Abstract

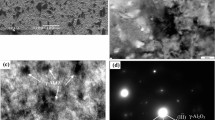

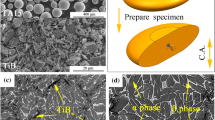

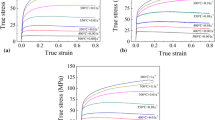

Hot compression behavior of TiC–Al2O3/Al composites was studied using the Gleeble-1500 system at a temperature range of 300–550 °C and at strain rate range of 0.01–10.00 s−1. The associated structural changes were studied by TEM observations. The results show that stress level decreases with deformation temperature increasing and strain rate decreasing, which can be represented by a Zener–Hollomon parameter in an exponent-type equation with hot deformation activation energy Q of 172.56 kJ·mol−1. Dynamic recovery occurs easily when strain rates are less than 10.00 s−1. Dynamic recrystallization can occur at strain rate of 10.00 s−1.

Similar content being viewed by others

References

Li B, Liu Y, Li J, Cao H, He L. Effect of sintering process on the microstructures and properties of in situ TiB2–TiC reinforced steel matrix composites produced by spark plasma sintering. J Mater Process Technol. 2010;210(1):91.

Omura N, Kobashi M, Kanetake N. Fabrication of the TiC/6061 aluminum alloy composite by the combination process of combustion reaction and vortex technique. J Jpn Inst Met. 2004;68(4):211.

Liu LZ, Ying GB, Zhu J, Lin H, Zhu CC. High-temperature compressive properties of TiC–TiB2/Cu composites prepared by self-propagating high-temperature synthesis. Rare Met. 2014;33(1):95.

Mortensen A, Kouzeli M, Weber L, San Marchi C. Corrigendum to: on the tensile behaviour of infiltrated alumina particle reinforced aluminium composites. Acta Materialia. 2003;51(20):6493.

Zhang H, Jin N, Chen J. Hot deformation behavior of Al–Zn–Mg–Cu–Zr aluminum alloys during compression at elevated temperature. Trans Nonferr Metals Soc China. 2011;21(3):437.

Talamantes-Silva J, Abbod MF, Cabrera ESP. Microstructure modelling of hot deformation of Al–1%Mg alloy. Mater Sci Eng A. 2009;525(1–2):147.

Zhang H, Li L, Yuan D, Peng DS. Hot deformation behavior of the new Al–Mg–Si–Cu aluminum alloy during compression at elevated temperatures. Mater Charact. 2007;58(2):168.

Rokni MR, Zarei-Hanzaki A, Roostaei AA, Abolhasani A. Constitutive base analysis of a 7075 aluminum alloy during hot compression testing. Mater Des. 2011;32(10):4955.

Wang QJ, Liu F, Du ZZ, Wang JY. Hot-compression deformation behavior of Cu–Cr–Zr alloy. Chin J Rare Met. 2014;37(5):687.

Sorensen NJ, Suresh S, Tvergaard V, Needleman A. Effects of reinforcement orientation on the tensile response of metal-matrix composites. Mater Sci Eng A. 1995;197(1):1.

Vasudevan AK, Richmond O, Zok F, Embury JD. The influence of hydrostatic pressure on the ductility of Al SiC composites. Mater Sci Eng A. 1989;107:63.

Cavaliere P, Cerri E, Leo P. Hot deformation and processing maps of a particulate reinforced 2618/Al2O3/20p metal matrix composite. Comp Sci Technol. 2004;64(9):1287.

Robi PS, Dixit US. Application of neural networks in generating processing map for hot working. J Mater Process Technol. 2003;142(1):289.

Ebrahimi GR, Zarei-Hanzaki A, Haghshenas M, Arabshahi H. The effect of heat treatment on hot deformation behaviour of Al 2024. J Mater Process Technol. 2008;206(1–3):25.

Jin N, Zhang H, Han Y, Wu WX, Chen JH. Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature. Mater Charact. 2009;60(6):530.

Yang XW, Lai ZH, Zhu JC, Liu Y, He D. Hot compressive deformation behavior of the as-quenched A357 aluminum alloy. Mater Sci Eng B. 2012;177(19):1721.

Liu XY, Pan QL, He YB, Li WB, Liang WJ, Yin ZM. Flow behavior and microstructural evolution of Al–Cu–Mg–Ag alloy during hot compression deformation. Mater Sci Eng A. 2009;500(1–2):150.

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ, Jensen DJ, Kassner ME, King WE, McNelley TR, McQueen HJ, Rollett AD. Current issues in recrystallization: a review. Mater Sci Eng A. 1997;238(2):219.

Gourdet S, Montheillet F. An experimental study of the recrystallization mechanism during hot deformation of aluminium. Mater Sci Eng A. 2000;283(1–2):274.

Acknowledgments

This study was financially supported by the Inner Mongolia Science and Technology Reward Foundation (No. 20101707), the Inner Mongolia Natural Science Foundation (No. 2013MS0804), the Inner Mongolia High School Scientific Research Foundation (No. NJZZ14056), and the Inner Mongolia University of Technology Foundation (No. ZD20120015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, RY., Shi, ZM. & Zhang, XM. Hot deformation behavior and microstructure evolution of TiC–Al2O3/Al composites. Rare Met. 34, 725–730 (2015). https://doi.org/10.1007/s12598-014-0274-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0274-7