Abstract

Hypersonic hydrogen-powered cruise vehicles offer promise for economical and reliable high-speed atmospheric transport. In recent years, several vehicle concepts have been developed in which the integration of fuel tanks is a major challenge, as they feature complex aerodynamic designs. In this work, we explore the viability of multi-lobe hydrogen tanks as a solution to obtain lightweight and volume-efficient structures. To do so, a parametric finite-element model was developed to fit multi-lobe geometries inside hypersonic vehicles. The parametric model was then incorporated into an optimization that minimizes the mass and maximizes the fuel capacity of the tank. The methodology is organized in two steps: the global search is driven by a two-level optimization consisting of a genetic algorithm with a nested gradient-based method; and a local search where each design is further improved to obtain a Pareto front. As presented in the results, this is a promising approach for designing multi-lobe tanks for complex geometries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Slender hypersonic craft have potential applications ranging from point-to-point transportation to low-cost reusable access to space. For civil transportation, they are considered to be the future technology for high-speed commercial travel to any location on the planet in less than 4 h. The successful design of a cruise hypersonic aircraft will depend on a detailed balance between structural design, aerodynamics, and propulsion.

Two major challenges when designing a hypersonic vehicle within the air atmosphere are thermal management and structural performance. Regarding the former, the aeroshell geometry determines the heat fluxes. In contrast to hypersonic blunt body capsules, cruise vehicles require a higher lift-to-drag (L/D) ratio, hence exhibiting a more slender shape. As a result, heat is dissipated through near-wall phenomena along the wetted surface instead of strong bow shocks, which would mainly heat the stagnation area. For this reason, the thermal protection system must deal with a significantly larger surface area. Beyond that, a sound structural design requires subsystems to be tightly integrated within the airframe. Specifically, the fuel tanks must be accommodated to the external aerodynamic surfaces and internal propulsive flowpaths, seeking a trade-off solution between internal volume and structural weight. This multi-functionality can be achieved using the multi-lobe concept, which is a promising solution for hypersonic vehicle architectures [1].

In the early stages of the Space Shuttle program (phase B), the tank configuration was conceived as a two-lobe system [2]. The orbiter configuration integrated the tanks as part of the fuselage, hence being subjected to all the structural loads. The analysis methods at the time did not enable a complete assessment of the structural performance, and the automated welding techniques were not satisfactory enough for the complex geometry of the cusp, formed by the intersection of the two cylinders. Years later, within the VentureStar program, Lockheed Martin developed the X-33 subscale technology demonstrator [3]. This vehicle had a dual-lobe and a quad-lobe fuel tank integrated in the fuselage. The composite liquid hydrogen (LH2) tank failed during testing, which inevitably led to delays and the subsequent cancelation of the program (Fig. 1).

In Europe, several projects were involved in the design of a hypersonic cruise vehicle. The LAPCAT MR2.4 vehicle [4] consists of a waverider lifting body with an integrated dorsal-mounted propulsion system. To be efficient during hypersonic cruise, the vehicle has leading edges with small radius to ensure good aerodynamic efficiency. Figure 2 shows the external skin of the aircraft, which can be divided into a center fuselage section that contains the propulsive flowpath, and the delta wings. To accomplish its mission, the vehicle requires a large amount of fuel in the form of LH2, which serves as propellant for the engine. In order to accommodate all the fuel the tanks need to be defined to have the maximum volume capacity while maintaining an efficient structural behavior. In this sense, the aforementioned project envisaged a structural arrangement of multiple overlapped lobes within the wings with the additional benefit of serving as a support system for the propulsion system inside the fuselage.

Based on the design of the LAPCAT MR2.4 vehicle, the STRATOFLY MR3 was developed a few years later [5]. Figure 3 shows a comparison between the tank arrangements of the two vehicles. The STRATOFLY MR3 contains gaps between some of the lobes to allow sufficient space for the landing gears and cabin entrances. For this reason, this solution was found to be weaker [6] and, therefore, heavier than the one used for the LAPCAT MR2.4 [7]. Therefore, an optimum continuous set of lobes from the tip to the end of the wing is sought in this research, following the idea proposed during the LAPCAT project (Fig. 3a).

Although previous studies have shown promising results for this concept [8], a detailed trade-off study is needed to analyze the benefits of the different multi-lobe configurations. In this sense, this research proposes an optimization to improve the volumetric and structural performance of multi-lobe configurations, obtaining integral solutions for hypersonic vehicles.

