacteria from indigenous raw milk for potential probiotic properties. J Dairy Sci 103(2):1223–1237. https://doi.org/10.3168/jds.2019-17092

Ayyash M, Abushelaibi A, Al-Mahadin S, Enan M, El-Tarabily K, Shah N (2018) In-vitro investigation into probiotic characterisation of Streptococcus and Enterococcus isolated from camel milk. LWT - Food Sci Technol 87:478–487. https://doi.org/10.1016/j.lwt.2017.09.019

Collado MC, Meriluoto J, Salminen S (2008) Adhesion and aggregation properties of probiotic and pathogen strains. Eur Food Res Technol 226:1065–1073. https://doi.org/10.1007/s00217-007-0632-x

Abushelaibi A, Al-Mahadin S, El-Tarabily K, Shah NP, Ayyash M (2017) Characterization of potential probiotic lactic acid bacteria isolated from camel milk. LWT - Food Sci Technol 79:316–325. https://doi.org/10.1016/j.lwt.2017.01.041

Merino L, Trejo FM, De Antoni G, Golowczyc MA (2019) Lactobacillus strains inhibit biofilm formation of Salmonella sp isolates from poultry. Food Res Int 123:258–265. https://doi.org/10.1016/j.foodres.2019.04.067

Xu H, Jeong HS, Lee HY, Ahn J (2009) Assessment of cell surface properties and adhesion potential of selected probiotic strains. Lett Appl Microbiol 49(4):434–442. https://doi.org/10.1111/j.1472-765X.2009.02684.x

Amini E, Salimi F, Imanparast S, Mansour FN (2022) Isolation and characterization of exopolysaccharide derived from Lacticaseibacillus paracasei AS20 (1) with probiotic potential and evaluation of its antibacterial activity. Lett Appl Microbiol 75(4):967–981. https://doi.org/10.1111/lam.13771

Breyer GM, Arechavaleta NN, Siqueira FM, de Souza da Motta A (2021) Characterization of lactic acid bacteria in raw buffalo milk: a screening for novel probiotic candidates and their transcriptional response to acid stress. Probiotics Antimicrob 13:468–483. https://doi.org/10.1007/s12602-020-09700-4

Krausova G, Hyrslova I, Hynstova I (2019) In vitro evaluation of adhesion capacity, hydrophobicity, and auto-aggregation of newly isolated potential probiotic strains. Fermentation 5(4):100. https://doi.org/10.3390/fermentation5040100

FAO/WHO (2002) Joint FAO/WHO working group report on drafting guidelines for the evaluation of probiotics in food London, Ontario, Canada, 30 April-1 May. https://www.fao.org/3/a0512e/a0512e.pdf. Accessed 15 July 2022

Kieliszek M, Pobiega K, Piwowarek K, Kot AM (2021) Characteristics of the proteolytic enzymes produced by lactic acid bacteria. Molecules 26(7):1858. https://doi.org/10.3390/molecules26071858

Anisimova E, Gorokhova I, Karimullina G, Yarullina D (2022) Alarming antibiotic resistance of lactobacilli isolated from probiotic preparations and dietary supplements. Antibiotics 11(11):1557. https://doi.org/10.3390/antibiotics11111557

Monteagudo-Mera A, Rodríguez-Aparicio L, Rúa J, Martínez-Blanco H, Navasa N, García-Armesto MR, Ferrero MÁ (2012) In vitro evaluation of physiological probiotic properties of different lactic acid bacteria strains of dairy and human origin. J Func Foods 4(2):531–541. https://doi.org/10.1016/j.jff.2012.02.014

Aquilina G, Bories G, Chesson A, Cocconcelli PS, de Knecht J, Dierick NA, Gralak MA, Gropp J, Halle I, Hogstrand C, Leng L, Puente SL, Haldorsen AKL, Mantovani A, Martelli G, Mézes M, Renshaw D, Saarela M, Sejrsen K, Westendorf J (2012) Panel on Additives and Products or Substances used in Animal Feed (FEEDAP). Guidance on the assessment of bacterial susceptibility to antimicrobials of human and veterinary importance. EFSA J 10(6):2740. https://doi.org/10.2903/j.efsa.2012.2740

Al Kassaa I, Hamze M, Hober D, Chihib NE, Drider D (2014) Identification of vaginal lactobacilli with potential probiotic properties isolated from women in North Lebanon. Microb Ecol 67:722–734. https://doi.org/10.1007/s00248-014-0384-7

Miao J, Guo H, Ou Y, Liu G, Fang X, Liao Z, Cao Y (2014) Purification and characterization of bacteriocin F1, a novel bacteriocin produced by Lactobacillus paracasei subsp tolerans FX-6 from Tibetan kefir, a traditional fermented milk from Tibet, China. Food Control 42:48–53. https://doi.org/10.1016/j.foodcont.2014.01.041

Cizeikiene D, Jagelaviciute J (2021) Investigation of antibacterial activity and probiotic properties of strains belonging to Lactobacillus and Bifidobacterium genera for their potential application in functional food and feed products. Probiotics Antimicrob 1–17. https://doi.org/10.1007/s12602-021-09777-5

