Abstract

This study investigated the morphology, structure and tribological properties of the three samples produced by anodic oxidation of Ti10V2Fe3Al in a sulfuric/phosphoric acid electrolyte (SPA), a near-neutral sodium tartrate electrolyte without nanoparticles (STA) and a near-neutral sodium tartrate electrolyte with polytetrafluoroethylene (PTFE) nanoparticles (CA) in suspension. The STA film had a surface full of bulges and cracks, the SPA film was porous, and the CA film was nanoporous. The SPA film was mainly composed of anatase TiO2, whereas the STA and CA films were mainly amorphous TiO2 with little anatase. The tribological tests indicated that the SPA sample had a lower wear resistance than the titanium alloy substrate, which was attributed to the shedding of abrasive debris, leading to rapid wear. Both STA and CA samples exhibited much lower wear rates than the titanium alloy substrate, and CA sample displayed the lowest wear rate attributed to the formation of a lubricating layer by PTFE nanoparticles. The wear mechanisms are proposed.

Similar content being viewed by others

References

Jin J, Li XH, Wu JW, Lou BY. Improving tribological and corrosion resistance of Ti6Al4V alloy by hybrid microarc oxidation/enameling treatments. Rare Met. 2018;37(1):26.

Qu WT, Sun XG, Hui SX, Wang ZG, Li Y. High-temperature deformation behavior of a beta Ti–3.0Al–3.5Cr–2.0Fe–0.1B alloy. Rare Met. 2018;7(3):217.

Mohan L, Anandan C. Wear and corrosion behavior of oxygen implanted biomedical titanium alloy Ti–13Nb–13Zr. Appl Surf Sci. 2013;282:281.

Levingstone TJ, Ardhaoui M, Benyounis K, Looney L, Stokes JT. Plasma sprayed hydroxyapatite coatings: understanding process relationships using design of experiment analysis. Surf Coat Technol. 2015;283:29.

Wu Y, Wang AH, Zhang Z, Xia HB, Wang YN. Wear resistance of in situ synthesized titanium compound coatings produced by laser alloying technique. Surf Coat Technol. 2014;258:711.

Wang S, Liao Z, Liu Y, Liu W. Different tribological behaviors of titanium alloys modified by thermal oxidation and spraying diamond like carbon. Surf Coat Technol. 2014;252:64.

Dominik M, Lesniewski A, Janczuk M, Niedziolka-Jonsson J, Holdynski M, Wachnicki L, Godlewski M, Bock WJ, Smietana M. Titanium oxide thin films obtained with physical and chemical vapour deposition methods for optical biosensing purposes. Biosens Bioelectron. 2017;93:102.

Komiya S, Sakamoto K, Ohtsu N. Structural changes of anodic layer on titanium in sulfate solution as a function of anodization duration in constant current mode. Appl Surf Sci. 2014;296:163.

Quintero D, Galvis O, Calderón JA, Gómez MA, Castaño JG, Echeverría F, Habazaki H. Control of the physical properties of anodic coatings obtained by plasma electrolytic oxidation on Ti6Al4V alloy. Surf Coat Technol. 2015;283:210.

Si HY, Sun ZH, Kang X, Zi WW, Zhang HL. Voltage-dependent morphology, wettability and photocurrent response of anodic porous titanium dioxide films. Microporous Mesoporous Mater. 2009;119(1–3):75.

Oh HJ, Chi CS. Eu–N-doped TiO2 photocatalyst synthesized by micro-arc oxidation. Mater Lett. 2012;86:31.

Park YJ, Shin KH, Song HJ. Effects of anodizing conditions on bond strength of anodically oxidized film to titanium substrate. Appl Surf Sci. 2007;253(14):6013.

Manjaiah M, Laubscher RF. Effect of anodizing on surface integrity of Grade 4 titanium for biomedical applications. Surf Coat Technol. 2017;310:263.

Kuromoto NK, Simão RA, Soares GA. Titanium oxide films produced on commercially pure titanium by anodic oxidation with different voltages. Mater Charact. 2007;58(2):114.

Wang J, Chen J. The effect of silane on the microstructure, corrosion, and abrasion resistances of the anodic films on Ti alloy. J Mater Eng Perform. 2016;25(4):1594.

Sul YT, Johansson CB, Jeong Y, Albrektsson T. The electrochemical oxide growth behaviour on titanium in acid and alkaline electrolytes. Med Eng Phys. 2001;23(5):329.

