Abstract

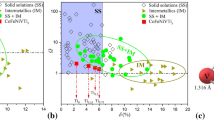

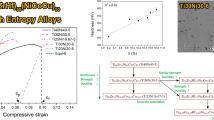

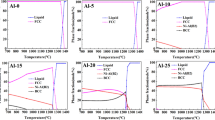

(CrFeNiCu)100–xTix (x = 0, 3, 5, 7 and 10; at%) high-entropy alloys have been designed by the consideration of the thermophysical relationship between Ti and other principal elements to investigate the influence of Ti on the microstructural evolution and mechanical properties of (CrFeNiCu)100–xTix high-entropy alloys. The addition of Ti content in HEAs leads to a change in phase formation from dual-phase (FCC1 and FCC2, FCC: face-centered cubic) to the mixture of FCC1, FCC2 phases, and an additional body-centered cubic (BCC) phase. The yield strength and Vickers hardness of the alloys are enhanced from 291 to 1511 MPa and HV 134 to HV 531, respectively, which depends strongly on the volume fraction of BCC phase. On the one hand, the plasticity of the alloys reduces from 45.00% to 24.09%, but it could be considered reasonable plasticity. These results revealed that the addition of a minor alloying element in high-entropy alloys with consideration of thermophysical parameters led to the formation of a multiple solid solution structure with excellent mechanical properties.

Graphical Abstract

Similar content being viewed by others

References

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299. https://doi.org/10.1002/adem.200300567.

Lu ZP, Wang H, Chen MW, Baker I, Yeh JW, Liu CT, Nieh TG. An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics. 2015;66:67. https://doi.org/10.1016/j.intermet.2015.06.021.

Tsai MH, Yeh JW. High-entropy alloys: a critical review. Mater Res Lett. 2014;2(3):107. https://doi.org/10.1080/21663831.2014.912690.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448. https://doi.org/10.1016/j.actamat.2016.08.081.

Yeh JW. Recent progress in high-entropy alloys. Ann Chim Sci Des Mater. 2016;31(6):633. https://doi.org/10.3166/acsm.31.633-648.

Guo S, Liu CT. Phase stability in high entropy alloys: formation of solid-solution phase or amorphous phase. Prog Nat Sci Mater Int. 2011;21(6):433. https://doi.org/10.1016/S1002-0071(12)60080-X.

Huang PK, Yeh JW, Shun TT, Chen SK. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv Eng Mater. 2004;6(1–2):74. https://doi.org/10.1002/adem.200300507.

Li Z, Pradeep KG, Deng Y, Rabbe D, Tasan CC. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature. 2016;534:227. https://doi.org/10.1038/nature17981.

Yang T, Zhao YL, Tong Y, Jiao ZB, Wei J, Cai JX, Han XD, Chen D, Hu A, Kai JJ, Lu K, Liu Y, Liu CT. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science. 2018;362(6417):933. https://doi.org/10.1126/science.aas8815.

Hou J, Zhang M, Yang H, Qiao J, Wu Y. Surface strengthening in Al0.25CoCrFeNi high-entropy alloy by boronizing. Mater Lett. 2019;238:258. https://doi.org/10.1016/j.matlet.2018.12.029.

Fan JT, Zhang LJ, Yu PF, Zhang MF, Liu DJ, Zhou Z, Cui P, Ma MZ, Jing Q, Li G, Liu RP. Improved the microstructure and mechanical properties of AlFeCoNi high-entropy alloy by carbon addition. Mater Sci Eng A. 2018;728:30. https://doi.org/10.1016/j.msea.2018.05.013.

Senkov ON, Senkova SV, Dimiduk DM, Woodward C, Miracle DB. Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J Mater Sci. 2012;47:6522. https://doi.org/10.1007/s10853-012-6582-0.

Huang YS, Chen L, Lui HW, Cai MH, Yeh JW. Microstructure, hardness, resistivity and thermal stability of sputtered oxide films of AlCoCrCu0.5 NiFe high-entropy alloy. Mater Sci Eng A. 2007;457:77. https://doi.org/10.1016/j.msea.2006.12.001.

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans. 2005;46(12):2817. https://doi.org/10.2320/matertrans.46.2817.

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP. Microstructures and properties of high-entropy alloys. Prog Mater Sci. 2014;61:1. https://doi.org/10.1016/j.pmatsci.2013.10.001.

Yang X, Zhang Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater Chem Phys. 2012;132(2–3):233. https://doi.org/10.1016/j.matchemphys.2011.11.021.

Guo S, Ng C, Lu J, Liu CT. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J Appl Phys. 2011;109(10):103505. https://doi.org/10.1063/1.3587228.

Ng C, Guo S, Luan J, Shi S, Liu CT. Entropy-driven phase stability and slow diffusion kinetics in an Al0.5CoCrCuFeNi high entropy alloy. Intermetallics. 2012;31:165. https://doi.org/10.1016/j.intermet.2012.07.001.