Qureshi N, Gu Q, Li P (2020) Whole genome sequence analysis and in vitro probiotic characteristics of a Lactobacillus strain Lactobacillus paracasei ZFM54. J Appl Microbiol 129(2):422–433. https://doi.org/10.1111/jam.14627

Mani-López E, Arrioja-Bretón D, López-Malo A (2022) The impacts of antimicrobial and antifungal activity of cell-free supernatants from lactic acid bacteria in vitro and foods. Compr Rev Food Sci Food Saf 21(1):604–641. https://doi.org/10.1111/1541-4337.12872

Dabevska-Kostoska M, Velickova E, Kuzmanova S, Winkelhausen E (2015) Traditional white brined cheese as a delivery vehicle for probiotic bacterium Lactobacillus casei. Maced J Chem Chem Eng 34(2):343–350. https://doi.org/10.20450/mjcce.2015.519

Østlie HM, Kraggerud H, Longva AB, Abrahamsen RK (2016) Characterisation of the microflora during ripening of a Norwegian semi-hard cheese with adjunct culture of propionic acid bacteria. Int Dairy J 54:43–49. https://doi.org/10.1016/j.idairyj.2015.10.005

Leeuwendaal NK, Hayes JJ, Stanton C, O’Toole PW, Beresford TP (2022) Protection of candidate probiotic lactobacilli by Cheddar cheese matrix during simulated gastrointestinal digestion. J Func Foods 92:105042. https://doi.org/10.1016/j.jff.2022.105042

Buriti FC, da Rocha JS, Assis EG, Saad SM (2005) Probiotic potential of Minas fresh cheese prepared with the addition of Lactobacillus paracasei. LWT-Food Sci Technol 38(2):173–180. https://doi.org/10.1016/j.lwt.2004.05.012

Liu S, Ma Y, Zheng Y, Zhao W, Zhao X, Luo T, Yang Z (2020) Cold-stress response of probiotic Lactobacillus plantarum K25 by iTRAQ proteomic analysis. J Microbiol Biotechnol 30(2):187. https://doi.org/10.4014/jmb.1909.09021

Duru IC (2021) Transcriptomic analysis of food-related microorganisms: cheese microbiota, food spoilage lactic acid bacteria, and foodborne pathogens. University of Helsinki (Doctorate Thesis)

Farr SB, Kogoma T (1991) Oxidative stress responses in Escherichia coli and Salmonella typhimurium. Microbiol Rev 55(4):561–585. https://doi.org/10.1128/mr.55.4.561-585.1991

Hanawa T, Yamamoto T, Kamiya S (1995) Listeria monocytogenes can grow in macrophages without the aid of proteins induced by environmental stresses. Infect Immun 63(12):4595–4599. https://doi.org/10.1128/iai.63.12.4595-4599.1995

Teixeira-Gomes AP, Cloeckaert A, Zygmunt MS (2000) Characterization of heat, oxidative, and acid stress responses in Brucella melitensis. Infect Immun 68(5):2954–2961. https://doi.org/10.1128/IAI.68.5.2954-2961.2000

Prasad J, McJarrow P, Gopal P (2003) Heat and osmotic stress responses of probiotic Lactobacillus rhamnosus HN001 (DR20) in relation to viability after drying. Appl Environ Microbiol 69(2):917–925. https://doi.org/10.1128/AEM.69.2.917-925.2003

Adu KT, Wilson R, Nichols DS, Baker AL, Bowman JP, Britz ML (2018) Proteomic analysis of Lactobacillus casei GCRL163 cell-free extracts reveals a SecB homolog and other biomarkers of prolonged heat stress. PLoS One 13(10):e0206317. https://doi.org/10.1371/journal.pone.0206317

Kolendo J, Sokołowska B (2017) Lactic acid bacteria stress response to preservation processes in the beverage and juice industry. Acta Biochim Pol 64(3):459–464. https://doi.org/10.18388/abp.2017_1496

Bagon BB, Oh JK, Valeriano VDV, Pajarillo AB, Kang DK (2021) Exploring the bile stress response of Lactobacillus mucosae LM1 through exoproteome analysis. Molecules 26(18):5695. https://doi.org/10.3390/molecules26185695

Zhang W, Yu D, Sun Z, Wu R, Chen X, Chen W, Zhang H (2010) Complete genome sequence of Lactobacillus casei Zhang, a new probiotic strain isolated from traditional homemade koumiss in Inner Mongolia. China. J Bacteriol 192(19):5268–5269. https://doi.org/10.1128/JB.00802-10

Huang S, Ai ZW, Sun XM, Liu GF, Zhai S, Zhang M, Feng Z (2016) Influence of arginine on the growth, arginine metabolism and amino acid consumption profiles of Streptococcus thermophilus T1C2 in controlled pH batch fermentations. J Appl Microbiol 121(3):746–756. https://doi.org/10.1111/jam.13221