2 Hydrogen tanks for hypersonic vehicles

The overall objective of a hypersonic vehicle tank design is to have a safe, lightweight, and thermally efficient storage system. Hydrogen can be stored at high pressures as a compressed gas (CGH2) or at low temperatures as a liquid (LH2). CGH2 must be highly compressed to store the highest amount of energy in a given volume. Although CGH2 tanks are currently under development by other engineering disciplines, such as the automotive field [9], these concepts are not applicable to an aircraft. The need for larger tanks to accommodate the required onboard fuel would imply a heavier design that could meet the strength requirements. As an alternative, the temperature of the hydrogen can be reduced until reaching the liquid state, which requires smaller and lighter tanks due to the significantly lower pressures to accommodate the required fuel mass.

One of the predominant technological barriers when designing liquid hydrogen-powered aircraft is storing enough fuel mass onboard to achieve a sufficient range for the mission. Although it possesses a higher specific energy (energy per unit mass) than other jet fuels, cryogenic hydrogen has significantly lower energy density (energy per unit volume), which implies lightweight but large volumes to be integrated within the airframe.

Once the capacity requirements are stated, it is necessary to take into account some key considerations: (1) LH2 must be maintained between its freezing and boiling points, \(-259^{\circ }\hbox {C}\) and \(-253^{\circ }\hbox {C}\), respectively, leaving a very small margin for operation, (2) the temperature gradient between the skin and the cryogenic fuel must be managed. Values of up to \(\Delta T = 1250^{\circ }\hbox {C}\) can be reached due to aerothermodynamic heating at hypersonic speeds, (3) a material that is not permeable to hydrogen must be used to reduce fuel leaks, and (4) coefficient of thermal expansion (CTE) mismatches must be avoided between the components of the wall. There are other important issues associated with cryogenic tank design, such as vapor management, fuel transfer, cryogenic pumping, and the possibility of using the cold energy of the fuel for regenerative cooling. However, these system design issues are beyond the scope of this work and thus will not be addressed here.

With respect to material selection, fiber-reinforced composites are not considered an option because of the permeability of the resins. When this material is subjected to high strains resulting from mechanical and thermal loads, it is no longer capable of holding the hydrogen without significant losses. Additionally, the thermal cycling associated with repeated filling and draining can cause material fatigue damage in the form of matrix microcracking, which can result in further leakage [10]. For these reasons, in this study, a linerless tank of a dense metallic material was chosen as the first choice and a methodology to minimize costs, weight and compatibility issues.

Although material selection for the tank wall is a critical issue in the early stages of the design, its architecture, regarding number of panels, attachments, and insulation, is an important interrelated concern. In this case, a double-walled tank construction is considered, capable of isolating the bending stresses produced by the temperature gradient. This kind of design was already proposed during the development of the X-33 reusable launch vehicle [11]. In Fig. 4 the thermal protection system (TPS) panel concept used to attach the external skin to the stiffeners of the X-33 cryogenic tanks is shown.

X-33 metallic TPS panel concept. Modified from [12]

The structural behavior of the wall is greatly influenced by the parameters controlling overall geometry, such as cylinder radii, intersection angles, and tapering. This means that the shape of the tank will affect its ability to accommodate bending stresses, which arise at the intersection of the lobes and will propagate throughout the skin. Therefore, certain geometric shapes, such as the sphere, can better minimize bending stresses within the tank wall, whereas cylindrical configurations or more complex conformal geometries may require a tailored stiffening scheme to resist bending.

Large lightweight tanks would collapse due to the compressive forces caused by their own weight, unless there is an internal pressure that can induce tensile forces to counteract this effect, preventing buckling. For this reason, LH2 tanks with large size and relatively small thickness need an internal pressure to be stable. In a study by Steelant et al. [13], the LAPCAT MR2 cryogenic tanks were subjected to an internal over pressure of 0.5 bar. This value will be used in the tank analysis herein.