Aliofkhazraei M, Sabour Rouhaghdam A, Shahrabi T. Abrasive wear behaviour of Si3N4/TiO2 nanocomposite coatings fabricated by plasma electrolytic oxidation. Surf Coat Technol. 2010;205:S41.

Mu M, Liang J, Zhou X, Xiao Q. One-step preparation of TiO2/MoS2 composite coating on Ti6Al4V alloy by plasma electrolytic oxidation and its tribological properties. Surf Coat Technol. 2013;214:124.

Mu M, Zhou X, Xiao Q, Liang J, Huo X. Preparation and tribological properties of self-lubricating TiO2/graphite composite coating on Ti6Al4V alloy. Appl Surf Sci. 2012;258(22):8570.

Lorenzo-Martin C, Ajayi OO. Effect of SiC particle impact nano-texturing on tribological performance of 304L stainless steel. Appl Surf Sci. 2014;315:287.

Lu X, Blawert C, Huang Y, Ovri H, Zheludkevich ML, Kainer KU. Plasma electrolytic oxidation coatings on Mg alloy with addition of SiO2 particles. Electrochim Acta. 2016;187:20.

Rudnev VS, Vaganov-Vil’kins AA, Yarovaya TP, Pavlov AD. Polytetrafluoroethylene-oxide coatings on aluminum alloys. Surf Coat Technol. 2016;307:1249.

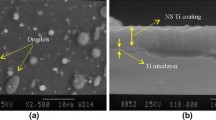

Wu G, Yu M, Liu J, Li S, Wu L, Zhang Y. Surface characteristics of anodic oxide films fabricated in acid and neutral electrolytes on Ti–10V–2Fe–3Al alloy. Surf Interface Anal. 2013;45(2):661.

Li Q, Yang W, Liu C, Wang D, Liang J. Correlations between the growth mechanism and properties of micro-arc oxidation coatings on titanium alloy: effects of electrolytes. Surf Coat Technol. 2017;316:162.

Wu Z, Xing Y, Huang P, Liu L. Tribological properties of dimple-textured titanium alloys under dry sliding contact. Surf Coat Technol. 2017;309:21.

Chan CW, Lee S, Smith GC, Donaghy C. Fibre laser nitriding of titanium and its alloy in open atmosphere for orthopaedic implant applications: investigations on surface quality, microstructure and tribological properties. Surf Coat Technol. 2017;309:628.

Wu L, Liu JH, Wu GL, Li SM, Yu M. Growth behaviour of anodic oxide film on titanium alloy. Surf Eng. 2014;31(12):904.

Liu J, Yi J, Li S, Yu M, Wu G, Wu L. Effect of electrolyte concentration on morphology, microstructure and electrochemical impedance of anodic oxide film on titanium alloy Ti–10V–2Fe–3Al. J Appl Electrochem. 2010;40(8):1545.

Habazaki H, Uozumi M, Konno H, Shimizu K, Skeldon P, Thompson GE. Crystallization of anodic titania on titanium and its alloys. Corros Sci. 2003;45(9):2063.

Zhu XF, Li DD, Song Y, Xiao YH. The study on oxygen bubbles of anodic alumina based on high purity aluminum. Mater Lett. 2005;59(24–25):3160.

Li SM, Yu XM, Liu JH, Yu M, Wu L, Yang K. Microstructure and abrasive wear behaviour of anodizing composite films containing SiC nanoparticles on Ti6Al4V alloy. J Cent South Univ. 2014;21(12):4415.

Li S, Yao W, Liu J, Yu M, Wu L, Ma K. Study on anodic oxidation process and property of composite film formed on Ti–10V–2Fe–3Al alloy in SiC nanoparticle suspension. Surf Coat Technol. 2015;277:234.

Fatimah S, Kamil MP, Kwon JH, Kaseem M, Ko YG. Dual incorporation of SiO2 and ZrO2 nanoparticles into the oxide layer on 6061 Al alloy via plasma electrolytic oxidation: coating structure and corrosion properties. J Alloy Compd. 2017;707:358.

Simka W, Sadkowski A, Warczak M, Iwaniak A, Dercz G, Michalska J, Maciej A. Characterization of passive films formed on titanium during anodic oxidation. Electrochim Acta. 2011;56(24):8962.

Bhagath Singh GVP, Subramaniam KVL. Quantitative XRD study of amorphous phase in alkali activated low calcium siliceous fly ash. Constr Build Mater. 2016;124:139.

Zhang J, Liu M, Song J, Deng C, Deng C. Microstructure and corrosion behavior of Fe-based amorphous coating prepared by HVOF. J Alloy Compd. 2017;721:506.

