Abstract

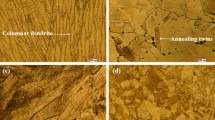

Microstructure and texture in 6016 aluminum alloy during hot compression were researched with a uniaxial compression experiment. Through the electron back-scattered diffraction (EBSD) and X-ray diffraction (XRD) analysis technology, it is shown that the subgrain nucleation and recrystallization occur in 6016 aluminum alloy during hot compressing, and strong rolling textures such as 〈110〉 fiber texture, Brass, S, and Goss form. With the deformation passes increasing, 〈110〉 fiber texture, Brass and S are enhanced. In the heat preservation stage after deformation, recrystallization continues until heat preservation for 60 s, and a duplex microstructure of deformation and recrystallization grains is built. At the beginning of heat preservation, recrystallization grains with the Goss texture and random orientation are formed in original grains with S or Brass texture, which makes the volume fraction of S and Brass texture decrease. Then, the complex grain growth process makes the volume fraction of Brass, S, and Goss texture increase, while that of random orientation decrease.

Similar content being viewed by others

References

Hirth SM, Marshall GJ. Effects of Si on the aging behavior and formability of aluminum alloys based on AA6016 materials. Sci Eng. 2001;A319:452.

Bottema J, Lahaye C, Baartman R, Zhuang L. Recent developments in AA6016 aluminum type body sheet product. In: 1998 SAE International Congress and Exposition, Detroit, Michigan; 1998. 900.

Falahati A, Lang P, Kozeschnik E. Precipitation in Al-alloy 6016-the role of excess vacancies. In: 7th International Conference on Processing and Manufacturing of Advanced Materials, Quebec; 2012. 317.

Inagaki H. Texture development in 6000 series Al–Mg–Si alloys for car body panels. In: 3rd International Conference on Recrystallization and Grain Growth, Jeju Island, South Korea; 2007. 77.

Engler O, Hirsch J. Texture control by thermomechanical processing of AA6xxx A1–Mg–Si sheet alloys for automotive applications—a review. Mater Sci Eng. 2002;336(1–2):249.

Mahabunphachai S, Koc M. Investigations on forming of aluminum 5052 and 6061 sheet alloys at warm temperatures. Mater Design. 2010;31(5):2422.

Kim WJ, Yoo SJ. Enhanced ductility and deformation mechanisms of ultrafinegrained Al–Mg–Si alloy in sheet form at warm temperatures. Scripta Mater. 2009;61(2):125.

Qi WJ, Wang SC, Chen XM, Nong D, Zhou Z. Effective nucleation phase and grain refinement mechanism of Al–5Ti–1B master alloy. Chin J Rare Met. 2013;37(2):179.

Zhang XM, Ke B, Tang JG, Liu SD, Deng YL. Effects of Mn content on microstructure and mechanical properties of 6061 aluminum alloy. Chin J Mater Res. 2013;27(4):337.

Dai GQ, Qu WQ, Zhuang HS. Structure performance and diffusion mechanism of aluminum alloy heat pipe low-temperature diffusion brazing joints. Chin J Mater Res. 2013;37(6):851.

Lin L, Zhen ZQ, Li JF. Effect of aging treatments on the mechanical properties and corrosion behavior of 6156 aluminum alloy. Rare Met Mater Eng. 2012;41(6):1005.

Wu XF, Zhang GG, Wu FF. Microstructure and dry sliding wear behavior of cast Al–Mg2Si in situ metal matrix composite modified by Nd. Rare Met. 2013;32(3):284.

Wu XF, Liu HX, Li HO, Li Q, Hu SG, Xi ZF, Zhao J. Fabrication of 150-nm Al0.48In0.52As/Ga0.47In0.53As mHEMTs on GaAs substrates. Sci China Phys Mech Astron. 2012;55(12):2389.

Tucker MT, Horstemeyer MF, Whittington WR, Solanki KN, Gullett PM. The effect of varying strain rates and stress states on the plasticity, damage and fracture of aluminum alloys. Mech Mater. 2010;42(10):895.

Loucif A, Figueiredo RB, Baudin T, Brisset F, Chemam R, Langdon TG. Ultrafine grains and the Hall-Petch relationship in an Al–Mg–Si alloy processed by high-pressure torsion. Mater Sci Eng A. 2012;532(15):139.

Loucif A, Baudin T, Figueiredo RB, Brisset F, Helbert A, Chemam R, Langdon TG. Microstructure and microtexture evolution with aging treatment in an Al–Mg–Si alloy severely deformed by HPT. J Mater Sci. 2013;48(13):4573.

Chen Y, Tian N, Zhao G, Liu CM, Zuo L. Evolution of {001} 〈110〉 orientation and related lattice rotation of Al alloy 6111 during rolling. Trans Nonferr Met Soc China. 2007;17(3):523.

Chen Y, Tian N, Zhao G, Liu CM, Zuo L. Texture evolvement of aluminum alloy 6111 during cold rolling. J Northeast Univ (Nat Sci). 2006;27(1):41.

Chen Y, Tian N, Zhao G, Liu CM, Zuo L. Recrystallization texture in cool rolled sheet of Al alloy 6111 after solution treatment. Chin J Nonferr Met. 2006;16(2):333.