3 Two-lobe tank configuration

As an illustrative example, the behavior of a two bubble tank with a web subject to internal pressure forces is analyzed. The finite-element model exclusively comprises quadrilateral elements without transverse shear deformations [14], denoted CQUAD4 in Nastran. The material is an aluminum alloy 2219 with a T87 temper, which is considered to be one of the best materials for fabrication of manned spacecraft tankage [15]. The model consists of two consecutive lobes with identical radii (r) with an overlap defined by the intersection of angles \(\phi \) and \(\theta \) (Fig. 5). At the intersection of the two lobes, vertical webs are disposed to transfer the circumferential hoop stresses from top to bottom. The connection between the skins and the web is usually called a Y-junction, because of its shape. Apart from being structurally efficient, this strategy has the additional benefit of reducing dynamic loads caused by the internal sloshing [16].

The model shown in Fig. 6 is used to analyze the structural behavior of the tank. The pressure applied has a value of 50 kPa, the length is 4 m and it was meshed using 0.05 m sized quadrilateral elements. The web and the shell have equal thicknesses of 1 mm. Results are only discussed in a 1 m wide stripe at the center of the model, as shown in Fig. 6. The purpose is to capture the general behavior of the tank and to avoid local effects at the border. The longitudinal and tangential displacements are constrained in the highlighted nodes. In this manner, the tank is able to freely deform without incurring in a matrix singularity.

Figure 7 shows different stress distributions at various selected angles. As can be seen, the lower stress values are obtained with an angle of \(\phi ={60}^{\circ }\); this is because the vertical components of the lobe hoop stresses balance out with the tensile stress of the web, as shown in the free body diagram presented in Fig. 8, which depicts the membrane forces at the Y-junction. For two lobes of equal radii, the vertical equilibrium equation can be written as

Therefore, at the Y-junction, for \(\phi = 60\), the web and the lobes should have exactly the same membrane axial stresses, but bending stresses propagate throughout the lobe. For this reason, instead of defining a single thickness for the entire tank, several patches can be set for a more precise subdivision. Consequently, the thickness can be better adjusted, resulting in a lighter design. By performing an optimization to minimize the weight in the \(\phi = 60\) configuration, an improved thickness distribution is obtained, as shown in Fig. 9. If the number of patches is increased, we can reduce the weight even further. Going from 8 patches per lobe to 32, the mass is reduced from 21.092 kg to 20.516 kg, which represents a 2.7% reduction. But this approach will increase the complexity of the design, being necessary to choose a compromise solution between complexity and weight.

4 Parametric model

To assess the benefits and drawbacks of different tank geometries, a parametric model is needed to obtain the mechanical behavior of any arbitrary configuration. To make this model robust, we chose a set of parameters that avoid non-feasible configurations. Furthermore, continuous variables are preferred, so that a gradient-based optimization algorithm could be applied afterwards.

4.1 Definition of geometrical parameters

As mentioned previously, the main benefit of the multi-lobe configuration is to be able to adapt to any external geometry, e.g., a hypersonic wedge wing or a rounded waverider fuselage body. This is referred to in the literature as a conformal tank. To obtain a general approach, the top and bottom boundaries are considered as straight lines. Therefore, in case of a curved boundary, the path will be approximated to a polygonal line.

The parametrization approach is outlined in Fig. 10. Initially, the radius of each lobe was considered as a parameter, because the angles \(\phi \) and \(\theta \), as well as the center of each lobe, could be obtained geometrically by imposing tangency at the top and bottom lines. However, this approach led to non-feasible, non-overlapping, strictly tangent or coincident configurations. In order to avoid all of these pitfalls, the problem was formulated from a different perspective. By fixing the initial and final lobes to be tangent to the top, bottom and corresponding side boundaries, the subsequent circles were defined by a parameter \(p_i\). This parameter represents the overlap between the current lobe and the previous one, lying between a left bound \(lb_i\) and a right bound \(rb_i\), which act as margins to avoid coincident and tangent lobes. The overlap value \(p_i\) is expressed as a percentage of its domain, because the interval \([lb_i, rb_i]\) depends on the previous values of \(p_i\), and cannot be known a priori.

