Abstract

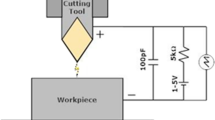

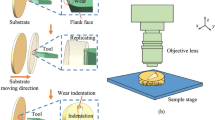

Work coordinate setup in an ultra-precision machine tool is one of the important tasks to fabricate a structure at the desired position with high accuracy. Setting up the work coordinate is very challenging because it requires high precision, direct measurement, and non-contact preferred. This paper proposes a new method to measure the relative distance between tool-work materials using the electrical breakdown where current flows through electrical insulator when an applied voltage is higher than the breakdown voltage. The applied voltage is linearly proportional to the relative distance in nanoscale. Experiment with Al6061, SS316, AISI1018 steel, and OFHC Cu work materials, and WC and CBN tools showed a successful and easy application of this method in work coordinate setup with 70 nm uncertainty at low applied voltage. Surface damages by the electrical breakdown of Al6061, SS316, AISI1018 steel, and OFHC Cu were not found at less than or equal to 1, 2, and 3 V, respectively. An automated detection test was conducted and found approaching speed of 0.1 mm/min without surface damage. Standard uncertainty analysis validated the confidence of the proposed method.

Similar content being viewed by others

References

Dornfeld, D., Min, S., & Takeuchi, Y. (2006). Recent advances in mechanical micromachining. CIRP Annals - Manufacturing Technology, 55, 745–768. https://doi.org/10.1016/j.cirp.2006.10.006

Liu, X., Wei, W., Yuan, J., Tao, Y., Li, Y., & Huang, Y. (2021). A high accuracy method for the field dynamic balancing of rigid spindles in the ultra-precision turning machine. International Journal of Precision Engineering and Manufacturing, 22, 1829–1840. https://doi.org/10.1007/s12541-021-00585-z

Touch Probes. (n.d.). Retrieved from October 22, 2018 from https://www.heidenhain.com/de_DE/produkte/tastsysteme/.

After The Fall whitepaper - updated global numbers FINAL refresh.pdf (n.d.). Retrieved March 19, 2019 from https://lp.servicemax.com/rs/020-PCR-876/images/After%20The%20Fall%20whitepaper%20-%20updated%20global%20numbers%20FINAL%20refresh.pdf.

Bourne, K. A., Jun, M. B., Kapoor, S. G., & DeVor, R. E. (2008). An acoustic emission-based method for determining contact between a tool and workpiece at the microscale. Journal of Manufacturing Science and Engineering, 130, 031101. https://doi.org/10.1115/1.2917285

Min, S., Lidde, J., Raue, N., & Dornfeld, D. (2011). Acoustic emission based tool contact detection for ultra-precision machining. CIRP Annals - Manufacturing Technology, 60, 141–144. https://doi.org/10.1016/j.cirp.2011.03.079

Min, S., Sangermann, H., Mertens, C., & Dornfeld, D. (2008). A study on initial contact detection for precision micro-mold and surface generation of vertical side walls in micromachining. CIRP Annals, 57, 109–112. https://doi.org/10.1016/j.cirp.2008.03.068

Turner, S. L., Rabani, A., Axinte, D. A., & King, C. W. (2014). Dynamic ultrasonic contact detection using acoustic emissions. Ultrasonics, 54, 749–753. https://doi.org/10.1016/j.ultras.2013.10.002

Kakinuma, Y., & Kamigochi, T. (2012). External sensor-less tool contact detection by cutting force observer. Procedia CIRP, 2, 44–48. https://doi.org/10.1016/j.procir.2012.05.037

Kakinuma, Y., & Nagakari, S. (2017). Sensor-less micro-tool contact detection for ultra-precision machine tools utilizing the disturbance observer technique. CIRP Annals - Manufacturing Technology, 66, 385–388. https://doi.org/10.1016/j.cirp.2017.04.056

Popov, K., Dimov, S., Ivanov, A., Pham, D. T., & Gandarias, E. (2010). New tool-workpiece setting up technology for micro-milling. International Journal of Advanced Manufacturing Technology, 47, 21–27. https://doi.org/10.1007/s00170-009-2055-2

Roy, S., Mandal, S., & Nagahanumaiah, N. (2016). Tool–workpiece contact detection in micro-milling using wireless-aided accelerometer sensor. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 230, 182–187. https://doi.org/10.1177/0954405415573850

