Abstract

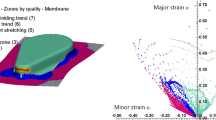

Volumetric and geometric errors should be periodically checked to ensure that the accuracy of machine tools remains within the tolerable range. However, existing methods require complex devices, and are thus unsuitable for cost-effective interim error checks. We present a simple, rapid and cost-effective method for interim error checks. The measurement paths are constructed using a virtual polyhedron; volumetric errors are checked by calculating the coordinates of the vertices using the measured side lengths. The tool is sequentially moved to each vertex, and the side lengths are measured using a double ball-bar. As the virtual polyhedron is composed of virtual regular tetrahedrons, the relationships between the coordinates of the vertices and side lengths are unique. Linear scale and squareness errors are measured using an error synthesis model with a least-squares approach. The method was applied to a real machine tool, and performance was verified by confirming that the maximum L2 norm of volumetric error is improved from 57.6 to 32.8 μm after compensating for the measured geometric errors. Thus, the validity of the proposed method was confirmed by an improvement of 43% in volumetric error. The measurement results were confirmed by the circular tests of ISO 230-4; the peak-to-valley radial deviation improved from 16.0 to 11.2 μm after compensation, and the proposed method contributed to a 30% improvement in the radial deviation.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

Abbreviations

- m :

-

Number of vertices of the virtual polyhedron

- c i :

-

Linear scale error of the linear axis i (i = X, Y, Z) (μm/mm)

- s ij :

-

Squareness error of linear axis j around axis i (i, j = X, Y, Z) (rad)

- L :

-

Nominal side length of the virtual polyhedron (mm)

- δL i,j :

-

Measured deviations of the side lengths between the i-th and j-th vertices of the virtual polyhedron (i, j = 1, …, m) (mm)

- P i,n (x i,n, y i,n, z i,n):

-

Nominal coordinates of the i-th vertex of the virtual polyhedron (i = 1, …, m) (mm)

- P i,c (x i,c, y i,c, z i,c):

-

Coordinates of the i-th vertex of the virtual polyhedron in {P} (i = 1, …, m) (mm)

- P i,a (x i,a, y i,a, z i,a):

-

Coordinates of the i-th vertex of the virtual polyhedron in {R} (i = 1, …, m) (mm)

- δP i,c (δx i,c, δy i,c, δz i,c):

-

Positional errors between Pi,c and Pi,n (i = 1, …, m) (mm)

- δP i,a (δx i,a, δy i,a, δz i,a):

-

Volumetric errors at the i-th vertex (i = 1, …, m) (mm)

- {i}:

-

Coordinate system of axis i, (i = X, Y, Z)

- {P}, {R} :

-

Virtual polyhedron and reference coordinate systems, respectively

- \({{\varvec{\uptau}}}_{i}^{j}\) :

-

4 × 4 homogeneous transformation matrix from the j to i coordinate system

References

Okafor, A. C., & Ertekin, Y. M. (2000). Derivation of machine tool error models and error compensation procedure for three axes vertical machining center using rigid body kinematics. International Journal of Machine Tools and Manufacture, 40, 1199–1213. https://doi.org/10.1016/S0890-6955(99)00105-4

Yang, S. H., & Lee, K. I. (2021). Machine tool analyzer: A device for identifying 13 position–independent geometric errors for five–axis machine tools. The International Journal of Advanced Manufacturing Technology, 115, 2945–2957. https://doi.org/10.1007/s00170-021-07341-7

Ramesh, R., Mannan, M. A., & Poo, A. N. (2000). Error compensation in machine tools—A review Part I: Geometric, cutting–force induced and fixture–dependent errors. International Journal of Machine Tools and Manufacture, 40, 1235–1256. https://doi.org/10.1016/S0890-6955(00)00009-2

ISO 230-1. (2012). Test code for machine tools—Part 1: Geometric accuracy of machines operating under no-load or quasi-static conditions. ISO.

Lee, J. C., Lee, H. H., & Yang, S. H. (2016). Total measurement of geometric errors of a three–axis machine tool by developing a hybrid technique. International Journal of Precision Engineering and Manufacturing, 17, 427–432. https://doi.org/10.1007/s12541-016-0053-5

ISO 230–7. (2015). Test code for machine tools—Part 7: Geometric accuracy of axes of rotation. ISO.

Schwenke, H., Knapp, W., Haitjema, H., Weckenmann, A., Schmitt, R., & Delbressine, F. (2008). Geometric error measurement and compensation of machines – An update. CIRP Annals Manufacturing Technology, 57, 660–675. https://doi.org/10.1016/j.cirp.2008.09.008

Ibaraki, S., & Knapp, W. (2012). Indirect measurement of volumetric accuracy for three–axis and five–axis machine tools: A review. International Journal of Automation Technology, 6, 110–124. https://doi.org/10.20965/ijat.2012.p0110

ISO 230–2. (2014). Test code for machine tools—Part 2: Determination of accuracy and repeatability of positioning of numerically controlled axes. ISO.