An important caveat is not knowing how many lobes a given configuration will produce. To address this, a sufficiently large number of \(p_i\) parameters is provided and the circles are created sequentially until a circle intersects the global bound line (Fig. 10). In this sense, we could provide as parameters n values of \(p_i\), but only a fraction \(N < n\) of the circles will be included in the design. If gb corresponds to the coordinate of the global bound line, we can express that a circle will be created while the following condition is satisfied:

The parameters \(p_i\) define three tangent lines to each circle, as shown in Fig. 11. From these lines, the geometric values \(r_i\), \(\phi _i\), \(\theta _i\), and the center \(c_i\) of each circle can be calculated. If the two oblique lines are symmetric with respect to the x-axis and are defined through equations \(y_1=ax+b\) and \(y_2=-ax-b\), and the vertical line is defined through equation \(x = d\), then

and the intersection angles can be obtained by applying the cosine law in the triangle formed by the two radii and the distance between the centers \(\Delta c = c_{i+1} - c_{i}\):

4.2 Finite-element model

Once the geometry is completely defined, a meshing strategy has to be employed. To do so, each lobe and web are subdivided into the required number of arches and extruded through the length of the tank. The resulting surfaces are meshed using a transfinite mapping algorithm [17] obtaining a compatible high quality mesh. To generate the model in a systematic fashion, a reliable numbering system has to be put into place. Figure 12 shows the patches and numbering system of a four lobed design, with four patches on the boundary cylinders, two in the intermediate ones, and three on each web.

The boundary conditions are imposed on the center section of each lobe in the same manner as previously explained in Fig. 6. Regarding the loads, the internal pressure and the external aerodynamic forces produced by the high-speed velocity regime are imposed. Figure 13 shows a side view of the wing of the LAPCAT vehicle. Here \(\text {Ma}_\infty \), \(\text {Ma}_1\), and \(\text {Ma}_2\) are the free-stream, after shock, and after expansion Mach, respectively. The wedge defined by \(\delta _1\) produces an oblique shock forming an angle \(\beta \) with the bottom of the vehicle, and a Prandtl–Meyer expansion fan at the convex corner of the top surface, defined by \(\delta _2\) The bottom shock increases the aerodynamic pressure, which can be obtained using local Rankine–Hugoniot shock wave equations.

5 Optimization strategy

The optimization problem is formulated to solve the following question: Which is the optimal multi-lobe configuration that provides the maximum internal volume while maintaining structural strength and stability? Although a conformal tank solution would have the maximum fuel capacity, it is not the most structurally efficient. For that reason, a trade-off between weight and volumetric efficiency must be sought. This requires design variables that control the number and shape of lobes, as well as the thicknesses of the skin and webs. The general formulation of the optimization problem is as follows:

where M is the mass of the tank, \( Vv \) the void volume or volume without fuel, as shown in Fig. 14, \(\sigma _j\) the Von Mises stress and \(\lambda _1\) the first buckling eigenvalue. The design variables are the number of lobes n, the radii of the lobes \(\textbf{r}\), and the thicknesses of each tank panel \(\textbf{t}\). The problem is challenging for the following reasons:

-

1.

The number of lobes n is a discrete variable, so no continuous optimization technique can be directly applied.

-

2.

There are non-feasible configurations, non-intersecting and tangent lobes, that could make the optimization algorithm unstable.

-

3.

The size of the vector of design variables depends on n, that is, \(\dim \textbf{r} = f_r(n)\) and \(\dim \textbf{t} = f_t(n)\). As a result, the size for the Jacobian would not be constant, and a gradient-based algorithm cannot be used.

-

4.

At least a local minimum exists for each n-lobe configuration, making the results highly dependent on the initial design.

Issues 1 and 2 can be solved using the parametric model defined in the previous section, as it converts the discrete variables into a series of continuous variables that cannot produce problematic designs. Issue 3 is addressed by proposing a nested optimization problem, with the outer loop in charge of modifying the position parameters \(\textbf{p}\) and the inner loop iterating over the thicknesses \(\textbf{t}\). Lastly, a genetic algorithm applied in the outer loop allows to explore the whole design domain, solving issue 4. Furthermore, in order to improve the design, two steps, denoted as global and local search are performed to reach the final solutions. These steps are explained in the following sections.