Liu, X., & Zhu, W. (2017). Development of a fiber optical occlusion based non-contact automatic tool setter for a micro-milling machine. Robotics and Computer-Integrated Manufacturing, 43, 12–17. https://doi.org/10.1016/j.rcim.2016.04.002

Yoshioka, H., Shinno, H., Sawano, H., & Tanigawa, R. (2014). Monitoring of distance between diamond tool edge and workpiece surface in ultraprecision cutting using evanescent light. CIRP Annals - Manufacturing Technology, 63, 341–344. https://doi.org/10.1016/j.cirp.2014.03.129

Lee, H.-H., Yang, M.-Y., Shin, W.-C., Ro, S.-K., & Park, J.-K. (2011). A compact high-precision optical sensor for three-dimensional tool-origin compensation. International Journal of Precision Engineering and Manufacturing, 12, 543–549. https://doi.org/10.1007/s12541-011-0068-x

Wadhwa, C. L. (2007). High voltage engineering. New Age International.

Germer, L. H., & Haworth, F. E. (1948). A low voltage discharge between very close electrodes. Physical Review, 73, 1121–1121. https://doi.org/10.1103/PhysRev.73.1121

Slade, P. G., & Taylor, E. D. (2002). Electrical breakdown in atmospheric air between closely spaced (0.2 μm–40 μm) electrical contacts. IEEE Transactions on Components and Packaging Technologies, 25, 390–396. https://doi.org/10.1109/TCAPT.2002.804615

Torres, J.-M., & Dhariwal, R. S. (1999). Electric field breakdown at micrometre separations. Nanotechnology, 10, 102. https://doi.org/10.1088/0957-4484/10/1/020

Lee, R.-T., Chiou, Y.-C., & Chung, H.-H. (2001). Arc erosion behaviour of silver electric contacts in a single arc discharge across a static gap. IEE Proceedings-Science, Measurement and Technology, 148, 8–14. https://doi.org/10.1049/ip-smt:20010181

Peschot, A., Bonifaci, N., Lesaint, O., Valadares, C., & Poulain, C. (2014). Deviations from the Paschen’s law at short gap distances from 100 nm to 10 μm in air and nitrogen. Applied Physics Letters, 105, 123109. https://doi.org/10.1063/1.4895630

Virwani, K. R., Malshe, A. P., & Rajurkar, K. P. (2007). Understanding dielectric breakdown and related tool wear characteristics in nanoscale electro-machining process. CIRP Annals, 56, 217–220. https://doi.org/10.1016/j.cirp.2007.05.098

Go, D. B., & Venkattraman, A. (2014). Microscale gas breakdown: ion-enhanced field emission and the modified Paschen’s curve. Journal of Applied Physics, 47, 503001. https://doi.org/10.1088/0022-3727/47/50/503001

Radmilović-Radjenović, M., & Radjenović, B. (2007). The influence of ion-enhanced field emission on the high-frequency breakdown in microgaps. Plasma Sources Science and Technology, 16, 337. https://doi.org/10.1088/0963-0252/16/2/017

Yang, Z., Hoffmann, S., Lichtenwalner, D. J., Krim, J., & Kingon, A. I. (2011). Resolution of the transfer direction of field-evaporated gold atoms for nanofabrication and microelectromechanical system applications. Applied Physics Letters, 98, 044102. https://doi.org/10.1063/1.3545846

Chung, D. K., Shin, H. S., Park, M. S., Kim, B. H., & Chu, C. N. (2011). Recent researches in micro electrical machining. International Journal of Precision Engineering and Manufacturing, 12, 371–380. https://doi.org/10.1007/s12541-011-0049-0

Acknowledgements

Authors gratefully acknowledge the help of Dr. Edward Hwang and kind support from the FANUC Corporation, Japan, for the loan of the ROBONANO α-0iB, one of the latest ultra-precision machine tool, to MIN LAB at UW-Madison. This work also was supported by the Hongik University new faculty research fund.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maeng, S., Min, S. Work Coordinate Setup in the Ultra-precision Machine Tool Using Electrical Breakdown. Int. J. Precis. Eng. Manuf. 24, 745–753 (2023). https://doi.org/10.1007/s12541-023-00779-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00779-7