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh YG, Lu ZP. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014;62:105. https://doi.org/10.1016/j.actamat.2013.09.037.

Liu WH, Lu ZP, He JY, Luan JH, Wang ZJ, Liu B, Liu Y, Chen MW, Liu CT. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016;116:332. https://doi.org/10.1016/j.actamat.2016.06.063.

Stepanov ND, Shaysultanov DG, Salishchev GA, Tikhonovsky MA, Oleynik EE, Tortika AS, Senkov ON. Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J Alloys Compd. 2015;628:170. https://doi.org/10.1016/j.jallcom.2014.12.157.

Zhu ZG, Ma KH, Wang Q, Shek CH. Compositional dependence of phase formation and mechanical properties in three CoCrFeNi-(Mn/Al/Cu) high entropy alloys. Intermetallcs. 2016;79:1. https://doi.org/10.1016/j.intermet.2016.09.003.

Tung CC, Yeh JW, Shun T, Chen SK, Huang YS, Chen HC. On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater Lett. 2007;61(1):1. https://doi.org/10.1016/j.matlet.2006.03.140.

Kao YF, Chen SK, Chen TJ, Chu PC, Yeh JW, Lin SJ. Electrical, magnetic, and Hall properties of AlxCoCrFeNi high-entropy alloys. J Alloys Compd. 2011;509(5):1607. https://doi.org/10.1016/j.jallcom.2010.10.210.

Chen MR, Lin SJ, Yeh JW, Chen SK, Huang YS, Tu CP. Microstructure and properties of Al0.5CoCrCuFeNiTix (x = 0–2.0) high-entropy alloys. Mater Trans. 2006;47(5):1395. https://doi.org/10.2320/matertrans.47.1395.

Zhou YJ, Zhang Y, Wang YL, Chen GL. Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl Phys Lett. 2007;90(18):181904. https://doi.org/10.1063/1.2734517.

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK. Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater. 2008;10(6):534. https://doi.org/10.1002/adem.200700240.

Peng Z, Luo ZB, Li BW, Li JF, Luan HW, Gu JL, Wu Y, Yao KF. Microstructure and mechanical properties of lightweight AlCrTiV0.5Cux high-entropy alloys. Rare Met. 2022;41(6):2016. https://doi.org/10.1007/s12598-021-01940-9.

Shun TT, Chang LY, Shiu MH. Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys. Mater Sci Eng A. 2012;556:170. https://doi.org/10.1016/j.msea.2012.06.075.

Wu H, Huang S, Zhu C, Zhu H, Xie Z. Influence of Cr content on the microstructure and mechanical properties of CrxFeNiCu high entropy alloys. Prog Nat Sci Mater Int. 2020;30(2):239. https://doi.org/10.1016/j.pnsc.2020.01.012.

Zhang M, Ma Y, Dong W, Liu X, Lu Y, Zhang Y, Li R, Wang Y, Yu P, Gao Y, Li G. Phase evolution, microstructure, and mechanical behaviors of the CrFeNiAlxTiy medium-entropy alloys. Mater Sci Eng A. 2020;771:138566. https://doi.org/10.1016/j.msea.2019.138566.

Hu Z, Zhan Y, Zhang G, She J, Li C. Effect of rare earth Y addition on the microstructure and mechanical properties of high entropy AlCoCrCuNiTi alloys. Mater Des. 2010;31(3):1599. https://doi.org/10.1016/j.matdes.2009.09.016.

Varalakshmi S, Kamaraj M, Murty BS. Processing and properties of nanocrystalline CuNiCoZnAlTi high entropy alloys by mechanical alloying. Mater Sci Eng A. 2010;527(4–5):1027. https://doi.org/10.1016/j.msea.2009.09.019.

Wang XF, Zhang Y, Qiao Y, Chen GL. Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys. Intermetallics. 2007;15(3):357. https://doi.org/10.1016/j.intermet.2006.08.005.

Yang T, Zhao Y, Liu W, Kai J, Liu C. L12-strengthened high-entropy alloys for advanced structural application. J Mater Res. 2018;33:2983. https://doi.org/10.1557/jmr.2018.186.

Gwalani B, Choudhuri D, Soni V, Ren Y, Styles M, Hwang JY, Nam SJ, Ryu H, Hong SH, Banerjee R. Cu assisted stabilization and nucleation of L12 precipitates in Al0.3CuFeCrNi2 fcc-based high entropy alloy. Acta Mater. 2017;129:170. https://doi.org/10.1016/j.actamat.2017.02.053.

Borkar T, Gwalani B, Choudhuri D, Mikler CV, Yannetta CJ, Chen X, Ramanujan RV, Styles MJ, Gibson MA Banerjee R. A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 15) complex concentrated alloys: Microstructure, microhardness, and magnetic properties. Acta Mater. 2016. https://doi.org/10.1016/j.actamat.2016.06.025.