5.1 Global search

The parametric finite-element model requires a set of position values \(\textbf{p}\). The size of this vector depends on the number of lobes of the tank, which is not known a priori. For this reason, the size of \(\textbf{p}\) should be determined prior to the optimization process. Its dimension will be equal to the maximum number of lobes that can fit in a given geometry, according to the bounds imposed on each lobe. This value can be obtained by fixing \(p_i\) to its minimum value \(lb_i\), until the right edge of the last lobe (\(c_i + r_i\)) does not reach the global bound limit gb. Taking this into consideration, \( \dim {\textbf{p}}\) corresponds to n, that can be obtained by solving Eq. 6:

As mentioned above, the discrete nature of the problem leads to discontinuities in the general behavior of the system. As an example, Fig. 15 represents the evolution in the value of a general response R, for a 3- and 4-lobe design. When the parameter \(p_1\) is between the left bound \(lb_1\) and the transition limit, a 4-lobe configuration is generated. This is due to the gap between the second and last lobes, which would lead to an incomplete configuration, so an additional lobe is needed. By increasing the parameter \(p_1\), the tangency with the last lobe is reached, marking the transition limit, hence the discontinuity in the value of R. For values between the transition limit and the right boundary \(rb_1\), a 3-lobe design is generated. Thus, it can be concluded that at least one local minimum will exist within each continuous segment. Therefore, any local search algorithm will probably stop after finding one. This peculiarity requires an algorithm capable of sampling the entire design domain, such as a genetic algorithm. For this purpose, the MOGA algorithm [18] was chosen, which consists of an evolutionary algorithm that can handle multiple objective functions to obtain a set of non-dominated designs.

To handle the varying number of thicknesses considered as design variables \(\textbf{t}\), an optimization loop is nested in each MOGA sample, leaving only the modification of the parameter \(\textbf{p}\) to the outer loop. In this manner, a thickness optimization is performed for each design proposed by the genetic algorithm, thus obtaining an optimum mass value for each sampled point. This nested optimization can be computed very efficiently by calculating the sensitivities by the direct method [19, 20]. This is, given any response variable \(\psi \) that is presumed to be a function of displacements \(\textbf{u}(x)\) and the design variable x, its derivative will be

Therefore, obtaining the displacement derivative is sufficient to calculate any sensitivity of a response. To do so, the general discretized equilibrium equation \(\textbf{K}(x) \textbf{u}(x) = \textbf{F}(x)\) is derived to obtain

where \(\textbf{K}\) and \(\textbf{F}\) are the stiffness matrix and load vector, respectively. The right hand side of Eq. 8 is usually denoted as the pseudo-load vector, and can be obtained by deriving the elemental contributions of the load vector and the stiffness matrix. The new system of equations is analogous to the one use to solve the original problem, so no additional matrix factorization is needed, improving the computational time considerably. The global search can be formulated as follows:

As can be seen, the outer level only modifies the position parameters \(\textbf{p}\) and the inner level the thicknesses \(\textbf{t}\). The genetic algorithm is in charge of proposing a new population based on the overlap between lobes, and, in turn, the inner level will obtain its corresponding minimum weight design. As a result, a pair of values—volume capacity vs. weight—is obtained for each individual, which are ranked by the genetic algorithm. Then, a new population is proposed and the process is repeated. When the maximum number of evaluations is reached, the process is terminated, and the non-dominated designs are selected and passed as inputs to the next step.

5.2 Local search

For each non-dominated design of the previous step, a final local optimization is performed in a single level. In this step, the mass and the void volume are weighted into a single objective function. A gradient-based algorithm is employed, where the side constraints of the thicknesses are tightened, so that the number of lobes does not vary. To make the algorithm efficient, all gradients must be provided to the optimizer [21]. The four required derivatives are calculated as follows: (1) the derivatives of the mass, stresses, and buckling factor with respect to the thickness \(\partial M / \partial \textbf{t}\), \(\partial \sigma _j / \partial \textbf{t}\), and \(\partial \lambda _1 / \partial \textbf{t}\) are obtained by the structural sensitivity analysis explained in the previous section, (2) the derivatives of the void volume with respect to the overlap parameters \(\partial Vv / \partial \textbf{p}\) are obtained by algorithmic differentiation [22], since the void volume is calculated using standard Python functions, (3) the derivatives of the void volume with respect to the thicknesses \(\partial Vv / \partial \textbf{t}\) are assumed to be 0, and (4) the derivatives of the mass with respect to the overlap parameters \(\partial M / \partial \textbf{p}\) are obtained with the following relation:

where \( Pe _i\) being the perimeter of each patch along the cross-section. The derivatives of the perimeter with respect to the overlap parameters \(\frac{\partial Pe _i}{\partial \textbf{p}}\) are also obtained by algorithmic differentiation. The optimization problem can be formulated as follows:

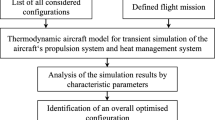

where \(\alpha \) represents the weighting parameter to perform the multi-objective optimization. In this paper, the value of this parameter is approximated as the vertical distance to the normalized utopia point. In this manner, the previously obtained design is improved and some designs can even match. Once the process is completed, the final Pareto front is obtained. The flow diagrams of the two steps are depicted in Fig. 16.