Sun, G., He, G., Zhang, D., Yao, C., & Tian, W. (2020). Body diagonal error measurement and evaluation of a multiaxis machine tool using a multibeam laser interferometer. The International Journal of Advanced Manufacturing Technology, 107, 4545–4559. https://doi.org/10.1007/s00170-020-05275-0

Ibaraki, S., & Hiruya, M. (2021). A novel scheme to measure 2D error motions of linear axes by regulating the direction of a laser interferometer. Precision Engineering, 67, 152–159. https://doi.org/10.1016/j.precisioneng.2020.09.011

Lee, H. H., Lee, D. M., & Yang, S. H. (2014). A technique for accuracy improvement of squareness estimation using a double ball–bar. Measurement Science and Technology, 25, 094009. https://doi.org/10.1088/0957-0233/25/9/094009

Schwenke, H., Schmitt, R., Jatzkowski, P., & Warmann, C. (2009). On–the–fly calibration of linear and rotary axes of machine tools and CMMs using a tracking interferometer. CIRP Annals, 58, 477–480. https://doi.org/10.1016/j.cirp.2009.03.007

Zha, J., Wang, T., Li, L., & Chen, Y. (2020). Volumetric error compensation of machine tool using laser tracer and machining verification. The International Journal of Advanced Manufacturing Technology, 7–8, 2467–2481. https://doi.org/10.1007/s00170-020-05556-8

ISO 230–4. (2005). Test code for machine tools—Part 4: Circular tests for numerically controlled machine tools. ISO.

Pahk, H. J., Kim, Y. S., & Moon, J. H. (1994). A new technique for volumetric error assessment of CNC machine tools incorporating ball bar measurement and 3D volumetric error model. International Journal of Machine Tools and Manufacture, 37, 1583–1596. https://doi.org/10.1016/S0890-6955(97)00029-1

Wang, Z., Wang, D., Yu, S., Li, X., & Dong, H. (2021). A reconfigurable mechanism model for error identification in the double ball bar test of machine tools. International Journal of Machine Tools and Manufacture, 165, 103737. https://doi.org/10.1016/j.ijmachtools.2021.103737

Lee, K. I., Lee, J. C., & Yang, S. H. (2013). The optimal design of a measurement system to measure the geometric errors of linear axes. The International Journal of Advanced Manufacturing Technology, 66, 141–149. https://doi.org/10.1007/s00170-012-4312-z

Liebrich, T., Bringmann, B., & Knapp, W. (2009). Calibration of a 3D–ball plate. Precision Engineering, 33, 1–6. https://doi.org/10.1016/j.precisioneng.2008.02.003

Mayer, J. R. R. (2012). Five–axis machine tool calibration by probing a scale enriched reconfigurable uncalibrated master balls artefact. CIRP Annals – Manufacturing Technology, 61, 515–518. https://doi.org/10.1016/j.cirp.2012.03.022

ISO 10791–2. (2001). Test conditions for machining centres Part 2: Geometric tests for machines with vertical spindle or universal heads with vertical primary rotary axis. ISO.

Lee, K. I., Shin, D. H., & Yang, S. H. (2017). Parallelism error measurement for the spindle axis of machine tools by two circular tests with different tool lengths. The International Journal of Advanced Manufacturing Technology, 88, 2883–2887. https://doi.org/10.1007/s00170-016-8999-0

Yang, S. H., Kim, K. H., Park, Y. K., & Lee, S. G. (2004). Error analysis and compensation for the volumetric errors of a vertical machining centre using a hemispherical helix ball bar test. The International Journal of Advanced Manufacturing Technology, 23, 495–500. https://doi.org/10.1007/s00170-003-1662-6

Lee, K. I., Lee, H. H., & Yang, S. H. (2017). Interim check and practical accuracy improvement for machine tools with sequential measurements using a double ball–bar on a virtual regular tetrahedron. The International Journal of Advanced Manufacturing Technology, 93, 1527–1536. https://doi.org/10.1007/s00170-017-0582-9

Yang, S. H., Lee, H. H., & Lee, K. I. (2017). Interim check and compensation of geometric errors to improve volumetric error of machine tools. Journal of Korean Society for Precision Engineering, 35, 623–627. https://doi.org/10.7736/KSPE.2018.35.6.623

Ziegert, J. C., & Mize, C. D. (1994). The laser ball bar: A new instrument for machine tool metrology. Precision Engineering, 16, 259–267. https://doi.org/10.1016/0141-6359(94)90002-7

Lee, D. M., & Yang, S. H. (2010). Mathematical approach and general formulation for error synthesis modeling of multi–axis system. International Journal of Modern Physics B, 24, 2737–2742. https://doi.org/10.1142/S0217979210065556

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (Nos. 2020R1C1C100330011 and 2019R1A2C2088683).

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (Nos. 2020R1C1C100330011 and 2019R1A2C2088683).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, KI., Jeon, HK., Lee, JC. et al. Use of a Virtual Polyhedron for Interim Checking of the Volumetric and Geometric Errors of Machine Tools. Int. J. Precis. Eng. Manuf. 23, 1133–1141 (2022). https://doi.org/10.1007/s12541-022-00666-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00666-7