Abstract

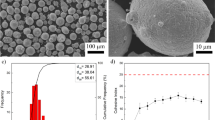

In this study, a fuel cell bipolar plate is formed using indirect squeeze casting which uses liquid materials and stamping process which uses solid state materials. The formability of these two types of processes is discussed. The shapes of die cavity in the indirect squeeze casting and that in the stamping are same. The materials filling rate during indirect squeeze casting was increased as punch pressure that pushes molten aluminum into cavity of die is increased. A breakage occurs when load of upper die which presses aluminum plate 0.1mm thick is at 20 kN. When load of upper die is at 15 kN, the maximum channel depth is achieved. Though precise channel shape can be achieved by the indirect squeeze casting, the thickness of bipolar plate is larger by around three times than that formed by stamping. An irregular-shaped channel is obtained in the bipolar plate formed by stamping due to problems of wrinkle, springback, and flatness. The current density of unit cell with casted aluminum bipolar plate with TiN layer and stamped aluminum bipolar plate are 421 and 410 mA cm−2 at 0.6 V, respectively.

Similar content being viewed by others

References

Rajagopal, S., “Squeeze Casting: A Review and Update,” Journal of Applied Metalworking, vol. 1, no. 4, pp. 3–14, 1981.

Gallerneault, M., Durrant, G., and Cantor, B., “The Squeeze Casting of Hypoeutectic Binary Al-Cu,” Metallurgical and Materials Transactions A, vol. 27, no. 12, pp. 4121–4132, 1996.

Kim, S. W., Durrant, G., Lee, J. H., and Cantor, B., “The Effect of Die Geometry on the Microstructure of Indirect Squeeze Cast and Gravity Die Cast 7050 (Al-6.2 Zn-2.3 Cu-2.3 Mg) Wrought Al Alloy,” Journal of Materials Science, vol. 34, no. 8, pp. 1873–1883, 1999.

Zhang, Q., Masoumi, M., and Hu, H., “Influence of Applied Pressure on Tensile Behaviour and Microstructure of Squeeze Cast Mg Alloy AM50 with Ca Addition,” Journal of Materials Engineering and Performance, vol. 21, no. 1, pp. 38–46, 2012.

Rosso, M., Peter, I., Bivol, C., Molina, R., and Tonno, G., “Development of Industrial Components by Advanced Squeeze Casting,” International Journal of Material Forming, vol. 3, no. 1, pp. 787–790, 2010.

Mahabunphachai, S., Cora, Ö. N., and Koç, M., “Effect of Manufacturing Processes on Formability and Surface Topography of Proton Exchange Membrane Fuel Cell Metallic Bipolar Plates,” Journal of Power Sources, vol. 195, no. 16, pp. 5269–5277, 2010.

Turan, C., Cora, Ö. N., and Koç, M., “Effect of Manufacturing Processes on Contact Resistance Characteristics of Metallic Bipolar Plates in PEM Fuel Cells,” International Journal of Hydrogen Energy, vol. 36, no. 19, pp. 12370–12380, 2011.

Jin, C. K., Koo, J. Y., and Kang, C. G., “Fabrication of Stainless Steel Bipolar Plates for Fuel Cells using Dynamic Loads for the Stamping Process and Performance Evaluation of a Single Cell,” International Journal of Hydrogen Energy, vol. 39, no. 36, pp. 21461–21469, 2014.

Kwon, H. J., Jeon, Y. P., and Kang, C. G., “Effect of Progressive Forming Process and Processing Variables on the Formability of Aluminium Bipolar Plate with Microchannel,” The International Journal of Advanced Manufacturing Technology, vol. 64, no. 5–8, pp. 681–694, 2013.

Wang, H. and Turner, J., “Reviewing Metallic PEMFC Bipolar Plates,” Fuel Cells, vol. 10, no. 4, pp. 510–519, 2010.

Tawfik, H., Hung, Y., and Mahajan, D., “Metal Bipolar Plates for PEM Fuel Cell-A Review,” Journal of Power Sources, vol. 163, no. 2, pp. 755–767, 2007.

Seo, Y. H., Kim, H. J., Jang, W. K., and Kim, B. H., “Development of Active Breathing Micro PEM Fuel Cell,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 1, no. 2, pp. 101–106, 2014.

Hwang, Y. S., Choi, H., Cho, G. Y., Lee, Y. H., and Cha, S. W., “Effect of Compression Thickness on Performance of Gas Diffusion Layer of Direct Methanol Fuel Cells,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 1, no. 3, pp. 215–221, 2014.

Jin, C. K., Jeong, M. G., and Kang, C. G., “Fabrication of Titanium Bipolar Plates by Rubber Forming and Performance of Single Cell using Tin-Coated Titanium Bipolar Plates,” International Journal of Hydrogen Energy, vol. 39, no. 36, pp. 21480–21488, 2014.

Jeong, M. G., Jin, C. K., Hwang, G. W., and Kang, C. G., “Formability Evaluation of Stainless Steel Bipolar Plate Considering Draft Angle of Die and Process Parameters by Rubber Forming,” Int. J. Precis. Eng. Manuf., vol. 15, no. 5, pp. 913–919, 2014.

Hung, J. C. and Lin, C. C., “Fabrication of Micro-Flow Channels for Metallic Bipolar Plates by a High-Pressure Hydroforming Apparatus,” Journal of Power Sources, vol. 206, pp. 179–184, 2012.

Jin, C. K. and Kang, C. G., “Fabrication Process Analysis and Experimental Verification for Aluminum Bipolar Plates in Fuel Cells by Vacuum Die-Casting,” Journal of Power Sources, vol. 196, no. 20, pp. 8241–8249, 2011.

Jin, C. K. and Kang, C. G., “Fabrication by Vacuum Die Casting and Simulation of Aluminum Bipolar Plates with Micro-Channels on both Sides for Proton Exchange Membrane (PEM) Fuel Cells,” International Journal of Hydrogen Energy, vol. 37, no. 2, pp. 1661–1676, 2012.

Jin, C. K., Jang, C. H., and Kang, C. G., “Die Design Optimization of Die Casting for Fabrication of Fuel Cell Aluminum Bipolar Plate with Micro-Channel through Casting Simulation and Experimental Investigation,” Journal of Mechanical Science and Technology, vol. 27, no. 10, pp. 2997–3003, 2013.

Jin, C. K., Jung, M. G., and Kang, C. G., “Fabrication of Aluminum Bipolar Plates by Semi Solid Forging Process and Performance Test of TiN Coated Aluminum Bipolar Plates,” Fuel Cells, vol. 14, no. 4, pp. 551–560, 2014.

Jin, C. K., Jang, C. H., and Kang, C. G., “Effect of the Process Parameters on the Formability, Microstructure, and Mechanical Properties of Thin Plates Fabricated by Rheology Forging Process with Electromagnetic Stirring Method,” Metallurgical and Materials Transactions B, vol. 45, no. 1, pp. 193–211, 2014.

Wang, H., Teeter, G., and Turner, J., “Investigation of a Duplex Stainless Steel as Polymer Electrolyte Membrane Fuel Cell Bipolar Plate Material,” Journal of the Electrochemical Society, vol. 152, no. 3, pp. B99–B104, 2005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, CK., Kang, CG. A comparative study on the formability of aluminum bipolar plate with channels using indirect squeeze casting and stamping. Int. J. Precis. Eng. Manuf. 16, 1233–1238 (2015). https://doi.org/10.1007/s12541-015-0160-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0160-8