5.3 Implementation

The methodology was implemented using a variety of software tools and libraries. The process is summarized in Fig. 17. The main process pipeline is controlled by the task runner software, that executes sequentially the following steps: (1) first the radii, positions and angles are calculated from the overlap parameters through a Python script. Furthermore, through the autograd library [23], the derivatives of the perimeters and void volumes are calculated using algorithmic differentiation. (2) Then, the geometric parameters are used to generate the partitioned geometry using the openCascade kernel [24]. (3) Importing that geometry into gmsh [25], the quadrilateral mesh is obtained. (4) Afterwards, using pyNastran [26], the FEM model containing the material, properties, loads, and boundary conditions is built in Nastran format. (5) The Nastran solver analyzes the model to obtain all the structural responses and derivatives through the direct method, and finally, (6) a post-processing Python script parses the hdf5 format file into the required objectives, constraints and derivatives. To manage the global and local search optimizations, dakota [18] is used as an interface software to control parallel execution, file management, and the correct handling the parameters of the optimization algorithm. The global search is controlled by the MOGA algorithm [18], the nested optimization uses MSC ADS [27], and the local search uses the DOT algorithm [28].

All global search evaluations were performed in parallel in a high-performance computing cluster. Likewise, each of the gradient-based optimizations for each of the non-dominated designs were also computed in parallel to speed out the process.

6 Results

To evaluate the aforementioned procedure, we optimized the tank configuration inside the wedge section defined by the lines with equation \(y_1 = 0.05 x + 1.0 \) and \(y_2 = -0.05 x - 1.0\), from \(x=0\) to a width of 10 m. This implies a total clearance between 2 m (left bound) and 3 m (right bound). Each model generated was automatically meshed with an element size of 0.05 m and subdivided with eight patches on the boundary lobes, four on the intermediate ones, and three on the webs. In the longitudinal direction, the model is partitioned in five modules, but only the results of the central one are discussed. Aerodynamic loads correspond to a cruise condition at an altitude of 35,000 m, \( Ma = 8.0\), and \({0}^{\circ }\) angle of attack. The material is aluminum alloy 2219-T87 with a Young modulus of 85 GPa, Poisson ratio of 0.33, and density of \(2840~\hbox {kg/m}^{3}\).

The initial design of the optimization corresponds to equal overlap parameters of 0.1 and thicknesses of 1 mm. A limit of 58 MPa was imposed to the major principal stress of each element. The global search approach was limited to 2500 model evaluations. All the mass and void volume values are shown in Fig. 18. It is clear from the results that the values are organized in clusters corresponding to the number of lobes, albeit there are some outliers that correspond to very poor designs.

Extracting the list of non-dominated designs, we obtain five configurations that are used as starting points for the last step. As can be seen in Fig. 19, the three designs of nine lobes coalesce into a single optimum design, and the solutions with five and six lobes are slightly improved.

The number of lobes, \(M^{*}\), and \( Vv ^{*}\) are summarized in Table 1. In addition, the lobe, thickness, and stress distribution are presented in Figs. 20, 21, and 22, respectively.

When each optimum design is analyzed, it is observed that the most volumetrically efficient are those with more lobes, but they correspond to the heaviest designs. In contrast, the lightest designs are the ones with less lobes. The mass varies 5.0% across the Pareto front, and the available volume changes to almost 120%. Calculating the ratio of mass to void volume, the most efficient design is among the cluster of the heavier optima (\( Vv < 2\) in Fig. 19). The configurations in the cluster with lower mass (\(M < {500}\,\hbox {kg}\) in Fig. 19) exhibit lobes closer together in the narrowest part of the wing, and further apart towards the right bound. This is because the membrane stresses in a cylinder are proportional to its radius and, therefore, the lobes on the wider side of the section will be heavier, since a thicker shell will be needed to withstand the loads. Therefore, the optimizer favors putting more lobes towards the narrow side if the constraints are also satisfied. The minimum mass design is a nine-lobe configuration, with small gaps between lobes. In this scenario, the skin of the tank is closer to the outer mold line of the wing, hence less volume is wasted. However, the main drawback is that a higher number of webs is required, significantly increasing the mass of the multi-lobe configuration.