Liang YJ, Wang L, Wen Y, Cheng B, Wu Q, Cao T, Xiao Q, Xue Y, Sha G, Wang Y, Ren Y, Li X, Wang L, Wang F, Cai H. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys. Nat Commun. 2018;9:4063. https://doi.org/10.1038/s41467-018-06600-8.

Jumaev E, Abbas MA, Mun SC, Song G, Hong SJ, Kim KB. Nano-scale structural evolution of quaternary AlCrFeNi based high entropy alloys by the addition of specific minor elements and its effect on mechanical characteristics. J Alloys Compd. 2021;868:159217. https://doi.org/10.1016/j.jallcom.2021.159217.

Gao S, Kong T, Zhang M, Chen X, Sui YW, Ren YJ, Qi JQ, Wei FX, He YZ, Meng QK, Sun Z. Effects of titanium addition on microstructure and mechanical properties of CrFeNiTix (x = 0.2–0.6) compositionally complex alloys. J Mater Res. 2019;34:819. https://doi.org/10.1557/jmr.2019.40.

Yang HX, Li JS, Guo T, Wang WY, Kou HC, Wang J. Evolution of microstructure and hardness in a dual-phase Al0.5 CoCrFeNi high-entropy alloy with different grain sizes. Rare Met. 2020;39(2):156. https://doi.org/10.1007/s12598-019-01320-4.

Ding J, Xu H, Li X, Liu M, Zhang T. The similarity of elements in multi-principle element alloys based on a new criterion for phase constitution. Mater Des. 2021;207:109849. https://doi.org/10.1016/j.matdes.2021.109849.

Bai X, Fang W, Chang R, Yu H, Zhang X, Yin F. Effect of Al and Ti addition on precipitation behaivor and mechanical properties of Co35Cr25Fe40−xNix TRIP high entropty alloys. Mater Sci Eng A. 2019;767:138403. https://doi.org/10.1016/j.msea.2019.138403.

Zhang L, Zhou Y, Jin X, Du X, Li B. Precipitation-hardened high entropy alloys with exellent tensile properties. Mater Sci Eng A. 2018;732:186. https://doi.org/10.1016/j.msea.2018.06.102.

He JY, Wang H, Huang HL, Xu XD, Chen MW, Wu Y, Liu XJ, Nieh TG, An K, Lu ZP. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016;102:187. https://doi.org/10.1016/j.actamat.2015.08.076.

Wang L, Wu X, Su H, Deng B, Liu G, Han Z, Su Y, Huang Y, Zhang Y, Shen J, Zhang G. Microstructure and mechanical property of novel L12 nanoparticles-strengthened CoFeNi-based medium entropy alloys. Mater Sci Eng A. 2022;840:142917. https://doi.org/10.1016/j.msea.2022.142917.

Tong Y, Chen D, Han B, Wang J, Feng R, Yang T, Zhao C, Zhao YL, Guo W, Shimizu Y, Liu CT, Liaw PK, Inoue K, Nagai Y, Hu A, Kai JJ. Outstanding tensile properties of a precipitation-strengthened FeCoNiCrTi0.2 high-entropy alloy at room and cryogenic temperatures. Acta Mater. 2019;165:228. https://doi.org/10.1016/j.actamat.2018.11.049.

Mehranpour MS, Shahmir H, Derakhshandeh A, Nili-Ahmadabadi M. Significance of Ti addition on precipitation in CoCrFeNiMn high-entropy alloy. J Alloys Compd. 2021;888:2. https://doi.org/10.1016/j.jallcom.2021.161530.

Niu M, Zhou G, Wang W, Shahzad MB, Shan Y, Yang K. Precipitate evolution and strengthening behavior during aging process in a 2.5 GPa grade maraging steel. Acta Mater. 2019;179:296. https://doi.org/10.1016/j.actamat.2019.08.042.

Jumaev E, Hong SH, Kim JT, Park HJ, Kim YS, Mun SC, Park JY, Song G, Lee JK, Min BH, Lee T, Kim KB. Chemical evolution-induced strengthening on AlCoCrNi dual-phase high-entropy alloy with high specific strength. J Alloys Compd. 2019;777:828. https://doi.org/10.1016/j.jallcom.2018.11.057.

Acknowledgements

This work was financially supported by the National Research Foundation of Korea (NRF) grant funded by the Korean Government (Ministry of Science and ICT) (Nos. 2018R1A2B3007167 and 2021R1C1C1006279) and the Agency for Presidential Educational Institutions of the Republic of Uzbekistan (No. 3/2022).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dilshodbek, Y., Hong, S.H., Abbas, M.A. et al. Evolution of microstructure and mechanical characteristics of (CrFeNiCu)100–xTix high-entropy alloys. Rare Met. 42, 3088–3098 (2023). https://doi.org/10.1007/s12598-023-02286-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02286-0