Abstract

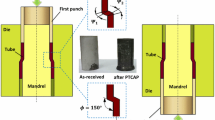

In the present work, Zn–10Al–2Cu–0.05Ti (ZA10) alloy tubes with a diameter of 12.5 mm and wall thickness of 1.2 mm were fabricated by one-pass and double-pass Conform continuous extrusion. A stabilizing heat treatment [350 °C, 30 min (furnace cooling) + 120 °C, 12 h (air cooling)] was also applied to some of the double-pass tubes to improve the quality of their weld seams. The yield strength, ultimate tensile strength, elongation and expansion ratio of the one-pass continuous extrusion tube were 268.4 MPa, 294.3 MPa, 13.8% and 5.5%, respectively. Double-pass continuous extrusion improved these values to 278.4 MPa, 317.2 MPa, 15.4% and 11.4%, respectively. Double-pass tubes also had fewer aggregations of Al-α precipitates along the welding seam, which improved seam quality and caused cracks to appear in the matrix, away from the weld-affected zone, during expansion testing. Heat-treated double-pass tubes exhibited superior yield strength (283.9 MPa) and ultimate tensile strength (328.5 MPa) but lower elongation (10.2%) and expansion ratios (10.3%). Additionally, the heat-treated tubes exhibited markedly lower elongation at room temperature due to the remarkable blockage of dislocation motions by fine-scale lamellar (α + η) eutectoid structures and a lower size effect when stretched.

Similar content being viewed by others

References

Green D. Continuous extrusion-forming of wire sections. J Inst Metals. 1972;100:296.

Etherington C. Conform: a new concept for the continuous extrusion forming of metals. J Eng Ind. 1974;75(3):13113.

Kim YH, Cho JR, Jeong HS, Kim KS, Yoon SS. A study on optimal design for Conform process. J Mater Process Technol. 1998;80(98):671.

Cho JR, Jeong HS. Conform process: surface separation, curling and process characteristics to the wheel diameter. J Mater Process Technol. 2003;136(1):217.

Lu J, Saluja N, Riviere AL, Zhou Y. Computer modeling of the continuous forming extrusion process of AA6061 alloy. J Mater Process Technol. 1998;79(1–3):200.

Raab GJ, Valiev RZ, Lowe TC, Zhu YT. Continuous processing of ultrafine grained Al by ECAP–Conform. Mater Sci Eng A. 2004;382(1):30.

Xu C, Schroeder S, Berbon PB, Langdon TG. Principles of ECAP–Conform as a continuous process for achieving grain refinement: application to an aluminum alloy. Acta Mater. 2010;58(4):1379.

Katsas S, Dashwood R, Todd G, Jackson M, Grimes R. Characterization of Conform™ and conventionally extruded Al–4Mg–1Zr. Effect of extrusion route on superplasticity. J Mater Sci. 2010;45(15):4188.

Cao FR, Wen JL, Ding H, Wang ZD, Li YL, Guan RG, Hou H. Force analysis and experimental study of pure aluminum and Al–5%Ti–1%B alloy continuous expansion extrusion forming process. Trans Nonferrous Met Soc China. 2013;23(1):201.

Kong X, Zhang H, Ji X. Microstructures and mechanical properties evolution of an Al–Fe–Cu alloy processed by repetitive continuous extrusion forming. Mater. Sci. Eng. A. 2014;612(33):131.

Ji X, Zhang H, Luo S, Jiang F, Fu D. Microstructures and properties of Al–Mg–Si alloy overhead conductor by horizontal continuous casting and continuous extrusion forming process. Mater Sci Eng A. 2016;649(1):128.

Zhu C, Ma A, Jiang J, Li X, Song D, Yang D, Yuan Y, Chen J. Effect of ECAP combined cold working on mechanical properties and electrical conductivity of Conform-produced Cu–Mg alloys. J Alloys Compd. 2014;582(1):135.

Feng H, Jiang H, Yan D, Rong L. Effect of continuous extrusion on the microstructure and mechanical properties of a CuCrZr alloy. Mater Sci Eng A. 2013;582(10):219.

He Y, Gao F, Song B, Li J, Fu R, Wu G. Production of very fine grained Mg–3%Al–1%Zn alloy by continuous extrusion forming (Conform). Adv Eng Mater. 2010;12(9):843.

Zhang H, Yan Q, Li L. Microstructures and tensile properties of AZ31 magnesium alloy by continuous extrusion forming process. Mater Sci Eng A. 2008;486(1):295.