The optimization results demonstrate that the proposed approach performs trade-offs between volumetric and structural performance in an effective way, taking into account the chosen objectives. In this sense, a multi-functional design can now be adapted to any external shape by concatenating the required number of linear segments.

7 Conclusions

In this work, a systematic approach to obtain optimum multi-lobe pressure tank configurations for hypersonic aircraft is presented. To this end, a multi-objective approach was performed to simultaneously minimize the tank weight and maximize its volumetric capacity. In a first stage, a parametric finite-element model was developed to fit a wedge geometry representative of waverider wings. Then, the parametric model was incorporated into an optimization problem organized in two levels: the outer level corresponds to the global search where several designs are proposed to explore the entire design domain. All of them are optimized using a gradient-based algorithm. As a result, a set of non-dominated designs are passed to the next optimization step, where the designs are improved.

The optimization was performed including pressure and aerodynamic loads relative to a cruise speed of \( Ma = 8\) and \(0^{\circ }\) angle of attack. During the process, finite-element meshes were automatically generated, where each mesh contains approximately 70 000 quadrilateral elements with bending and membrane properties. The optimization problem was solved using as design variables ten relative overlap positions and a non-fixed number of thickness variables that depend on the number of lobes. Stress constraints were imposed on all aluminum elements of the skin and webs. The solution of these problems required 10 h of wall time using 50 processors in parallel to solve the set of models. The computational cost was reduced by efficient derivative calculation integrated into gradient-based algorithms combined with global search methods.

A Pareto front was obtained, providing insights into the structural and volumetric trade-offs of a multi-lobe design. The proposed methodology can handle the problem complex geometries in a robust manner, allowing for more tailored designs that could not be addressed using traditional approaches. It is a suitable solution for designing tanks not only hypersonic vehicles, but also for other nonstandard airplane configurations or heavy-lift launch vehicles.

References

Ardema, M.: Structural weight analysis of hypersonic aircraft. Nasa Technical Report Server (1972)

Robinson, J.C., Dutton, J.H.: Stress and buckling analysis of a double-bubble tank structure. In: NASTRAN: Users’ Experiences, p. 19 (1972)

Dorsey, J., Myers, D., Martin, C.: Reusable launch vehicle tank/intertank sizing trade study. In: 38th Aerospace Sciences Meeting and Exhibit. American Institute of Aeronautics and Astronautics, Reno,NV,U.S.A. (2000). doi: https://doi.org/10.2514/6.2000-1043

Steelant, J., Varvill, R., Walton, C., Defoort, S., Hannemann, K., Marini, M.: Achievements Obtained for Sustained Hypersonic Flight within the LAPCAT-II project. In: 20th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. American Institute of Aeronautics and Astronautics, Glasgow, Scotland (2015). doi: https://doi.org/10.2514/6.2015-3677

Viola, N., Ferretto, D., Fusaro, R., Scigliano, R.: Performance assessment of an integrated environmental control system of civil hypersonic vehicles. Aerospace 9(4), 201 (2022). https://doi.org/10.3390/aerospace9040201

Rodríguez-Segade, M., Hernández, S., Díaz, J.: Multi-bubble scheme and structural analysis of a hypersonic stratospheric flight vehicle. Aerosp Sci Technol (2022). https://doi.org/10.1016/j.ast.2022.107514

Steelant, J., van Duijn, M.: Structural Analysis of the LAPCAT-MR2 Waverider Based Vehicle. In: 17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. American Institute of Aeronautics and Astronautics, San Francisco, California (2011). doi: https://doi.org/10.2514/6.2011-2336

Malfroy, J.: Design and optimization of a tapered multi-bubble tank for hypersonic aircraft. PhD thesis, KU Leuven (2022)

Aceves, S.M., Espinosa-Loza, F., Ledesma-Orozco, E., Ross, T.O., Weisberg, A.H., Brunner, T.C., Kircher, O.: High-density automotive hydrogen storage with cryogenic capable pressure vessels. Int. J. Hydrog. Energy 35(3), 1219–1226 (2010). https://doi.org/10.1016/j.ijhydene.2009.11.069