Chen Y, Tian N, Zhao G, Liu CM, Zuo L. Effect of pre-heat treatments on cold rolling and recrystallization textures in Al alloy 6111. Chin J Nonferr Met. 2006;16(8):1411.

Li XL, Chen JH, Liu CH, Feng JN, Wang SH. Effects of T6 and T78 tempers on the microstructures and properties of A1–Mg–Si–Cu alloys. Acta Metal Sin. 2013;49(2):243.

Li SL, Huang ZQ, Jiang FL, Chen WP, Liu ZM, Qi WJ. Effect of solution temperature on microstructure and property of a 6061 aluminum alloy. Trans Mater Heat Treat. 2013;34(5):131.

Ma MT, Bi YX, You JH, Lu HZ. Research progress of property and its application of aluminum alloy auto sheet. Mater Mech Eng. 2010;34(6):1.

Zhang YM, Zhou Y, Jin QL. Superplastic study of 5182 and 6016 industrial aluminum alloy. Trans Mater Heat Treat. 2004;25(4):33.

Feng JN, Chen JH, Liu CH, Liao YF, Li XL. Effects of pre-aging treatments on the microstructures and properties before and after paint bake cycle for a 6016 aluminum alloy. J Chin Electron Microsc Soc. 2012;31(6):461.

Ying L, Shen GZ, Hu P, Wang AD, Ma L, Chang Y. Research on bake hardening behavior of AA6016 aluminum alloy sheets. Chin J Mech Eng. 2011;47(10):19.

Zhang XM, Zhou N, Li L, Tang CP, Deng YL. Dynamic recrystallization of Mg-8Gd-3Y-0.6Zr alloy during hot-compression. Chin J Nonferr Met. 2009;19(12):2067.

Zhang JX, Feng W, Wen H, Ang GY. Mechanical behavior for 6016 aluminum alloy under hot-working conditions. Hot Work Technol. 2012;41(22):5.

Zhang JX, Feng W, Wen H, Ang GY. The flow stress feature and constitutive equation of 6016 aluminum alloy during hot compression. Adv Mater Res. 2012;538–541:1687.

Zhang JX, Wen H, Feng W, Ang GY, Liu JX. The flow stress characteristic and constitutive equation of 6016 aluminum alloy in warm forming. In: 2011 International Academic Conference on Machinery, Materials Science and Engineering Applications, Wuhan; 2011. 1112.

Mckenzie PWJ, Lapovok R. ECAP with back pressure for optimum strength and ductility in aluminum alloy 6016. Acta Mater. 2010;58(9):3212.

Bate PS, Humphreys FJ, Ridley N. Microstructure and texture evolution in the tension of superplastic Al-6Cu-0.4Zr. Acta Mater. 2005;53(10):3059.

Jazaeri H, Humphreys FJ. The transition from discontinuous to continuous recrystallization in some aluminium alloys II—annealing behaviour. Acta Mater. 2004;52(11):3251.

Jazaeri H, Humphreys FJ. The transition from discontinuous to continuous recrystallization in some aluminium alloys I—the deformed state. Acta Mater. 2004;52(11):3239.

Talamantes-Silva J, Abbod MF, Puchi Cabrera ES. Microstructure modelling of hot deformation of Al-1%Mg alloy. Mater Sci Eng A. 2009;525(1–2):147.

Bennett TA, Sidor J, Petrov RH, Kestens LAI. The effect of intermediate annealing on texture banding in aluminum alloy 6016. Adv Eng Mater. 2010;12(10):1018.

Liu X, Lou Y, Li LX, Zhu BW, He FY. Grain orientation and texture evolution of AZ31 magnesium alloy during hot compression. Chin J Nonferr Met. 2012;2(8):2141.

Yan WD, Fu GS, Chen GQ, Cheng CZ. Influence of deformation temperature on the texture of 1235 aluminum alloy after compression by EBSD technology. Mater Mech Eng. 2012;36(1):76.

Huang CQ, Diao JP, Deng H, Li BJ, Hu XH. Microstructure evolution of 6016 aluminum alloy during compression at elevated temperatures by hot rolling emulation. Trans Nonferr Met Soc China. 2013;23(6):1576.

Liu H, Zhou G, Liu CM, Zuo L. Effect of Mn addition on microstructures and properties of Al–Mg–Si–Cu system alloys for automotive body sheets. J Northeast Univ (Nat Sci). 2005;26(4):347.

Zhang XM, Deng YL, Liu Y, Tang JG, Zhou ZP. Microstructures and boundary distributions in Al polycrystals rolled at different temperatures. Acta Metal Sin. 2005;41(9):947.

Acknowledgments

This study was financially supported by the Original Program of Chongqing Foundational and Frontier Research Plan (No. cstc2013jcyjA70015) and the Science and Technology Research Program of Education Council of Chongqing (No. KJ080407).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, JX., Zhang, KL., Liu, YT. et al. Microstructure and texture evolution of 6016 aluminum alloy during hot compressing deformation. Rare Met. 33, 404–413 (2014). https://doi.org/10.1007/s12598-014-0331-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0331-2