Semenova IP, Polyakov AV, Raab GI, Lowe TC, Valiev RZ. Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-Conform. J Mater Sci. 2012;47(22):7777.

Thomas BM, Derguti F, Jackson M. Continuous extrusion of a commercially pure titanium powder via the Conform process. Metal Sci J. 2016;33(7):899.

Gunderov DV, Polyakov AV, Semenova IP, Raab GI, Churakova AA, Gimaltdinova Sabirov I, Segurado J, Sitdikov VD, Alexandrov IV, Enikeev NA, Valiev RZ. Evolution of microstructure, macrotexture and mechanical properties of commercially pure Ti during ECAP-Conform processing and drawing. Mater Sci Eng. A. 2013;562(1):128.

Al-Maharbi M, Karaman I, Purcek G. Flow response of a severe plastically deformed two-phase zinc–aluminum alloy. Mater Sci Eng A. 2010;527(3):518.

Costa EMD, Costa CED, Vecchia FD, Rick C, Scherer M, Santos CA, Dedavid BA. Study of the influence of copper and magnesium additions on the microstructure formation of Zn–Al hypoeutectic alloys. J Alloys Compd. 2009;488(1):89.

Prasad BK, Patwardhan AK, Yegneswaran AH. Microstructural modifications through compositional alterations and their influence on the mechanical and sliding wear properties of zinc-based alloys. Script Mater. 1997;37(3):323.

Aydın M. High-cycle fatigue behavior of severe plastically deformed binary Zn–60Al alloy by equal-channel angular extrusion. J Mater Process Technol. 2012;212(8):1780.

Qiu X, Yang Q, Guan K, Bu F, Cao ZY, Liu YB, Meng J. Microstructures and tensile properties of Mg–Zn–(Gd)–Zr alloys extruded at various temperatures. Rare Met. 2017;36(12):962.

Hutchinson WB, Barnett MR. Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Script Mater. 2010;63(7):737.

Chapuis A, Driver JH. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011;59(5):1986.

Yang CF, Pan JH, Lee TH. Work-softening and anneal-hardening behaviors in fine-grained Zn–Al alloys. J Alloys Compd. 2009;468(1–2):230.

Yu J, Zhao G, Cui W, Zhang C, Chen L. Microstructural evolution and mechanical properties of welding seams in aluminum alloy profiles extruded by a porthole die under different billet heating temperatures and extrusion speeds. J Mater Process Technol. 2017;247:214.

Lin GY, Zhang R, Wang L, Lei YX, He JJ. Effects of stabilizing heat treatment on microstructures and creep behavior of Zn–10Al–2Cu–0.02Ti alloy. Trans Nonferrous Met Soc China. 2013;23(1):86.

Wu Z, Sandlöbes S, Wu L, Hu W, Gottstein G, Korte-Kerzel S. Mechanical behaviour of Zn–Al–Cu–Mg alloys: deformation mechanisms of as-cast microstructures. Mater Sci Eng A. 2016;651:675.

Zhu YH, Lee WB. Tensile deformation and phase transformation of furnace-cooled Zn–Al based alloy. Mater Sci Eng A. 2000;293(1):95.

Zhu YH, Lee WB, To S. Tensile deformation-induced phase transformation in cast Zn–Al-based alloy (ZnAl7Cu3). Mater Res Bull. 2003;38(14):1851.

Sikand R, Kumar AM, Sachdev AK, Luo AA, Jain V, Gupta AK. AM30 porthole die extrusions—a comparison with circular seamless extruded tubes. J Mater Process Technol. 2009;209(18–19):6010.

Kim KJ, Lee CH, Yang DY. Investigation into the improvement of welding strength in three-dimensional extrusion of tubes using porthole dies. J Mater Process Technol. 2002;130(2):426.

Li L, Zhang H, Zhou J, Duszczyk J, Li GY, Zhong ZH. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams. Mater Des. 2008;29(6):1190.

Acknowledgements

This study was financially supported by the National 11th Five-Year Science and Technology Support Program of China (No. 2009BAE71B00), and Hunan Science and Technology Plan Key Project (No. 2012GK4012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, GY., Xiao, MQ., Feng, D. et al. Microstructural and mechanical properties of ZA10 alloy tubes and their weld seams prepared by Conform continuous extrusion. Rare Met. 39, 707–715 (2020). https://doi.org/10.1007/s12598-020-01437-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01437-x