Wu H, Lu X, Long B, Wang X, Wang J, Jin Z. The effects of cathodic and anodic voltages on the characteristics of porous nanocrystalline titania coatings fabricated by microarc oxidation. Mater Lett. 2005;59(2–3):370.

Diamanti MV, Pedeferri MP. Effect of anodic oxidation parameters on the titanium oxides formation. Corros Sci. 2007;49(2):939.

Thongsuwan W, Singjai P. Influence of TiO2/Fe2O3 interfacial layers on optical properties under visible light. Surf Coat Technol. 2016;306:49.

Lakshmi RV, Aruna ST, Anandan C, Bera P, Sampath S. EIS and XPS studies on the self-healing properties of Ce-modified silica-alumina hybrid coatings: evidence for Ce(III) migration. Surf Coat Technol. 2017;309:363.

Fei J, Zhang C, Luo D, Cui Y, Li H, Lu Z, Huang J. Bonding TiO2 array on carbon fabric for outstanding mechanical and wear resistance of carbon fabric/phenolic composite. Surf Coat Technol. 2017;317:75.

Lee YC, Hong YP, Lee HY, Kim H, Jung YJ, Ko KH, Jung HS, Hong KS. Photocatalysis and hydrophilicity of doped TiO2 thin films. J Colloid Interface Sci. 2003;267(1):127.

Yi JL, Liu JH, Li SM, Yu M, Wu GL, Wu L. Morphology and growth of porous anodic oxide films on Ti–10V–2Fe–3Al in neutral tartrate solution. J Cent South Univ Technol. 2011;18(1):6.

Arman SY, Omidvar H, Tabaian SH, Sajjadnejad M, Fouladvand S, Afshar S. Evaluation of nanostructured S-doped TiO2 thin films and their photoelectrochemical application as photoanode for corrosion protection of 304 stainless steel. Surf Coat Technol. 2014;251:162.

Qiao LP, Lou J, Zhang SF, Qu B, Chang WH, Zhang RF. The entrance mechanism of calcium and phosphorus elements into micro arc oxidation coatings developed on Ti6Al4V alloy. Surf Coat Technol. 2016;285:187.

Song H, Yu H, Zhu L, Xue L, Wu D, Chen H. Durable hydrophilic surface modification for PTFE hollow fiber membranes. React Funct Polym. 2017;114:110.

Aliasghari S, Skeldon P, Thompson GE. Plasma electrolytic oxidation of titanium in a phosphate/silicate electrolyte and tribological performance of the coatings. Appl Surf Sci. 2014;316:463.

Sun Y. Tribological rutile-TiO2 coating on aluminium alloy. Appl Surf Sci. 2004;233(1–4):328.

Tang A, Wang M, Huang W, Wang X. Composition design of Ni–nano-Al2O3–PTFE coatings and their tribological characteristics. Surf Coat Technol. 2015;282:121.

Zhang R, Zhao J, Liang J. A novel multifunctional PTFE/PEO composite coating prepared by one-step method. Surf Coat Technol. 2016;299:90.

Wu L, Wen C, Zhang G, Liu J, Ma K. Influence of anodizing time on morphology, structure and tribological properties of composite anodic films on titanium alloy. Vacuum. 2017;140:176.

Zhang DY, Zhang PB, Lin P, Dong GN, Zeng QF. Tribological properties of self-lubricating polymer-steel laminated composites. Tribol Trans. 2013;56(6):908.

Zhang D, Dong G, Chen Y, Zeng Q. Electrophoretic deposition of PTFE particles on porous anodic aluminum oxide film and its tribological properties. Appl Surf Sci. 2014;290:466.

Acknowledgements

This study was financially supported by the Chongqing Research Program of Basic Research and Frontier Technology (No. cstc2016jcyjA0388), the National Natural Science Foundation of China (No. 51701029), the Research and Development Project from COMAC and BOEING (No. 2017-GT-088), China Postdoctoral Science Foundation Funded Project (Nos. 2017M620410 and 2018T110942), the Chongqing Postdoctoral Scientific Research Foundation (No. Xm2017010) and the Fundamental Research Funds for the Central Universities (No. 2018CDGFCL005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, L., Liu, L., Zhan, Q. et al. Morphology, microstructure and tribological properties of anodic films formed on Ti10V2Fe3Al alloy in different electrolytes. Rare Met. 40, 1–12 (2021). https://doi.org/10.1007/s12598-019-01296-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01296-1