Torres-Miranda A, Melis-Arcos F, Garrido D (2022) Characterization and identification of probiotic features in Lacticaseibacillus Paracasei using a comparative genomic analysis approach. Probiotics Antimicrob 14(6):1211–1224. https://doi.org/10.1007/s12602-022-09999-1

Tarrah A, Pakroo S, Corich V, Giacomini A (2020) Whole-genome sequence and comparative genome analysis of Lactobacillus paracasei DTA93, a promising probiotic lactic acid bacterium. Arch Microbiol 202:1997–2003. https://doi.org/10.1007/s00203-020-01883-2

Schröder H, Langer T, Hartl FU, Bukau B (1993) DnaK, DnaJ and GrpE form a cellular chaperone machinery capable of repairing heat-induced protein damage. EMBO J 12(11):4137–4144. https://doi.org/10.1002/j.1460-2075.1993.tb06097.x

Noirot-Gros MF, Velten M, Yoshimura M, McGovern S, Morimoto T, Ehrlich SD, Noirot P (2006) Functional dissection of YabA, a negative regulator of DNA replication initiation in Bacillus subtilis. PNAS 103(7):2368–2373. https://doi.org/10.1073/pnas.0506914103

Reddy B, Singh KM, Patel AK, Antony A, Panchasara HJ, Joshi CG (2014) Insights into resistome and stress responses genes in Bubalus bubalis rumen through metagenomic analysis. Mol Biol Rep 41:6405–6417. https://doi.org/10.1007/s11033-014-3521-y

Qin Y, Polacek N, Vesper O, Staub E, Einfeldt E, Wilson DN, Nierhaus KH (2006) The highly conserved LepA is a ribosomal elongation factor that back-translocates the ribosome. Cell 127(4):721–733. https://doi.org/10.1016/j.cell.2006.09.037

Evans RN, Blaha G, Bailey S, Steitz TA (2008) The structure of LepA, the ribosomal back translocase. PNAS 105(12):4673–4678. https://doi.org/10.1073/pnas.0801308105

Liu H, Pan D, Pech M, Cooperman BS (2010) Interrupted catalysis: the EF4 (LepA) effect on back-translocation. J Mol Biol 396(4):1043–1052. https://doi.org/10.1016/j.jmb.2009.12.043

Wouters JA, Rombouts FM, Kuipers OP, De Vos WM, Abee T (2000) The role of cold-shock proteins in low-temperature adaptation of food-related bacteria. Syst Appl Microbiol 23(2):165–173. https://doi.org/10.1016/S0723-2020(00)80001-6

Smythe P, Efthimiou G (2022) In silico genomic and metabolic atlas of Limosilactobacillus reuteri DSM 20016: an insight into human health. Microorganisms 10(7):1341. https://doi.org/10.3390/microorganisms10071341

Maughan H, Nicholson WL (2011) Increased fitness and alteration of metabolic pathways during Bacillus subtilis evolution in the laboratory. Appl Environ Microbiol 77(12):4105–4118. https://doi.org/10.1128/AEM.00374-11

Kappes RM, Kempf B, Kneip S, Boch J, Gade J, Meier-Wagner J, Bremer E (1999) Two evolutionarily closely related ABC transporters mediate the uptake of choline for synthesis of the osmoprotectant glycine betaine in Bacillus subtilis. Mol Microbiol 32(1):203–216. https://doi.org/10.1046/j.1365-2958.1999.01354.x

Kiousi DE, Efstathiou C, Tegopoulos K, Mantzourani I, Alexopoulos A, Plessas S, Galanis A (2022) Genomic insight into lacticaseibacillus paracasei SP5, reveals genes and gene clusters of probiotic interest and biotechnological potential. Front Microbiol 13:922689. https://doi.org/10.3389/fmicb.2022.922689

Singh M, Sareen D (2014) Novel LanT associated lantibiotic clusters identified by genome database mining. PLoS One 9(3):e91352. https://doi.org/10.1371/journal.pone.0091352

Acknowledgements

We want to thank Erciyes University Scientific Text Support Office (Proofreading & Editing Office) for their contributions in checking and editing the English language of the manuscript.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This study was summarized from the Ph.D. thesis and supported by the Scientific Research Projects Coordinator of Erciyes University, Türkiye (TDK-2021–11389).

Author information

Authors and Affiliations

Contributions

Conceptualization, Data curation, Formal Analysis, Statistics: AD, ZG; Investigation, Methodology, Writing – Original draft: AD; Project administration, Supervision, Writing – Review & editing: AD, ZG.

Corresponding author

Ethics declarations

Ethical Approval

No ethical approval was required as no live animals were used in this study.

Competing Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

DISHAN, A., GÖNÜLALAN, Z. Lacticaseibacillus paracasei AD22 Stress Response in Brined White Cheese Matrix: In Vitro Probiotic Profiles and Molecular Characterization. Probiotics & Antimicro. Prot. (2024). https://doi.org/10.1007/s12602-024-10216-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s12602-024-10216-4