Letchworth, G.: X-33 Reusable Launch Vehicle Demonstrator, Spaceport and Range. In: AIAA SPACE 2011 Conference & Exposition. American Institute of Aeronautics and Astronautics, Long Beach, California (2011). doi: https://doi.org/10.2514/6.2011-7314

Sawyer, J.W., Hodge, J., Moore, B., Snyder, K.: Aerothermal test of thermal protection systems for X-33 reusable launch vehicle. In: AIP Conference Proceedings, pp. 1087–1100. AIP, Albuquerque, New Mexico (USA) (1999). doi: https://doi.org/10.1063/1.57501

Myers, D.E., Martin, C.J., Blosser, M.L.: Parametric weight comparison of advanced metallic, ceramic tile, and ceramic blanket thermal protection systems. Technical Report TM-2000-210289, NASA (2000)

Steelant, J., van Duijn, M.: Structural Analysis of the LAPCAT-MR2 Waverider Based Vehicle. In: 17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. American Institute of Aeronautics and Astronautics, San Francisco, California (2011). doi: https://doi.org/10.2514/6.2011-2336

Reddy, J.N.: An Introduction to the Finite Element Method, 3rd, ed McGraw-Hill Series in Mechanical Engineering. McGraw-Hill Higher Education, New York (2006)

Engstrom, W.L.: Determination of design allowable properties. Fracture of 2219-T87 aluminum alloy. Technical Report D180-14480-1 (March 1972)

Ibrahim, R.A.: Liquid sloshing dynamics. Dynamics 9780521838856, 948 (2005). https://doi.org/10.1017/CBO9780511536656

Gordon, W.J., Thiel, L.C.: Transfinite mappings and their application to grid generation. Appl. Math. Comput. 10–11, 171–233 (1982). https://doi.org/10.1016/0096-3003(82)90191-6

User’s Manual. Dakota Documentation, Sandia National Laboratories (2022)

Kim, N.H.: Sensitivity Analysis. In: Blockley, R., Shyy, W. (eds.) Encyclopedia of Aerospace Engineering, p. 497. John Wiley & Sons, Ltd, Chichester, UK (2010). doi: https://doi.org/10.1002/9780470686652.eae497

Hernandez, S.: Metodos de Diseño Optimo de Estructuras, 1st edn. Colegio de Ingenieros de Caminos Canales y Puertos, Spain (1990)

Martins, J.R.R.A., Hwang, J.T.: Review and unification of methods for computing derivatives of multidisciplinary computational models. AIAA J. 51(11), 2582–2599 (2013). https://doi.org/10.2514/1.J052184

Naumann, U.: The Art of Differentiating Computer Programs: An Introduction to Algorithmic Differentiation. Environments, and Tools. Society for Industrial and Applied Mathematics, Philadelphia, Software (2011)

Maclaurin, D., Duvenaud, D., Johnson, M., Adams, R.P.: Autograd: Reverse-mode differentiation of native python. Autograd: Reverse-Mode Differentiation of Native Python (2015). cited By 25

Open CASCADE SAS. Open CASCADE technology (version 7.5.0) (2020)

Geuzaine, C., Remacle, J.-F.: Gmsh: A 3-D finite element mesh generator with built-in pre- and post-processing facilities. Int. J. Numer. Meth. Eng. 79(11), 1309–1331 (2009). https://doi.org/10.1002/nme.2579

Doyle, S., Danial, A. Pynastran: A Python-Based Interface Tool for Nastran’s File Formats (2014)

Design Sensitivity and Optimization User’s Guide. Nastran Documentation, MSC (2021)

DOT Users Manual. Version 4.20, Vanderplaats Research and Devolpment (1995)

Acknowledgements

The research leading to these results has been conducted under Grant PID2019-108307RB-I00 funded by MCIN/AEI/10.13039/501100011033. The authors also acknowledge funding received from the Galician Government through research grant ED431C 2021/33.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rodríguez-Segade, M., Steelant, J., Hernáández, S. et al. Design optimization of multi-functional multi-lobe cryogenic fuel tank structures for hypersonic vehicles. CEAS Space J 15, 813–826 (2023). https://doi.org/10.1007/s12567-023-00486-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12567-023-00486-z